Preparation method of moisturizing instant rice

A technology of instant rice and production methods, which is applied in food preparation, food shaping, multi-step food processing, etc. It can solve the problems of loose extrusion products, affecting appearance and texture, poor stability of single-screw extrusion, etc., and achieve moderate Hardness and chewiness, improved texture and appearance, improved adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

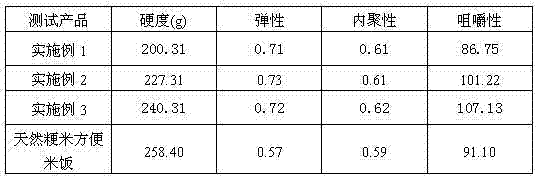

Examples

Embodiment 1

[0022] Embodiment 1 The preparation steps of the present embodiment moisturizing type instant rice are as follows:

[0023] (1) Pre-cooking of raw materials: Add 300g of drinking water to 300g of broken rice (japonica rice), and cook for 2.5min in a rice cooker with a rated power of 700W to make the degree of gelatinization 40%;

[0024] (2) Drying: Filter out the excess water after pre-cooking, and then dry the material in a drying oven at 60°C to control its moisture content to 22%;

[0025] (3) Pulverization: pulverize the dried material to a particle size of 0.425mm with a pulverizer;

[0026] (4) Extrusion and cutting molding: Put the pulverized material into the feeder and enter it into the twin-screw extruder for extrusion. The parameters of the extruder are set as: screw speed 90r / min, the sleeve from the feed port The four-stage temperature of the outlet is 30°C, 40°C, 50°C, and 70°C in sequence; the extruded material is extruded through the rice grain-shaped...

Embodiment 2

[0029] The preparation steps of the moisturizing type instant rice of the present embodiment are as follows:

[0030] (1) Pre-cooking of raw materials: Add 300g of drinking water to 300g of broken rice (japonica rice), and cook for 2.5min in a rice cooker with a rated power of 700W to make the degree of gelatinization 50%;

[0031] (2) Drying: Filter out the excess water after pre-cooking, and then dry the material in a drying oven at 60°C to control its moisture content to 23%;

[0032] (3) Pulverization: pulverize the dried material to a particle size of 0.425mm with a pulverizer;

[0033] (4) Extrusion and cutting molding: Put the pulverized material into the feeder and enter it into the twin-screw extruder for extrusion. The parameters of the extruder are set as: screw speed 100r / min, the sleeve from the feed port The four-stage temperature of the outlet is 33°C, 43°C, 53°C, and 73°C in sequence; the extruded material is extruded through the rice grain-shaped die hole...

Embodiment 3

[0036] The preparation steps of the moisturizing type instant rice of the present embodiment are as follows:

[0037] (1) Pre-cooking of raw materials: Add 300g of drinking water to 300g of broken rice (japonica rice), and cook for 2.5min in a rice cooker with a rated power of 700W to make the gelatinization degree 60%;

[0038] (2) Drying: Filter out the excess water after pre-cooking, and then dry the material in a drying oven at 60°C to control its moisture content to 24%;

[0039] (3) Pulverization: pulverize the dried material to a particle size of 0.425mm with a pulverizer;

[0040] (4) Extrusion and cutting molding: Put the pulverized material into the feeder and enter it into the twin-screw extruder for extrusion. The parameters of the extruder are set as: screw speed 120r / min, the sleeve from the feed port The four-stage temperature of the outlet is 35°C, 45°C, 55°C, and 75°C in sequence; the extruded material is extruded through the rice grain-shaped die hole, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com