Reinforced concrete hollow floor plate

A technology for reinforced concrete and hollow floor slabs, which is applied to floors, buildings, building components, etc., can solve the problems of inconvenient transportation and easy deformation of box-shaped frames.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

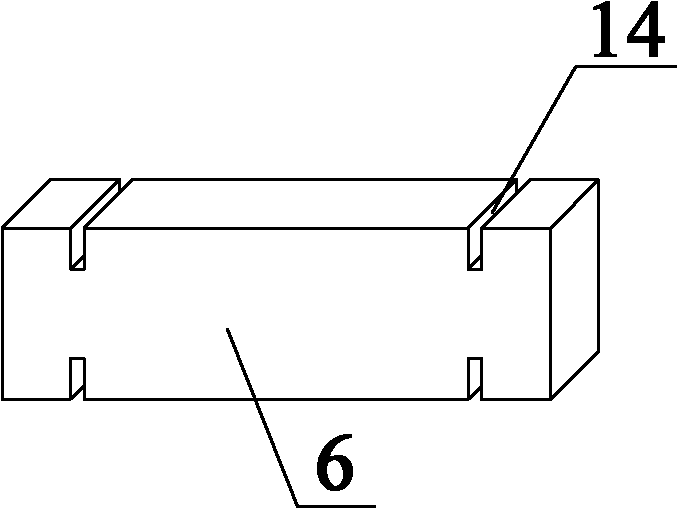

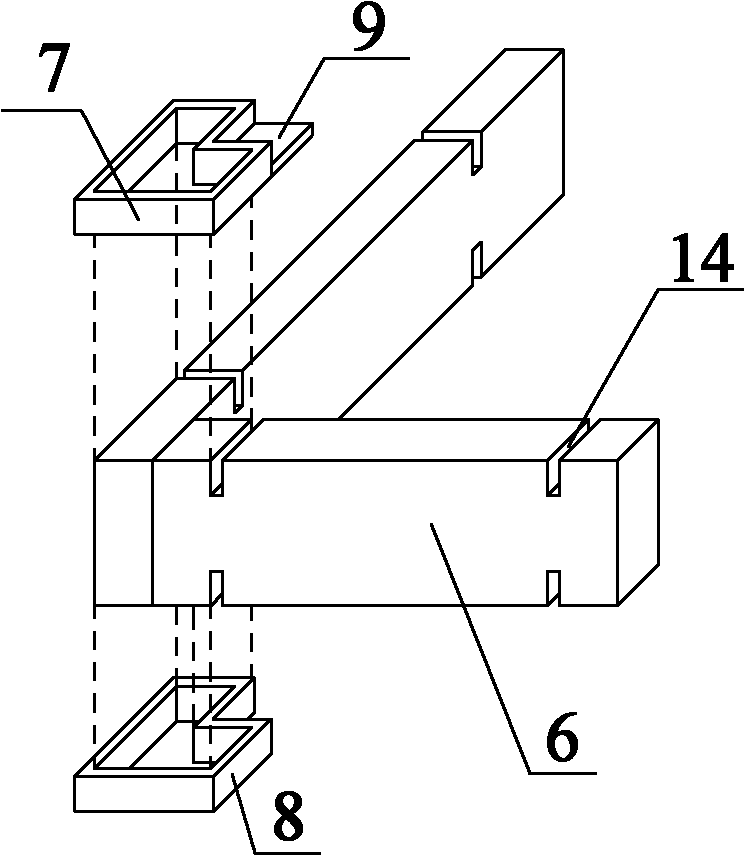

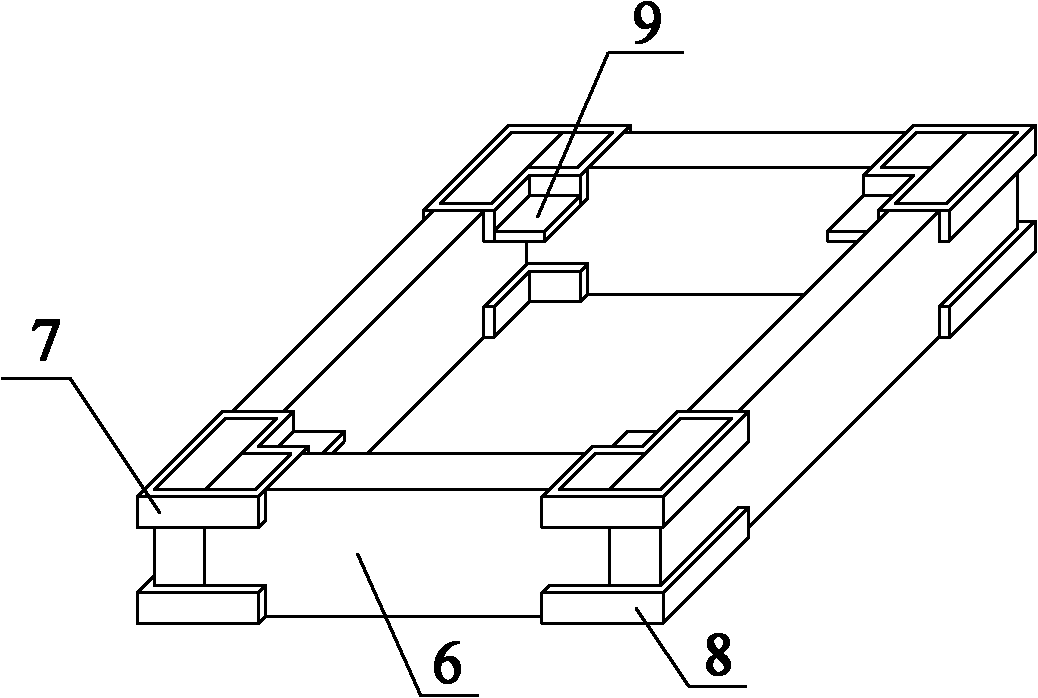

[0027] The invention is attached Figure 1-13 As shown, a reinforced concrete hollow floor slab includes a reinforced concrete prefabricated component 1 and cast-in-place concrete 2. The prefabricated component 1 is composed of a prefabricated bottom plate 3, a prefabricated side wall 4, and a prefabricated roof 5. The present invention is characterized in that the described prefabricated side The wall 4 is assembled by two or more prefabricated boards 6 through the top connector 7 and the bottom connector 8 , and the prefabricated top board 5 is placed on the shelving part 9 protruding from the top connector 7 . There are grooves 14 at the top and bottom of both ends of the prefabricated panel 6, and the top connector 7 and the bottom connector 8 are installed in the groove 14. The connectors have strong rigidity, and two or more prefabricated panels can be connected together. 6 are connected into integral prefabricated side wall 4.

[0028] The present invention is also cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com