High-pressure solid phase crystallization method

A polysilicon thin film and thin film thickness technology, which is applied in the field of solar cell material preparation, can solve problems such as hindering the industrialization of polysilicon thin film photovoltaic technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

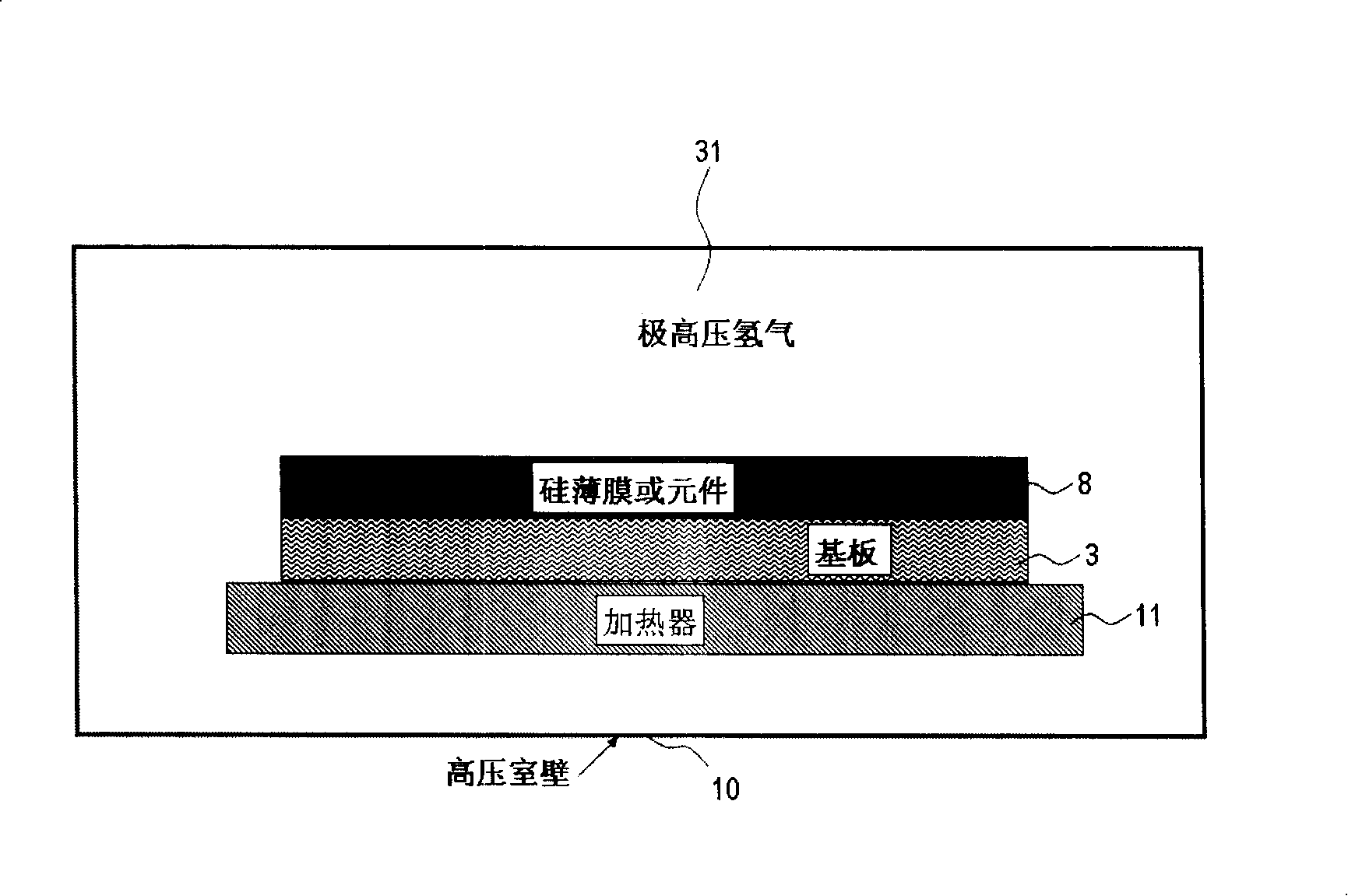

[0009] Use plasma-enhanced chemical vapor deposition equipment to form hydrogenated amorphous silicon with a thickness not exceeding 5 microns on a substrate 3 at a temperature not exceeding 300°C, and then place the material in a sealable high-temperature and high-pressure processing device 10 Place the hydrogenated amorphous silicon film or its element 8 deposited on the substrate 3 on a support base 11 with a heating function, introduce a gas whose main component contains hydrogen 31 into the box, and make its pressure reach no less than 200 Atmospheric high pressure, preferably not less than 1000 atmospheres, and maintain the substrate temperature at not lower than 600°C. In this high temperature and high pressure state, it is maintained for 2-20 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com