Light emitting diode with two-segment pins

A light-emitting diode, two-stage technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of easy deformation and misalignment of the PIN pins of LED lights, and achieve side-emitting effects, simple installation, and fast assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

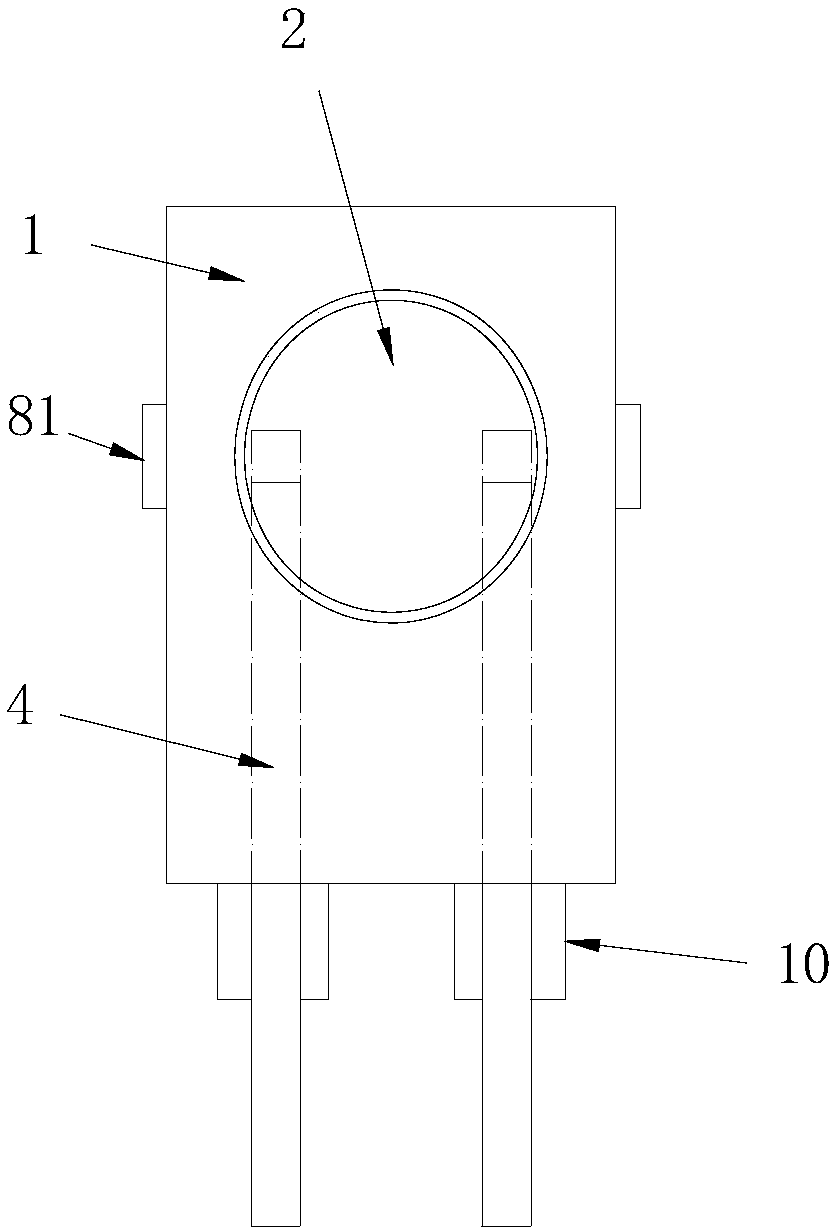

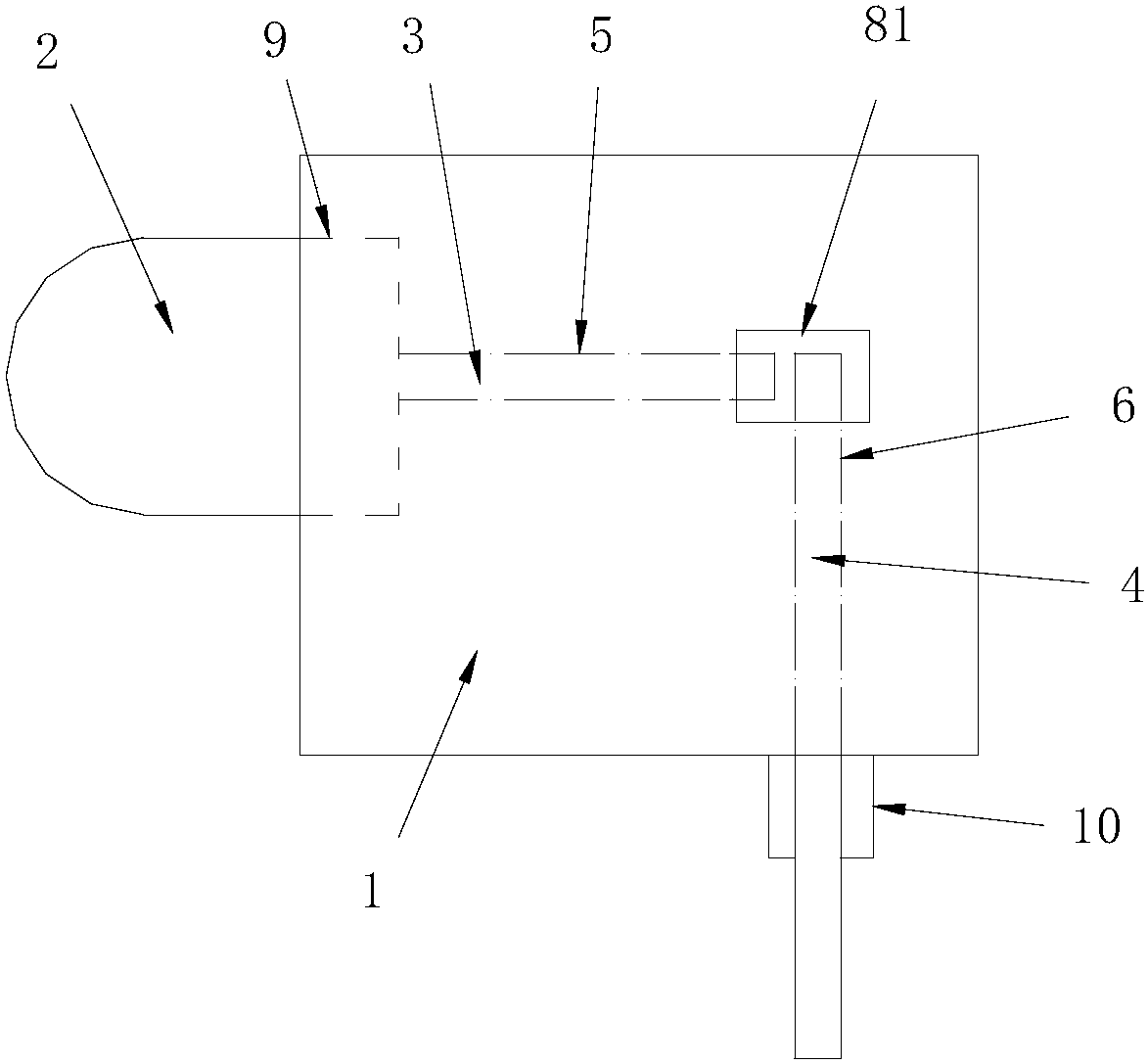

[0020] Embodiment one, see appendix Figure 1-2 As shown, a light-emitting diode with two-stage PIN pins in this embodiment includes a lamp housing 1, an LED lamp 2, and two pins, both pins are arranged on the LED lamp 2, and the pins pass through The lamp housing 1 is provided with horizontal straight through holes 5 and vertical straight through holes 6 which are perpendicular to each other. Each pin is composed of two branch pins, namely the first branch pin 3 and the second branch pin. Two branch pins 4, one end of the first branch pin 3 is connected to the LED lamp 2, the other end of the first branch pin 3 penetrates the horizontal straight through hole 5, and the lamp housing 1 is provided with an LED lamp accommodating groove 9, The base of the LED lamp 2 is installed in the LED lamp accommodating groove 9; the second branch pin 4 penetrates the vertical straight through hole 6, and one end of the two branch pins located in the lamp housing 1 is connected by a conducti...

Embodiment 2

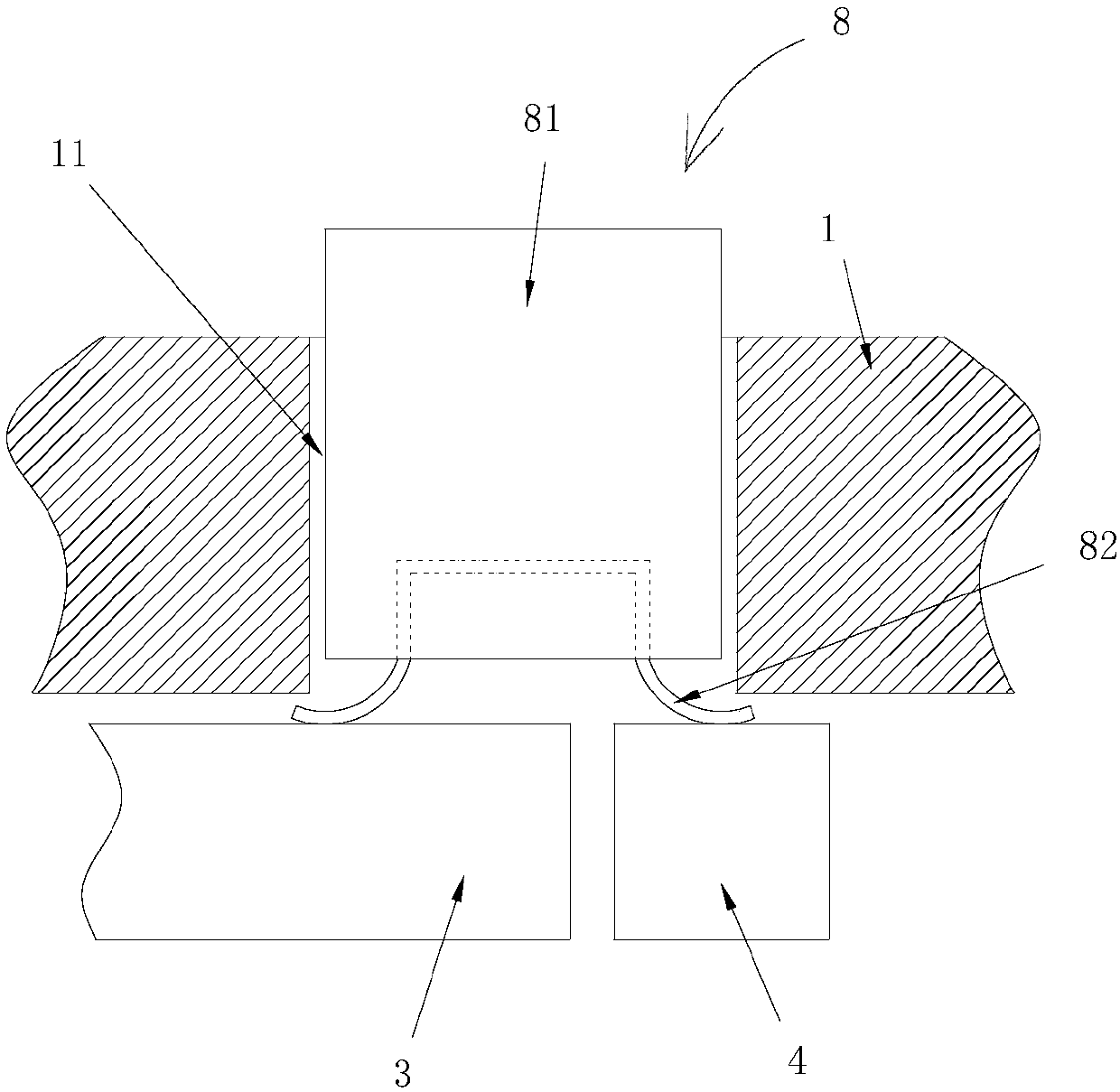

[0022] Embodiment two, see appendix Figure 4 , 5 As shown, the difference between the conductive elastic sheet in this embodiment and the first embodiment is that the conductive elastic sheet adopts a plug-in conductive elastic sheet 7, and the plug-in conductive elastic sheet 7 includes a first casing 71 and a first conductive elastic sheet 72. The first casing 71 Built in the lamp housing 1, the first shell 71 is provided with a conductive shrapnel groove 73, the two ends of the first conductive shrapnel 72 are set in the conductive shrapnel groove 73, and the middle part of the first conductive shrapnel 72 has an arched part 74, arched The raised portion 74 protrudes from the first housing 71 and presses one end of the two branch pins located in the lamp housing 1 by the elasticity of the first conductive elastic piece 72 . The arched part 74 and the branch pin are fixed by the structure of the groove 75 and the protrusion 76. The groove 75 in this embodiment is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com