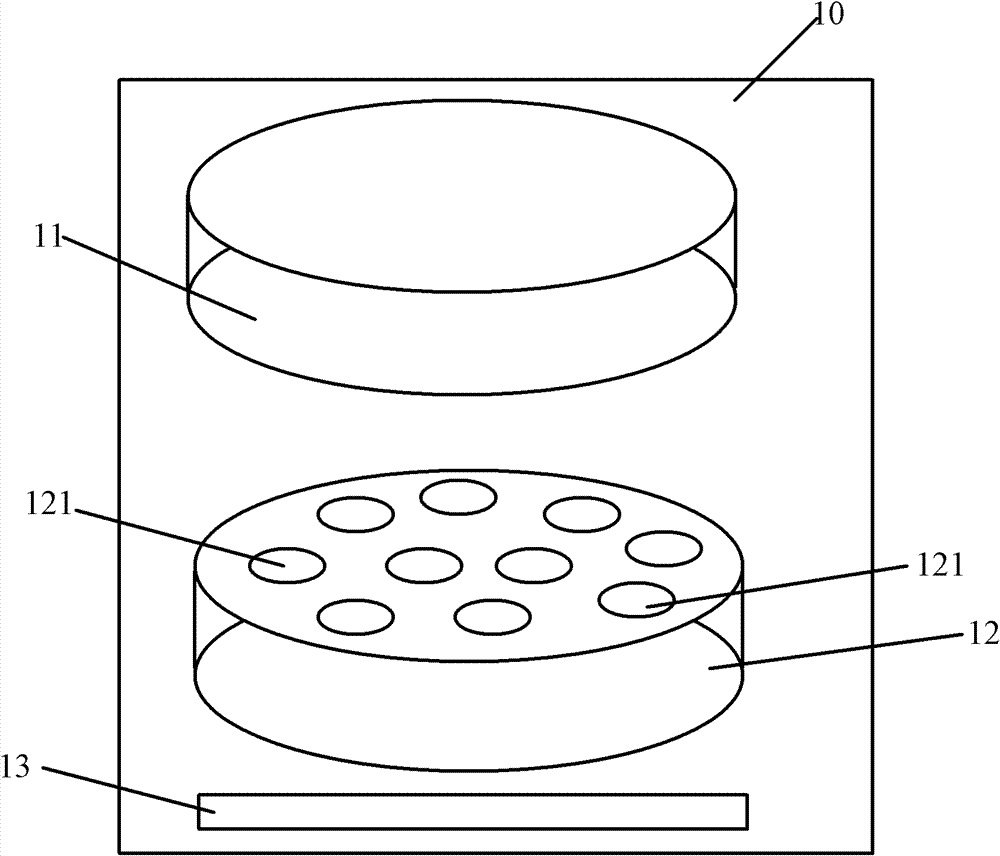

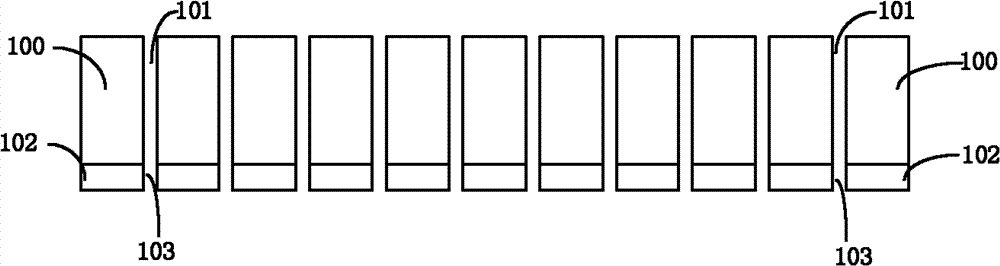

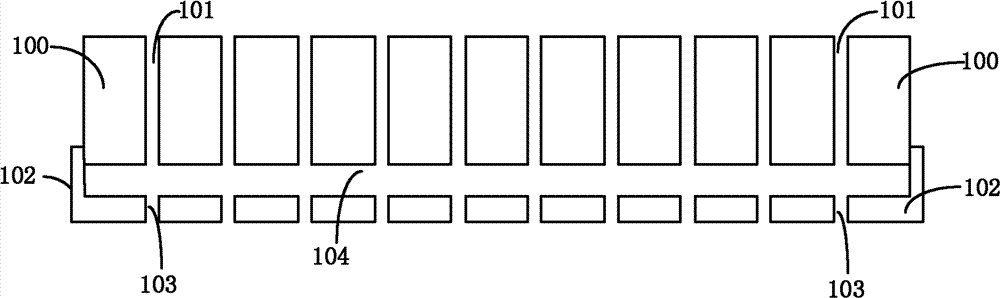

Spray head used in chemical vapor deposition process

A technology of chemical vapor deposition and chemical deposition, which is applied in the field of spray heads of chemical vapor deposition process, can solve the problems of low quality of epitaxial material layer, and the capacity and efficiency of chemical vapor deposition equipment cannot meet the requirements of the application, so as to reduce the possibility of Sex and shedding amount, reduced cleaning and maintenance, lessened the effect of vortex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Existing showerheads are usually made of stainless steel, and the temperature of the surface of the showerhead near the substrate is usually lower than 200 degrees Celsius. During the chemical vapor deposition process, a deposition layer will also be formed on the surface of the shower head near the substrate, but since the material of the surface of the shower head near the substrate is stainless steel, and the surface The temperature is very low, resulting in a relatively sparse and loose texture of the deposition layer formed on the surface. During the chemical vapor deposition process, the deposition layer formed on the surface of the shower head near the substrate side is easy to fall off from the surface. Dust particles are formed to contaminate the epitaxial material layer grown on the substrate and generate impurity defects. Therefore, after each chemical vapor deposition process is completed, a lot of cleaning and cleaning work must be carried out. Doing so af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com