Cleaning system and cleaning method for automotive metal plate stamping die

A stamping die and cleaning system technology, applied in the field of cleaning, can solve problems such as increased production costs, high overall costs, and damage to filter devices, and achieve the effects of prolonging service life, improving decontamination capabilities, and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

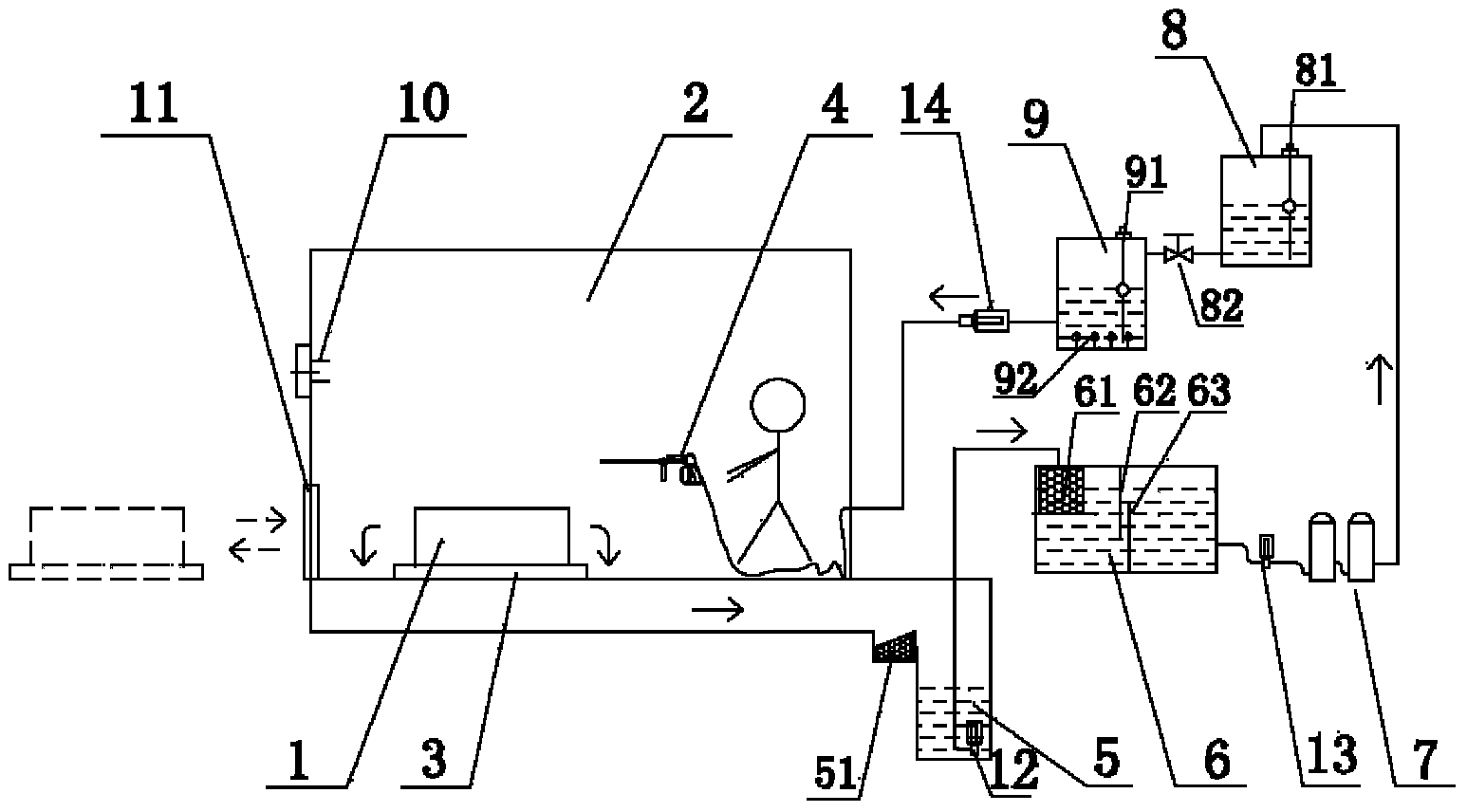

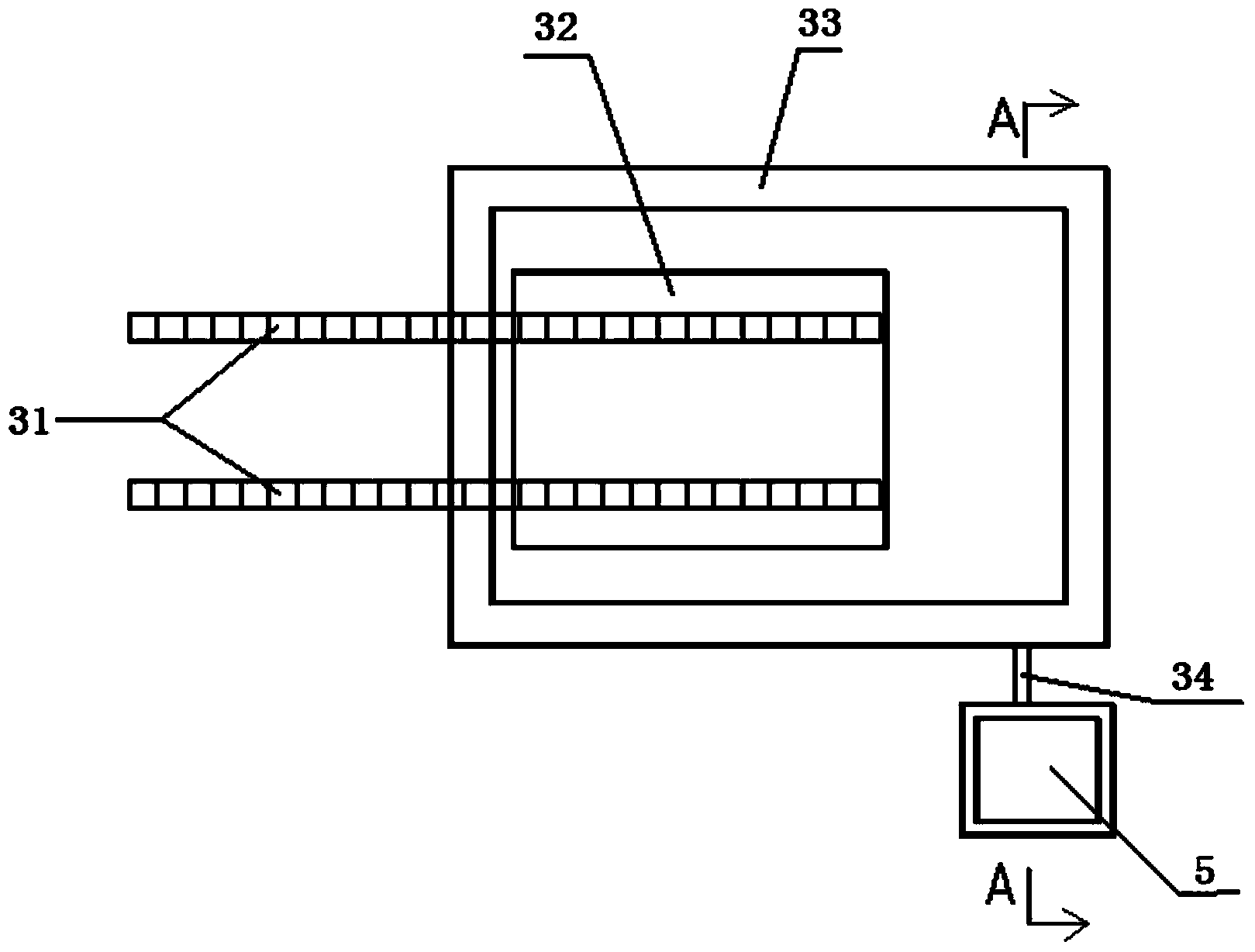

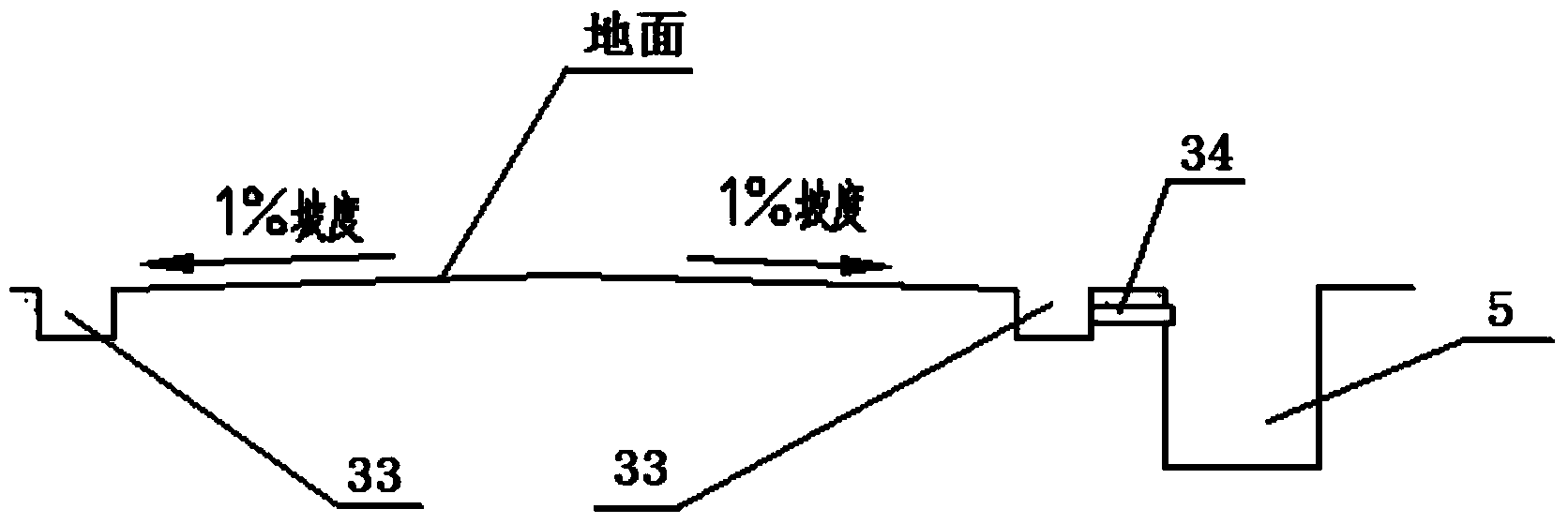

[0041] reference binding figure 1 , figure 2 , image 3 , in the automobile sheet metal stamping die cleaning system, the automobile sheet metal stamping die 1 to be washed enters and exits the cleaning chamber 2 through the automatic door 11 of the cleaning chamber 2 under the load of the carrying mechanism 3, and after completing the entry and exit, the automatic door 11 automatically Closing makes the cleaning chamber 2 a relatively closed space. A spraying device 4 is provided inside the cleaning chamber 2 , such as a spray gun, for spraying high-pressure cleaning fluid to the mold 1 to be cleaned. The cleaning solution is generally a fluid such as water with a cleaning agent added. Depend on figure 2 It can be seen that the carrying mechanism 3 includes a track 31 and a carrying platform 32. The automobile sheet metal stamping die 1 to be washed is placed on the carrying platform 32 and runs on the track 31. Of course, those of ordinary skill in the art can imagine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com