Plesoelectric ultrasonic flow sensor

A flow sensor, ultrasonic technology, applied in the field of sensors, to solve the problem of performance stability, improve the vibration state, and facilitate the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

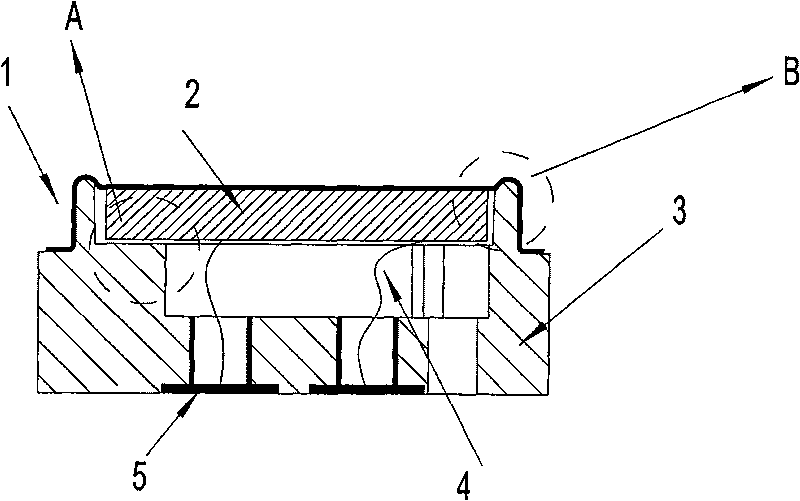

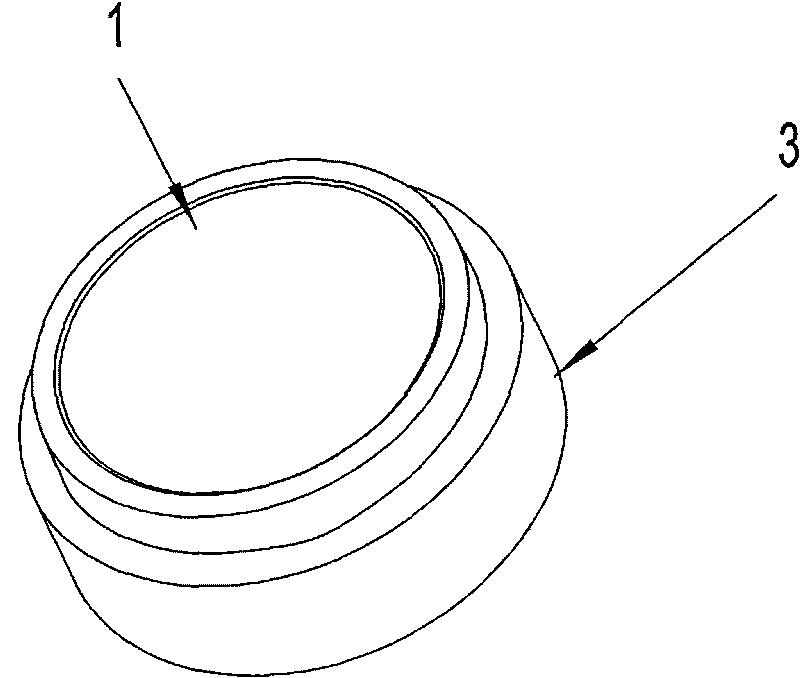

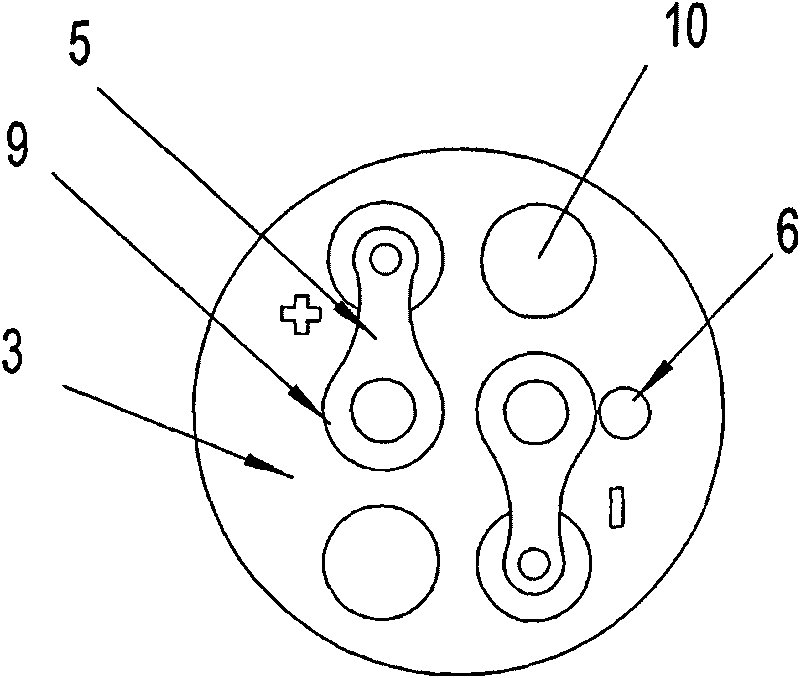

[0018] as attached figure 1 , attached figure 2 , attached image 3 As shown, the piezoelectric ultrasonic flow sensor of the present invention is composed of a metal shell 1, a sensor chip 2, a base 3, a connecting wire 4, and a welding piece 5. The sensor chip is arranged on the metal shell, and the metal shell is installed on the base. The welding piece is installed on the base, and the connecting wire connects the sensor chip and the welding piece. There is an arc-shaped buffer section on the end face of the metal shell, which is bent on the outer edge of the metal shell. The edge bending part is connected with the base, and the arc-shaped buffer section forms elasticity, which improves the deformation state of the end face of the metal shell under the liquid pressure. There are vent holes 6 on the base, which can maintain the balance of the internal and external air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com