Double juncture type independent spiral spring row in bags

A coil spring and bagging technology, applied in the field of spring arrays, can solve the problems of limited use range, bending of spring arrays, affecting the quality of cushions, etc., and achieve the effects of simple and reasonable structure, preventing elongation and deformation, and expanding the scope of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with accompanying drawing (embodiment):

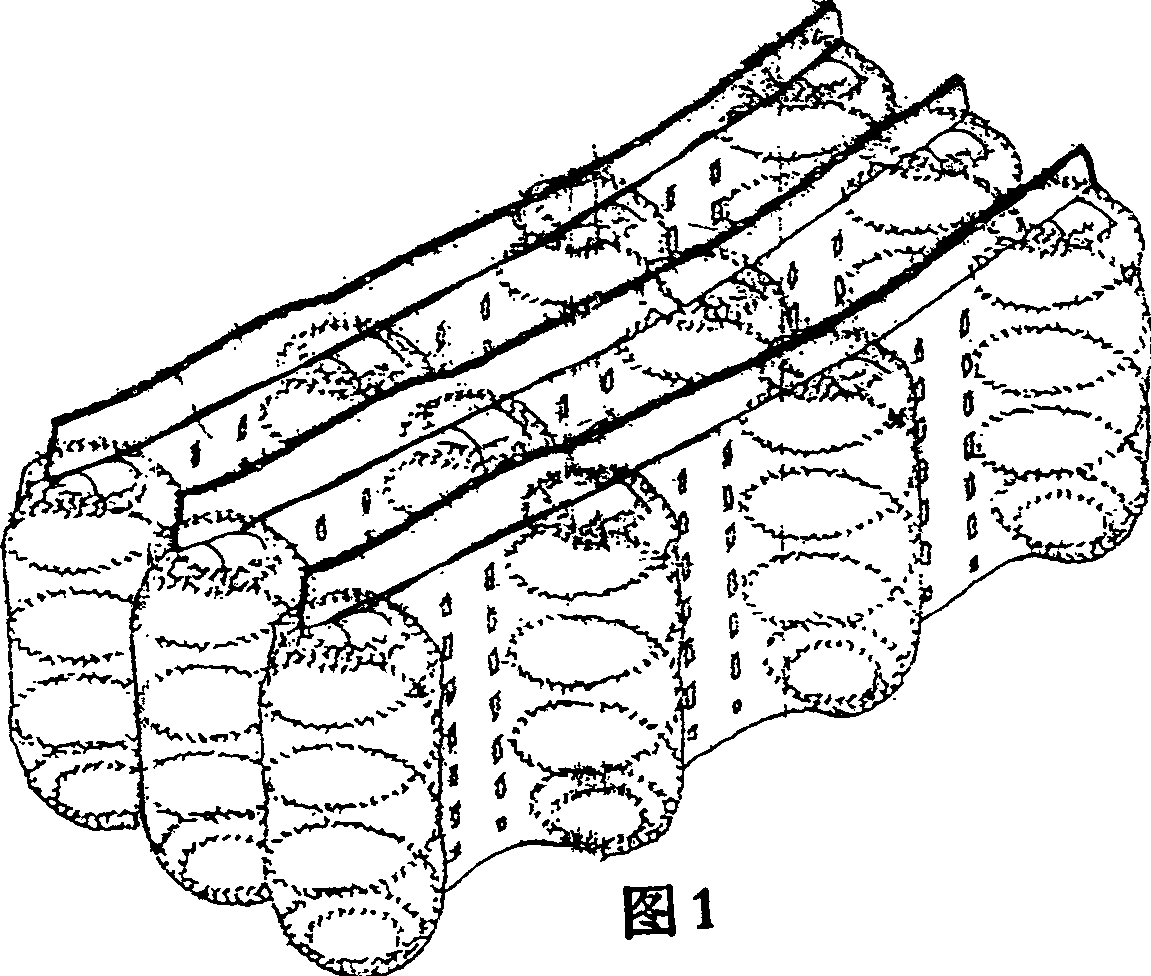

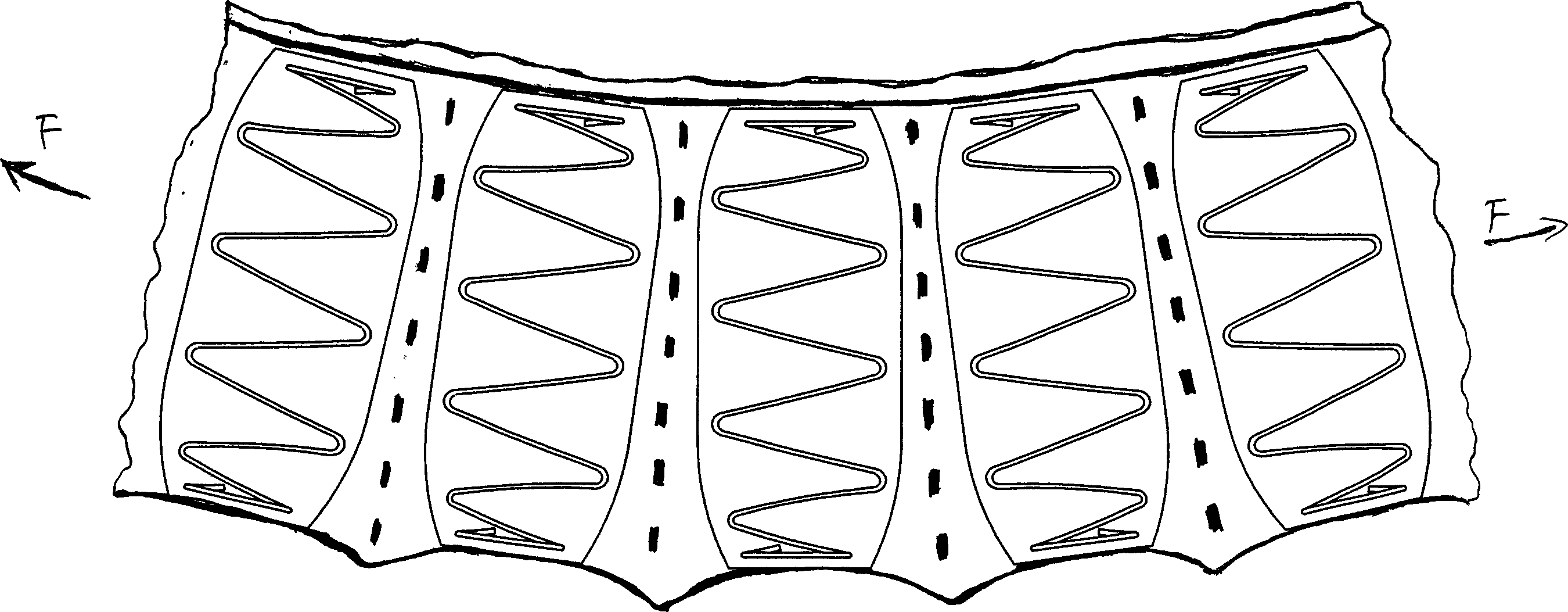

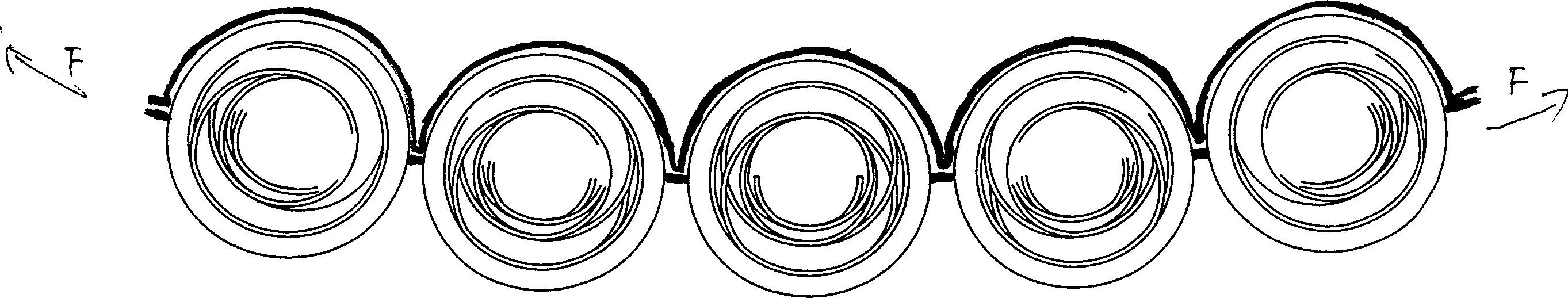

[0015] refer to Figure 4 , The present invention includes a bag body 1 and a coil spring 2 . Each helical spring 2 is arranged side by side to form a helical spring row, and the bag body 1 is divided into two pieces of cloth, wrapped outside it, and forms two longitudinal seams 3, 4 consistent with the row direction, two seams 3, 4 are respectively located on the plane where the two ports of the cylinder of the coil spring 2 are located. Seams 3 and 4 can be welded, welded, sewn, glued and other processes. Due to the addition of a seam, the elongation and deformation of the spring row under the tension in the row direction can be effectively prevented; and because the two seams 3 and 4 are symmetrical structures, it can improve the spring row after being stressed in the row direction. In the deformed state, even if the force in the column directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com