Method for carrying out CAE analysis on rigidity of auxiliary frame of special vehicle

A sub-frame and special-purpose vehicle technology is applied in the field of CAE analysis of the sub-frame stiffness of special-purpose vehicles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

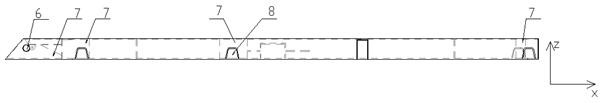

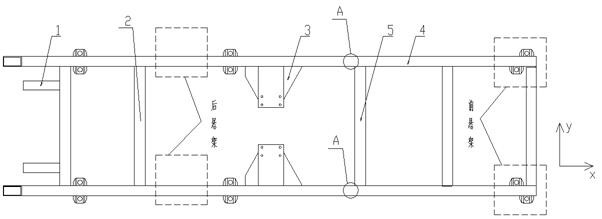

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] Such as figure 1 with figure 2 , the present invention is a method for performing CAE analysis on the stiffness of the subframe of a special purpose vehicle. Curved beam 5, cylindrical tube 6, reinforcing plate 7 and connecting fixed bracket 8, main girder 4 is used for installing front suspension and rear suspension, the present invention comprises to the CAE analysis method of special vehicle auxiliary frame:

[0028] 1) Establish the CAE analysis model of the subframe:

[0029] Firstly, the geometry of the 3D model of the sub-frame of the special vehicle is cleaned up, and then the grid is divided to establish the analysis model of each part on the sub-frame;

[0030] 2) Apply the constraints and loads required for bending stiffness calculation:

[0031] The two main beams 4 in the subframe are located at the installation positions of the leaf springs of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com