Thermal barrier coating thermal shock simulation testing device and testing method

A simulation test, thermal barrier coating technology, applied in the direction of measuring device, testing wear resistance, testing material strength by applying repetitive force/pulsation force, etc., can solve coating failure, coating peeling off, real thermal vibration of coating Misjudgment of life and other problems, to reduce the possibility, improve accuracy, and improve uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

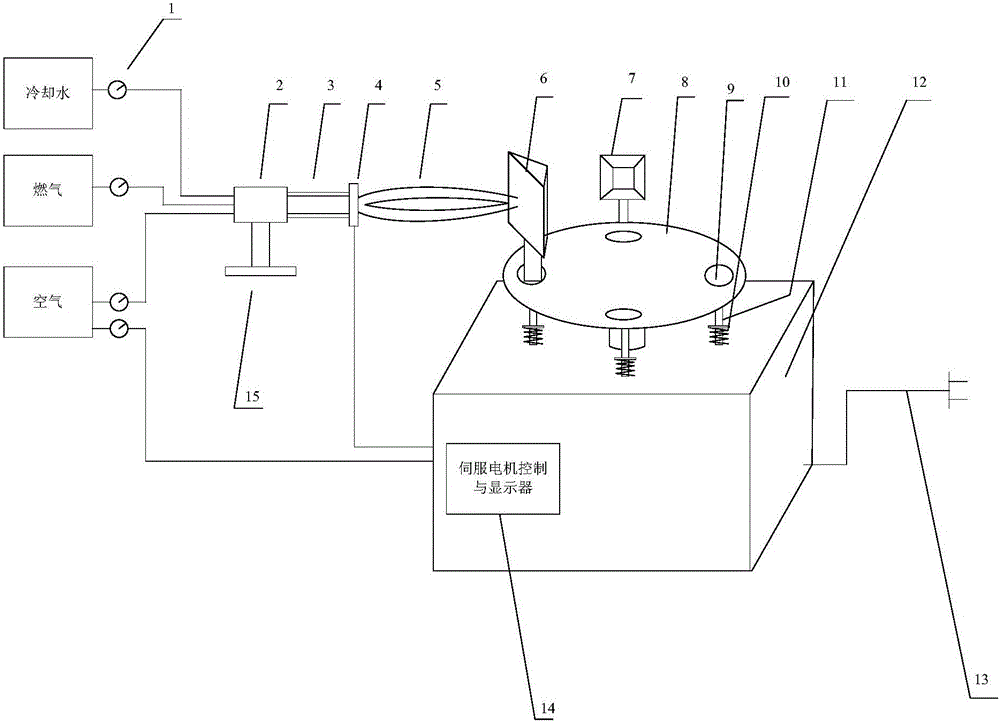

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

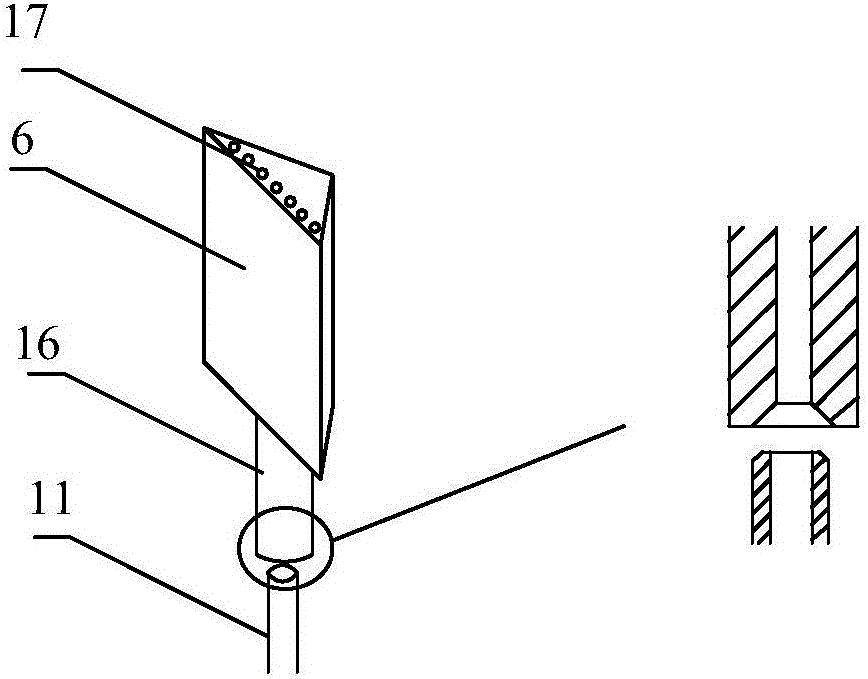

[0019] Such as figure 1 and figure 2 As shown, the installation and use process of the device of the present invention is as follows: firstly, the gas circuit and the cooling water pipeline are connected with the combustion chamber 2, and a heat-resistant steel nozzle 3 with a throat diameter of 15 mm, an expansion angle of 10° and a length of 25 mm is used. Insert it into the combustion chamber 2, and install the igniter 4 on the front end of the nozzle 3 through threaded connection, and install the above-mentioned connected combustion system on the burner support 15. Connect the 100mm×100mm plate-shaped nickel-based alloy substrate 6 with the cooling air bag 17 of the same size to form a hollow structure, and then spray thermal barrier coating on the plate-shaped nickel-based alloy substrate 6, after the spraying is completed, it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com