Coated white board paper

A white board paper and coating technology, which is applied in coating, paper, papermaking, etc., can solve the problems that white spots cannot be eliminated, the coating amount changes, and the production cost becomes higher, so as to improve the appearance of white spots, less possibility, and improve the appearance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

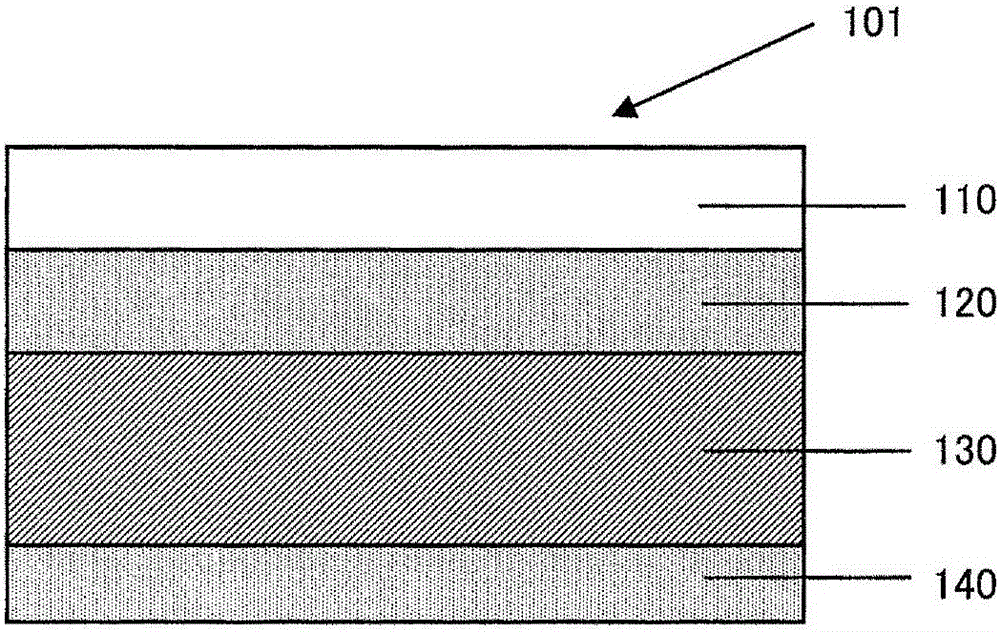

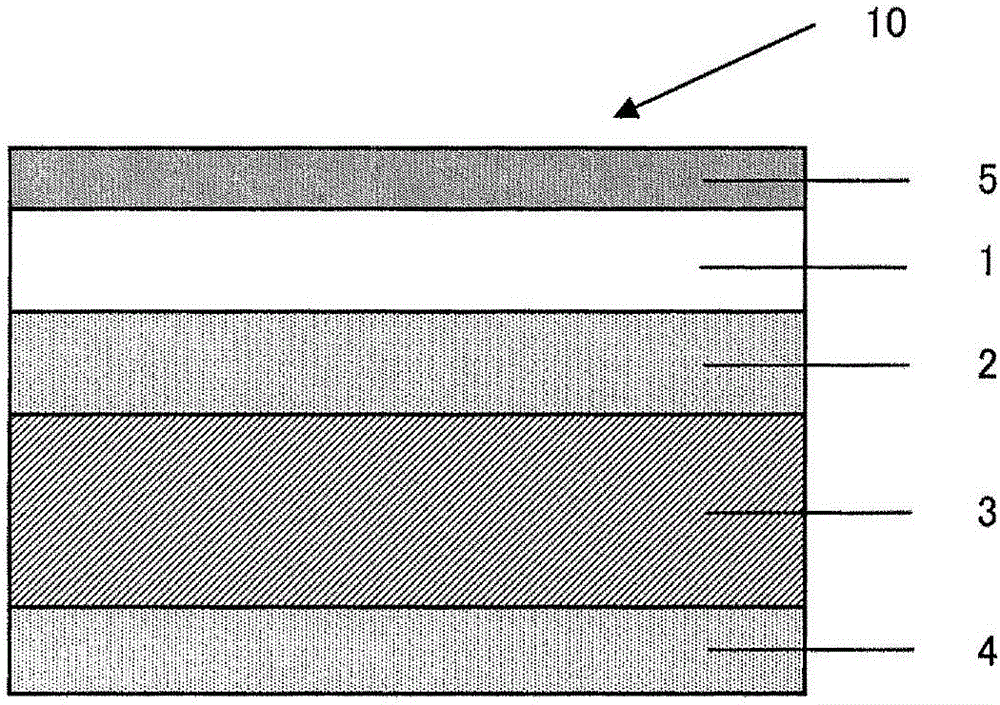

Method used

Image

Examples

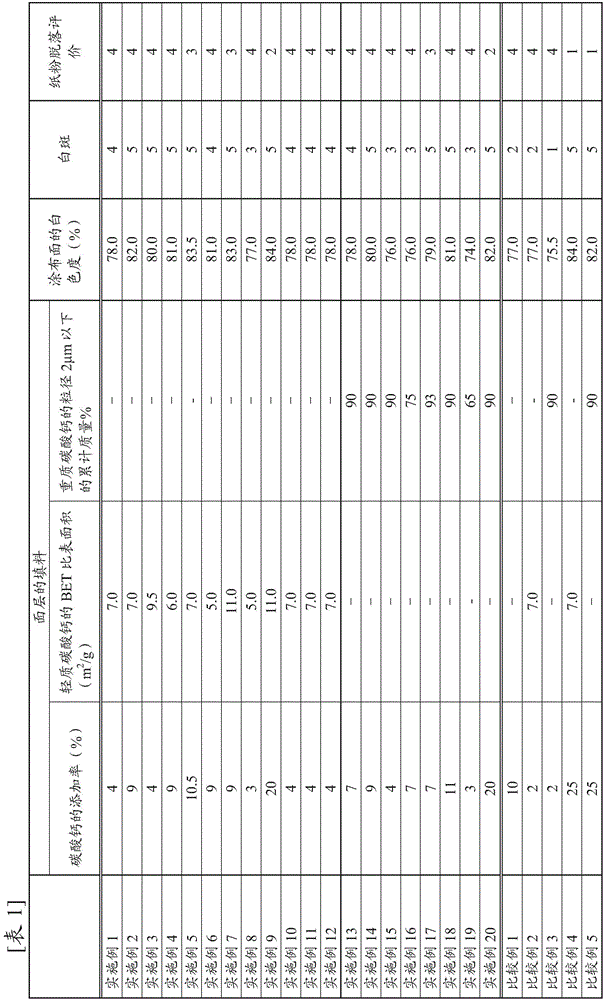

Embodiment 1

[0053] Disperse 90 parts of hardwood pulp (L-BKP) and 10 parts of softwood pulp (N-BKP) in water, adjust to 350 cc of CSF to obtain flow pulp, and mix light carbonate with a content of 4% relative to the pulp amount into the flow slurry Calcium (trade name: TP121-6S / Okutama Industry Co., Ltd. BET specific surface area 7.0m 2 / g) obtain the raw material of surface layer. Then disperse the unbeaten deinked bleached waste paper pulp in water to obtain the raw materials of the lining layer and the bottom layer. The deinked waste magazine pulp was then dispersed in water to obtain the raw material for the core layer. Using fourdrinier paper machine under the condition of pH7.7, using various raw materials to make 4 layers of surface layer / lining layer / core layer / bottom layer, the weight per square meter is 310g / m 2 white paper. The weight per square meter of the surface layer of the obtained white board paper is 25g / m 2 , the whiteness is 78%; the weight per square meter of th...

Embodiment 2

[0055] Light calcium carbonate (trade name: TP121-6S / Okutama Industry Co., Ltd. BET specific surface area 7.0m 2 / g) was added to 9% relative to the amount of pulp, and papermaking was carried out in the same manner as in Example 1 to obtain coated white board paper.

Embodiment 3

[0057] Change the calcium carbonate mixed in the surface layer of white board paper to light calcium carbonate (the specific surface area of the trial product ABET is 9.5m 2 / g), in addition, by the same method papermaking of embodiment 1, obtain coated white board paper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com