Marine engineering concrete with abrasion resistance and chlorine salt corrosion resistance

A technology of anti-abrasion and concrete, which is applied in the field of building materials, can solve the problems of lack of anti-chloride ion permeability and collaborative design of anti-abrasion performance, and achieve excellent anti-abrasion performance and anti-chloride ion penetration performance, preparation process Simple and convenient, simple source effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

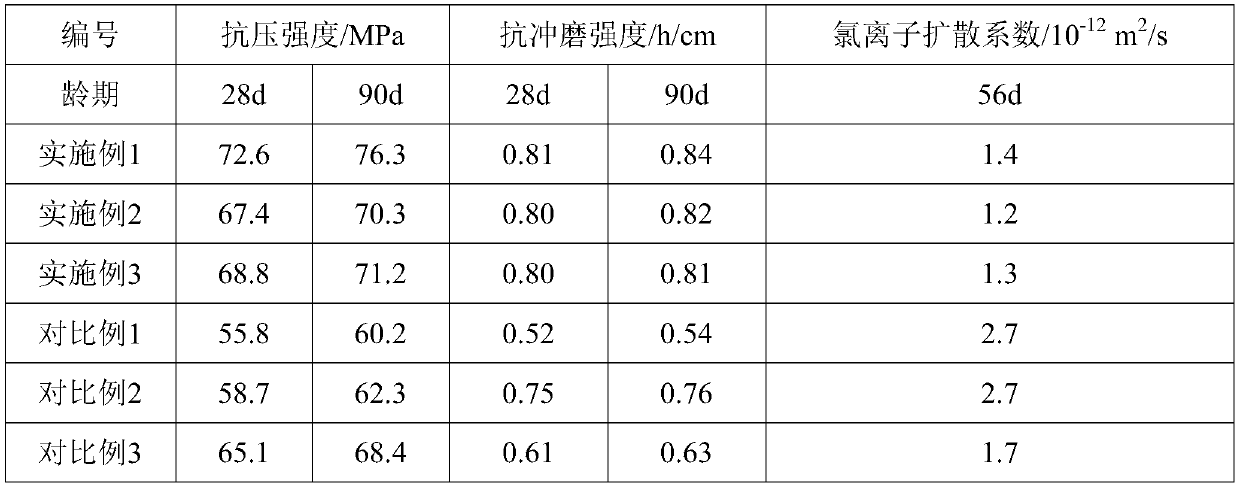

Examples

Embodiment 1

[0029] A marine anti-abrasion and chlorine-salt corrosion-resistant concrete, and its preparation method includes the following steps:

[0030] 1) Weigh the raw materials according to the ratio, and the raw materials and their dosage are: P.O42.5 cement 240kg / m 3 , Superfine mineral powder 100kg / m 3 , Ceramic powder 60kg / m 3 , Granite gravel 1150kg / m 3 , River sand 740kg / m 3 , Polycarboxylic acid superplasticizer 10kg / m 3 , Water 132kg / m 3 ;

[0031] 2) After the weighed P.O42.5 cement, superfine mineral powder, ceramic powder, granite crushed stone and river sand are mixed evenly, add polycarboxylic acid superplasticizer and water, and stir fully to obtain the Marine engineering anti-abrasion and chlorine salt corrosion resistant concrete.

Embodiment 2

[0033] A marine anti-abrasion and chlorine-salt corrosion-resistant concrete, and its preparation method includes the following steps:

[0034] 1) Weigh the raw materials according to the proportion, and the raw materials and their dosage are: P.O42.5 cement 210kg / m 3 , Superfine mineral powder 110kg / m 3 , Ceramic powder 70kg / m 3 , Granite gravel 1150kg / m 3 , River sand 785kg / m 3 , Polycarboxylic acid superplasticizer 11kg / m 3 , Water 124kg / m 3 ;

[0035] 2) After the weighed P.O42.5 cement, superfine mineral powder, ceramic powder, granite crushed stone and river sand are mixed evenly, add polycarboxylic acid superplasticizer and water, and stir fully to obtain the Marine engineering anti-abrasion and chlorine salt corrosion resistant concrete.

Embodiment 3

[0037] A marine anti-abrasion and chlorine-salt corrosion-resistant concrete, and its preparation method includes the following steps:

[0038] 1) Weigh the raw materials according to the ratio, and the raw materials and their dosage are: P.II 42.5 cement 200kg / m 3 , Superfine mineral powder 120kg / m 3 , Ceramic powder 70kg / m 3 , Basalt gravel 1180kg / m 3 , River sand 770kg / m 3 , Polycarboxylic acid superplasticizer 10kg / m 3 , Water 125kg / m 3 ;

[0039] 2) After the weighed P.II 42.5 cement, ultra-fine mineral powder, ceramic powder, basalt crushed stone, and river sand are mixed evenly, add polycarboxylic acid superplasticizer and water, and stir thoroughly to obtain the sea The concrete is resistant to erosion and corrosion by chlorine salt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com