Wet-mixing plastering mortar and preparation method thereof

A plastering mortar and wet mixing technology, which is applied in the field of building materials, can solve the problems of mortar falling off, mortar bonding is not firm, etc., to achieve the effect of improving the degree of adhesion, reducing the possibility, and improving the adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

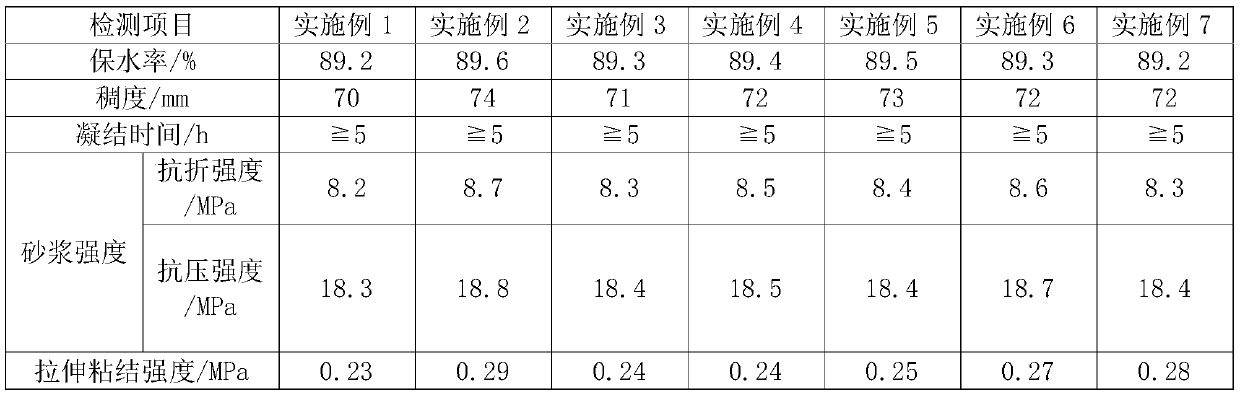

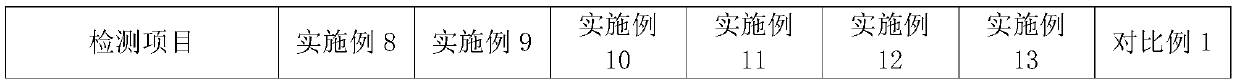

Examples

Embodiment 1

[0035] A method for preparing wet-board plastering mortar includes the following steps:

[0036] S1: Preparation of additives: In terms of parts by weight, 5 parts of hydroxyethyl cellulose ether, 3 parts of wood fiber, and 2 parts of vitrified microbeads are mixed uniformly to prepare additives for use;

[0037] S2: Preparation of bonding components: In terms of parts by weight, soak the jute fiber in a 2% NaOH solution for 10 minutes, then take it out and wash it with distilled water, dry it at 80°C, and then treat it. 1 part of jute fiber, 2 parts of epoxy resin, 2 parts of carboxyl styrene-butadiene latex, and 2 parts of polyvinyl alcohol are mixed uniformly to obtain a bonding component for use;

[0038] S3: Preparation of wet-mix plastering mortar: mix 140 parts of cement and 750 parts of fine aggregate and grind for 10 minutes, add 130 parts of water and stir, then add 6 parts of additives, 3 parts of bonding component and mix them evenly; The materials include 200 parts of n...

Embodiment 2

[0040] A method for preparing wet-board plastering mortar includes the following steps:

[0041] S1: Preparation of additives: In terms of parts by weight, 9 parts of hydroxyethyl cellulose ether, 5 parts of wood fiber, and 5 parts of vitrified microbeads are mixed uniformly to prepare additives for use;

[0042] S2: Preparation of bonding components: In terms of parts by weight, soak the jute fiber in 4% NaOH solution for 12 minutes, then take it out and wash it with distilled water, dry it at 90°C, and then treat it 3.5 parts of jute fiber, 5 parts of epoxy resin, 3 parts of carboxyl styrene butadiene latex, and 4 parts of polyvinyl alcohol are mixed uniformly to obtain a bonding component for use;

[0043] S3: Preparation of wet-mix plastering mortar: mix 180 parts of cement and 810 parts of fine aggregate and grind for 15 minutes, add 142 parts of water and stir, then add 10 parts of additives and 6.5 parts of binding component and mix well; fine aggregate Including 270 parts of...

Embodiment 3

[0045] A method for preparing wet-board plastering mortar includes the following steps:

[0046] S1: Preparation of additives: In terms of parts by weight, 12 parts of hydroxyethyl cellulose ether, 7 parts of wood fiber, and 8 parts of vitrified microbeads are mixed uniformly to prepare additives for use;

[0047] S2: Preparation of bonding components: In terms of parts by weight, soak the jute fiber in a 6% NaOH solution for 15 minutes, then take it out and wash it with distilled water, dry it at 100°C, and then treat it 5 parts of jute fiber, 8 parts of epoxy resin, 4 parts of carboxyl styrene-butadiene latex, and 6 parts of polyvinyl alcohol are mixed uniformly to obtain a bonding component for use;

[0048] S3: Preparation of wet-mix plastering mortar: mix 220 parts of cement and 880 parts of fine aggregate and grind for 20 minutes, add 154 parts of water and stir, then add 14 parts of additives and 9 parts of binding components and mix them evenly; fine aggregate Including 270 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com