Automatic production device for cleaning, drying and painting zipper head

A technology for production equipment and zipper pullers, which is applied in the direction of surface coating liquid equipment, spraying equipment, spray booths, etc., can solve the problems of high labor intensity and low production efficiency for workers, and achieve reduction of work load, increase of temperature, increase of The effect of rotational stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

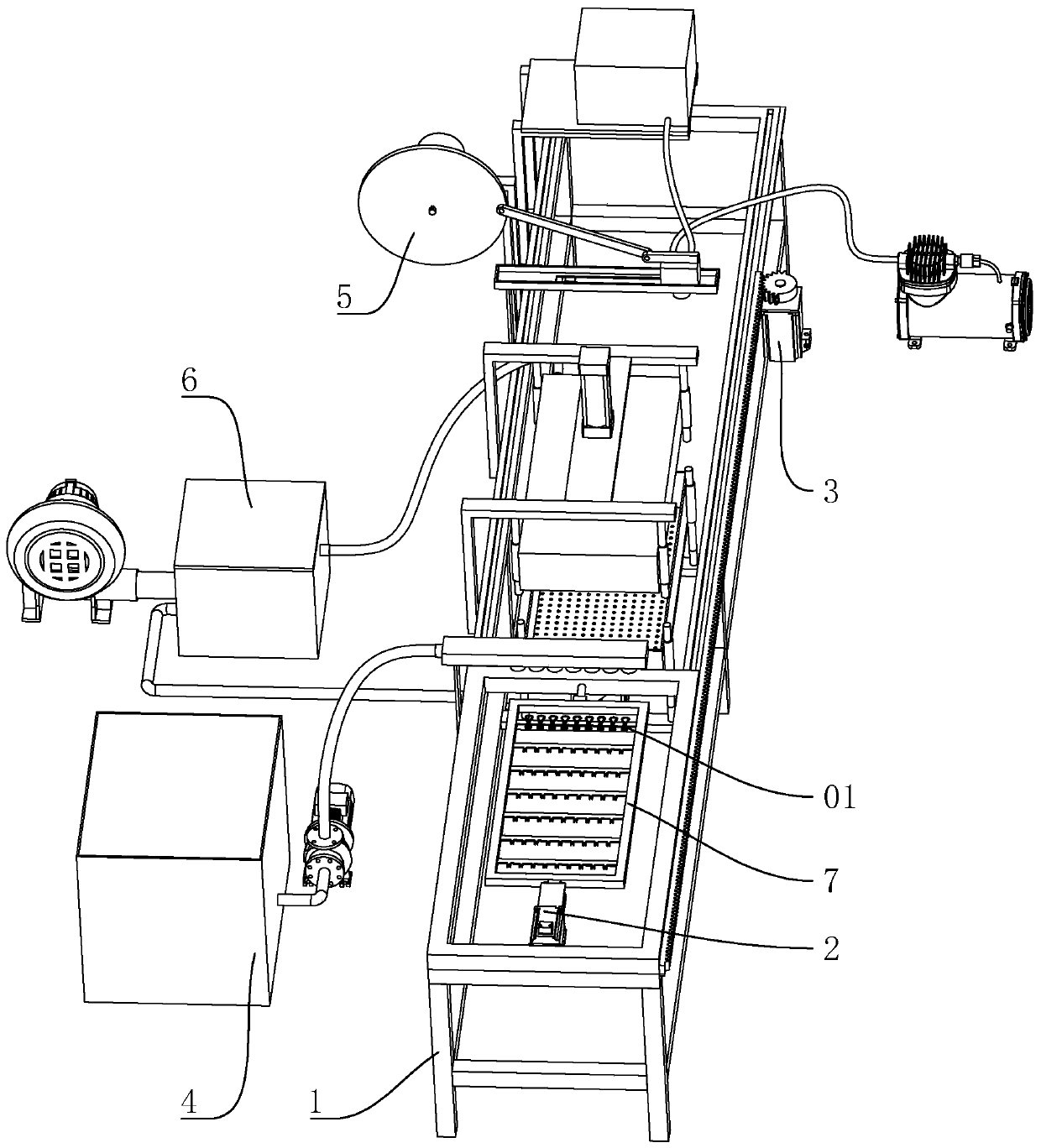

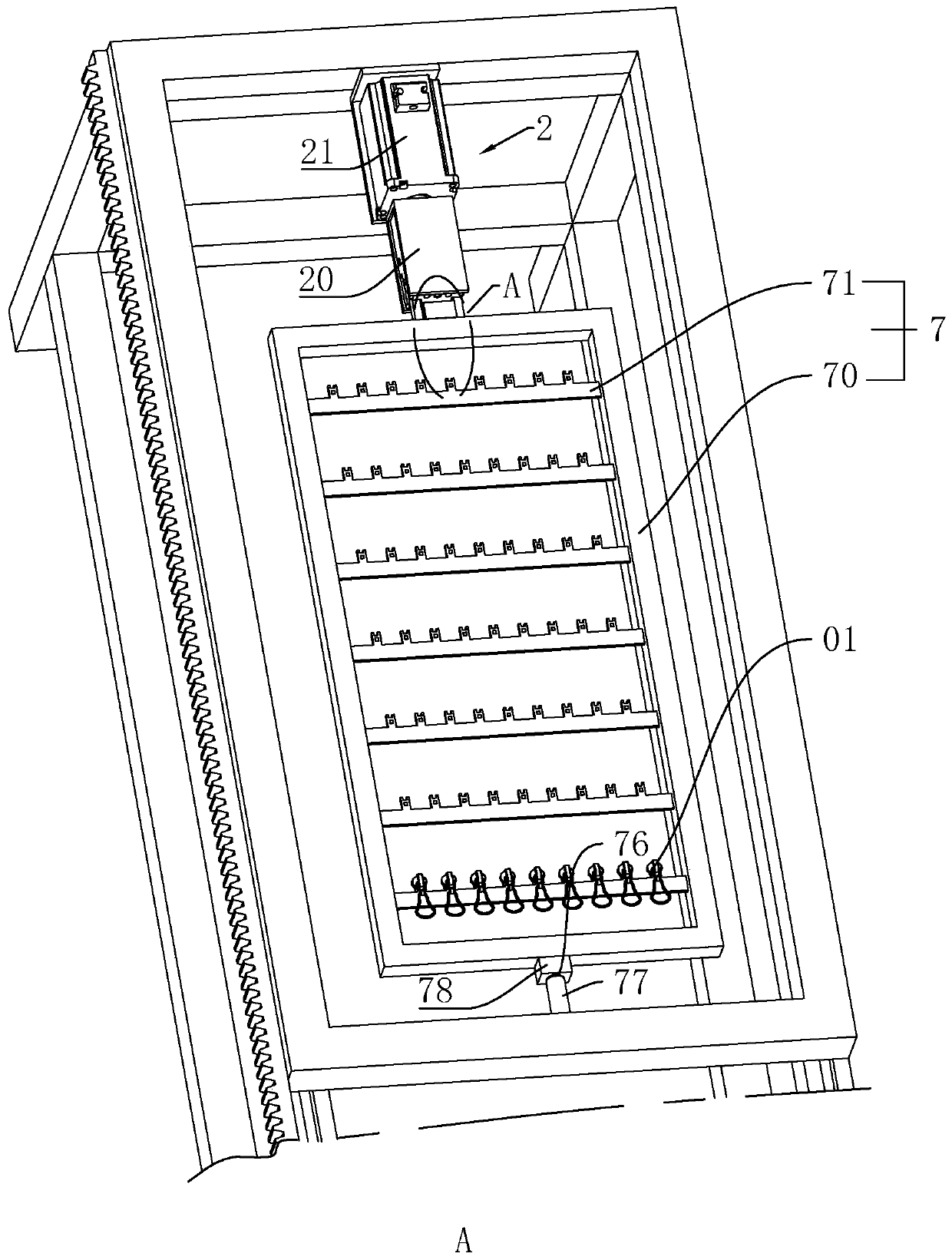

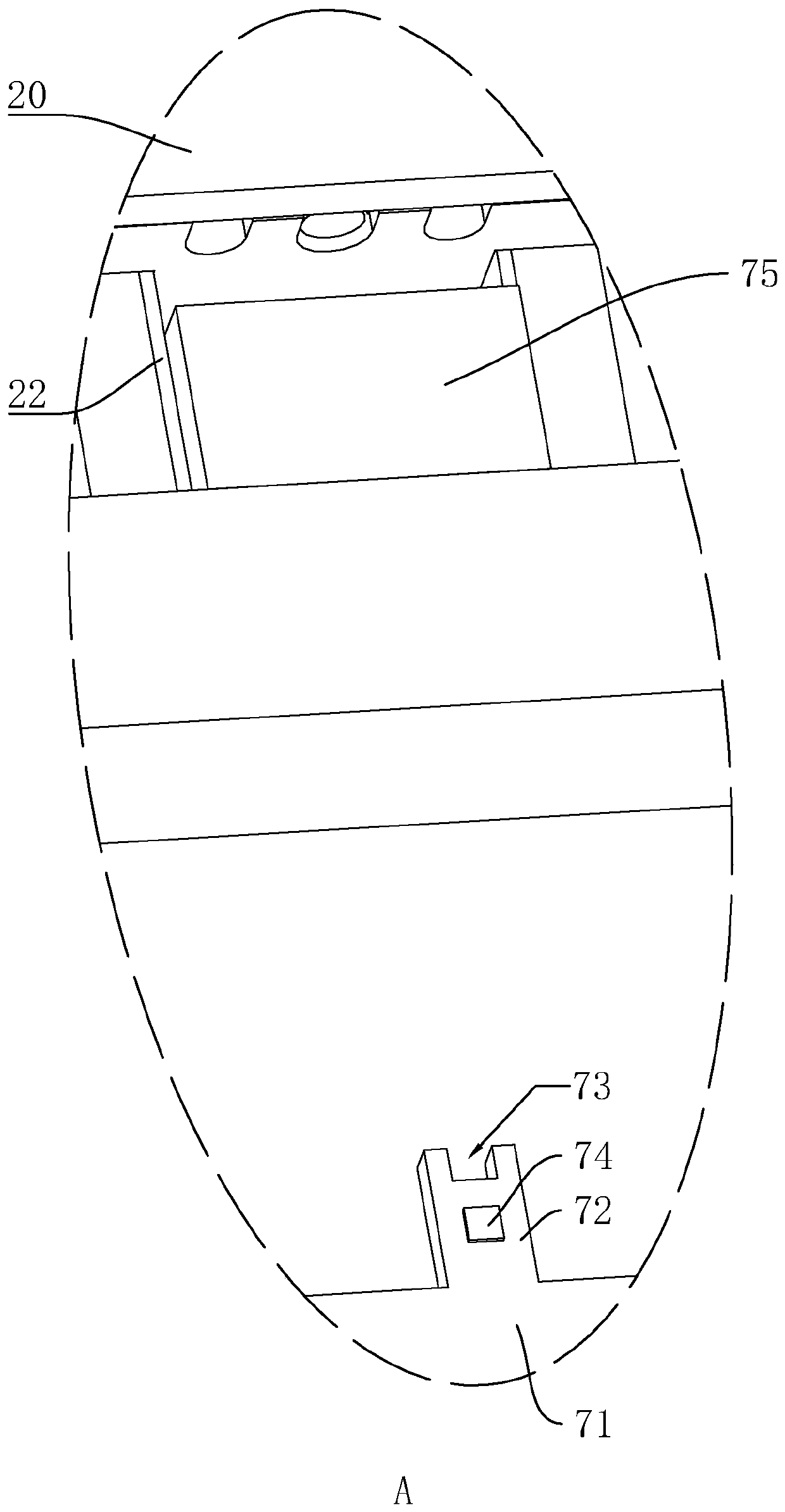

[0046] refer to figure 1 , an automatic production device for cleaning, drying, and spraying zipper pulls, which includes a frame 1, on which are respectively provided rotating assemblies 2 for fixing and rotating the zipper pull 01, and for driving the rotating assemblies 2 to move intermittently The moving assembly 3 for the zipper puller 01 is cleaned, the spraying assembly 5 for spraying the zipper puller 01 is used, and the baking assembly 6 is used for drying the zipper puller 01. The frame 1 is provided with a Fix the hanger 7 of the zipper puller 01, the hanger 7 is fixed on the rotating assembly 2, the washing assembly 4 and the spraying assembly 5 are respectively located on both sides of the baking assembly 6; when the zipper puller 01 is processed, the hanger 7 is installed On the rotating assembly 2, use the moving assembly 3 to drive the rotating assembly 2 to move. When it moves to the flushing assembly 4, the flushing assembly 4 rinses the zipper head 01 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com