Polishing pad and preparation method and application thereof

A polishing pad and polishing layer technology, which is applied in the direction of grinding/polishing equipment, manufacturing tools, metal processing equipment, etc., can solve the defects of polishing layer adaptability, different degrees of wafer surface grinding, and difficulty in controlling the flatness of wafer grinding issues with uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

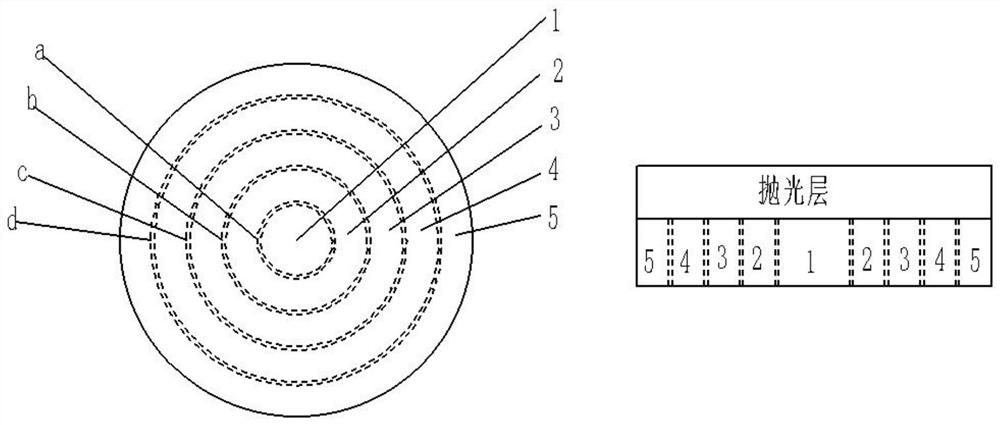

[0056] Preparation of polishing layer:

[0057] The raw material of polishing layer comprises each component of following mass fraction: the prepolymer of 100 parts of isocyanate termination, the curing agent of 20 parts and the hollow microsphere of 2.0 parts; Wherein, the prepolymer of described isocyanate termination is made of toluene di It is obtained by reacting isocyanate and polytetrahydrofuran; the curing agent is MOCA, and the MOCA is 3,3-dichloro-4,4-diaminodiphenylmethane; the model of the hollow microsphere is 551DE20d42.

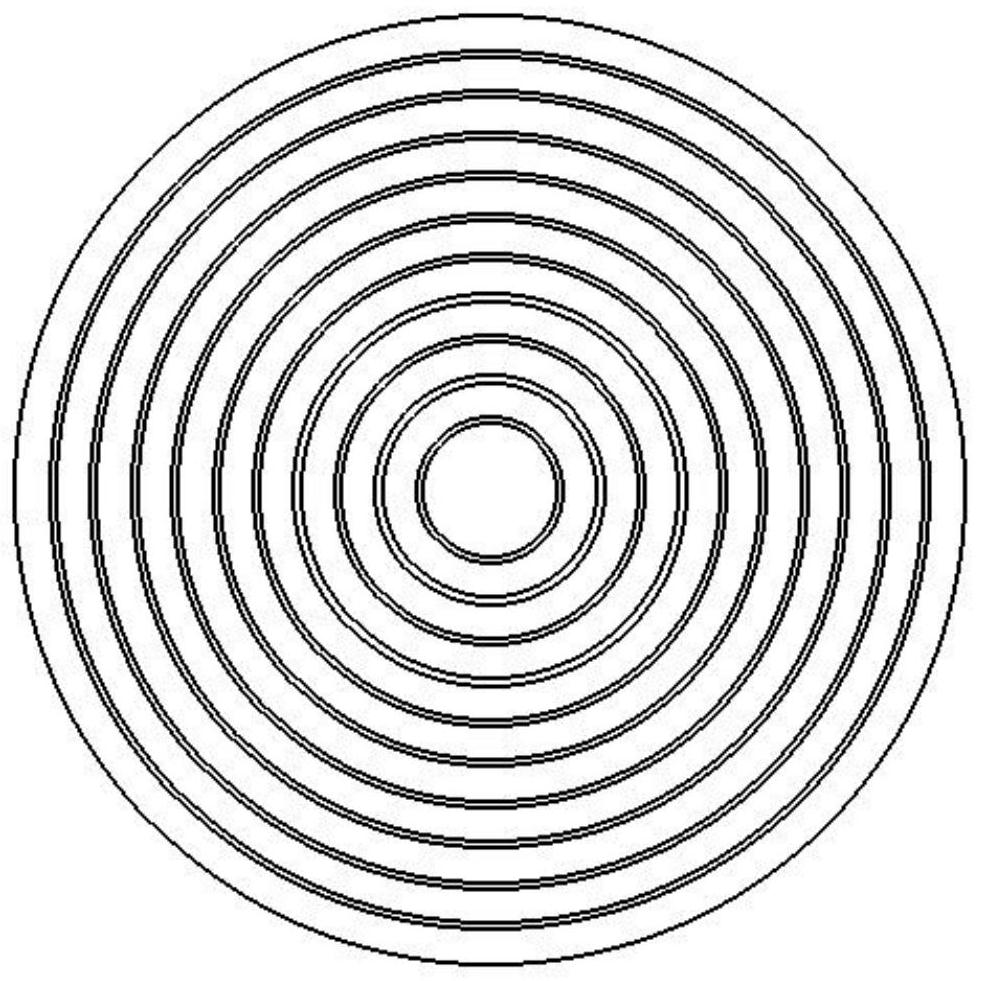

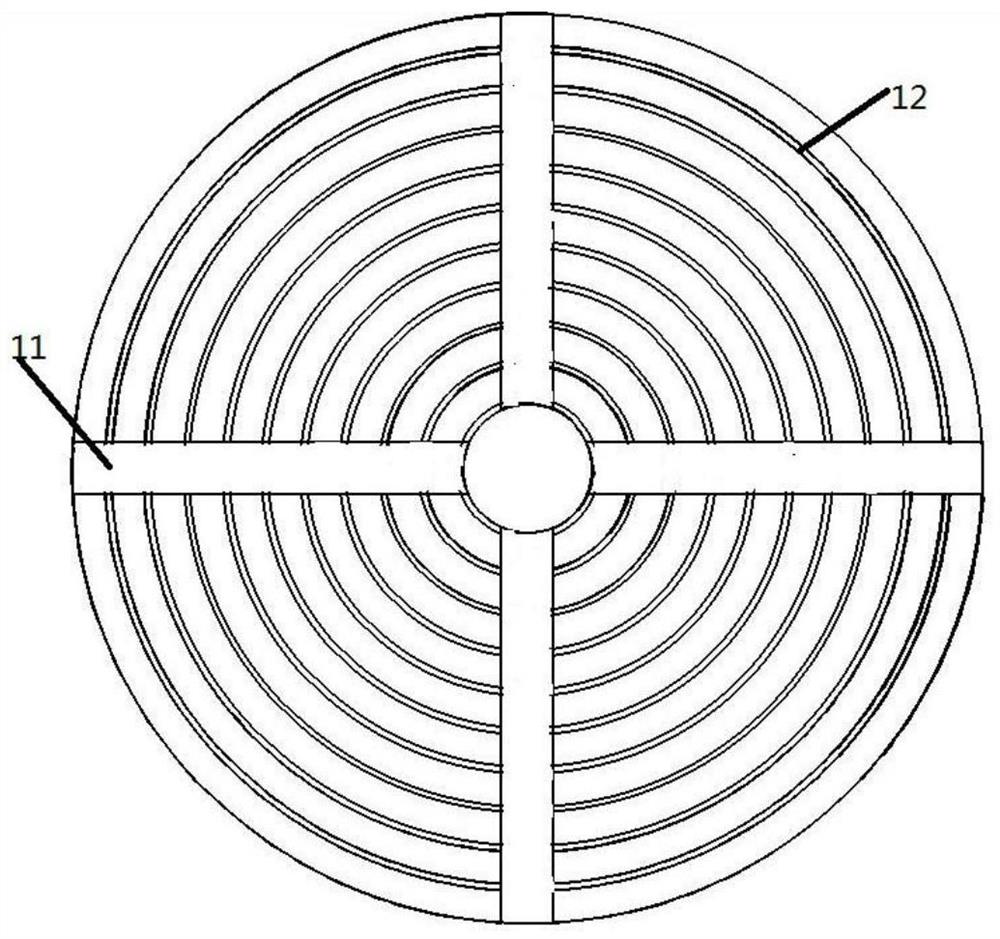

[0058] In the present invention, preferably, radial grooves are further provided on the polishing layer, and the radial grooves are used to receive polishing fluid during polishing. Wherein, the width of the radial groove is preferably 0.1-0.6 cm, more preferably 0.2-0.4 cm.

[0059] Specific steps:

[0060] Step (1): the treatment of the isocyanate-terminated polyurethane prepolymer (or prepolymer for short); the specific operations are as f...

Embodiment 1-10

[0065] Step (1): 100 parts of prepolymer with NCO% content of 7.74%-9.45%, 16.7 parts of BDO, 50 parts of DMF solution, after mixing evenly, react at 80°C for 200min to obtain the required polyurethane solution.

[0066] Step (2): Make the density 0.10-0.30g / cm 3 The impregnated viscosity of the polyester non-woven fabric is 6000-15000cp in the DMF (dimethylformamide) solution of polyurethane for 100-300s. Generally speaking, the density of the buffer layer can be adjusted by the density of the non-woven fabric and the viscosity of the polyurethane DMF solution. Polyurethane DMF solution is easier to impregnate low-density non-woven fabrics to form high-density cushions: after immersion in the coagulation tank of 5% DMF aqueous solution for 300s to shape TPU; after immersion in water washing tank for 200s, the large Part of the DMF solution was washed off; and then placed in a tunnel furnace at 150°C for 600s to remove water and DMF solution.

[0067] Step (3): The buffer pad i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com