Chemical mechanical polishing solution

A technology of chemical mechanics and polishing liquid, which is applied in other chemical processes, chemical instruments and methods, polishing compositions containing abrasives, etc., can solve the problems that the polishing rate and planarization efficiency of dielectric materials cannot be taken into account at the same time, and achieve extended Effects of polishing time, high planarization efficiency, and simplified steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

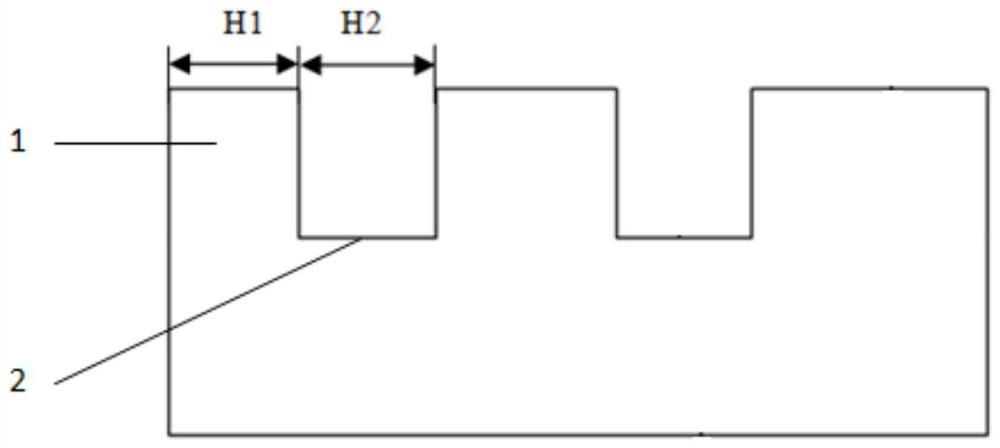

Image

Examples

Embodiment 3

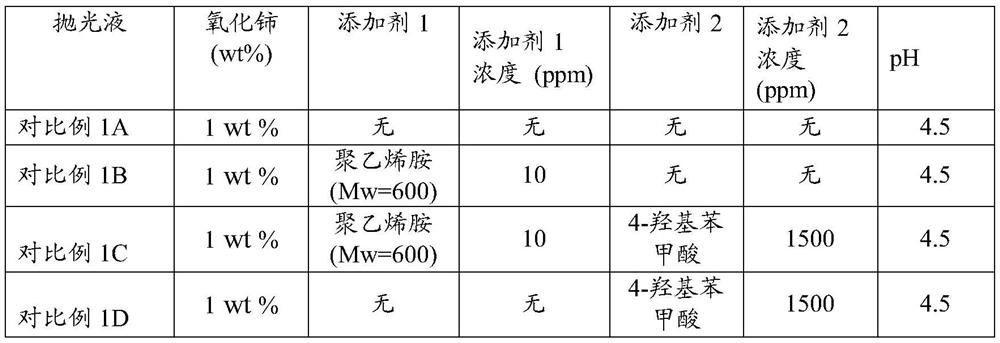

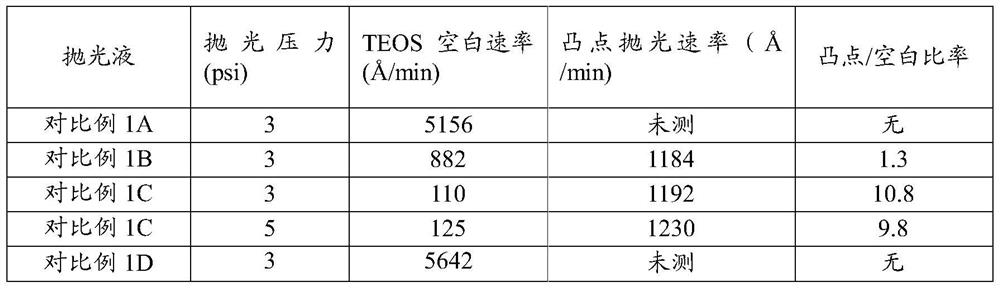

[0045] Preparation method: in this embodiment, the reference example contains 1.2wt% sol-type cerium oxide, and other embodiments and comparative examples then add a certain amount of compound (see Table 5) on the basis of the reference example, and use ammonia water (NH 4 OH) or nitric acid (HNO3) to adjust the pH to 4.5.

[0046] Polishing method: Mirra polishing machine is used to perform polishing test on patterned wafer. The corresponding polishing conditions include: IC1010 polishing pad, the speed of polishing disc (Platten) and polishing head (Carrier) are 93rpm and 87rpm respectively, and the polishing liquid The flow rate was 150 mL / min and the polishing pressure was 5 psi. The TEOS film thickness was measured with a NanoSpec film thickness measurement system (NanoSpec6100-300, Shanghai Nanospec Technology Corporation). Starting at 3mm from the edge of the wafer, measure 49 points at equal intervals on the diameter line. The polishing rate is an average of 49 point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com