Polishing solution for TSV barrier layer

A technology of polishing liquid and barrier layer, applied in the field of polishing liquid, to achieve the effect of clear and sharp thin line area, good planarization efficiency and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

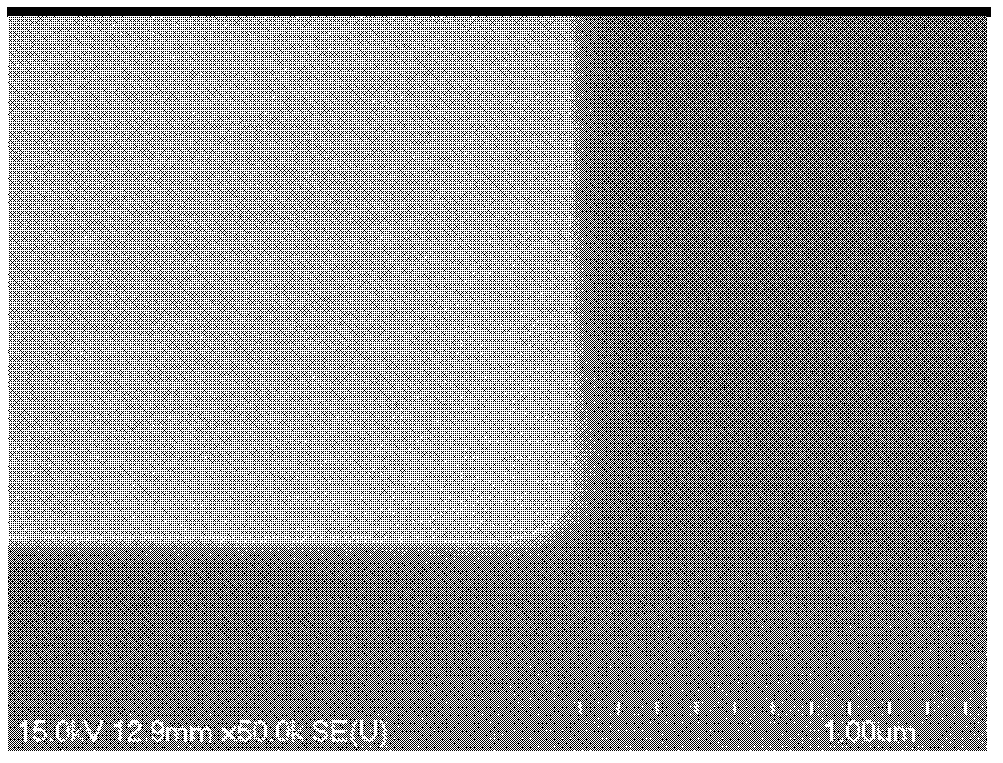

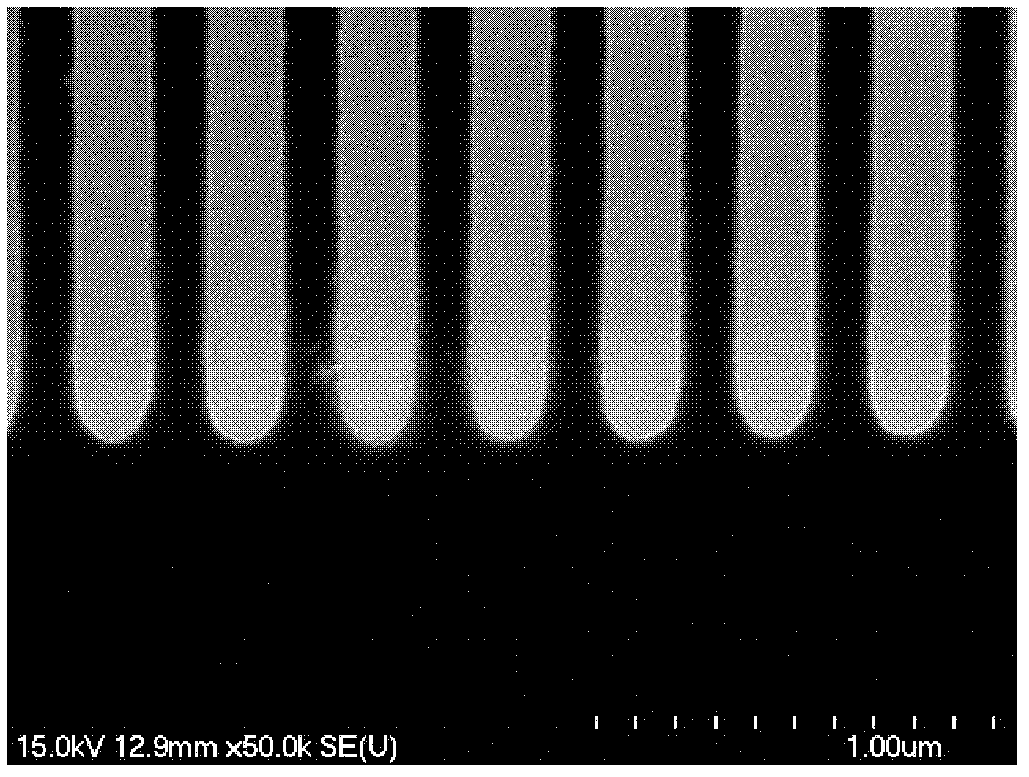

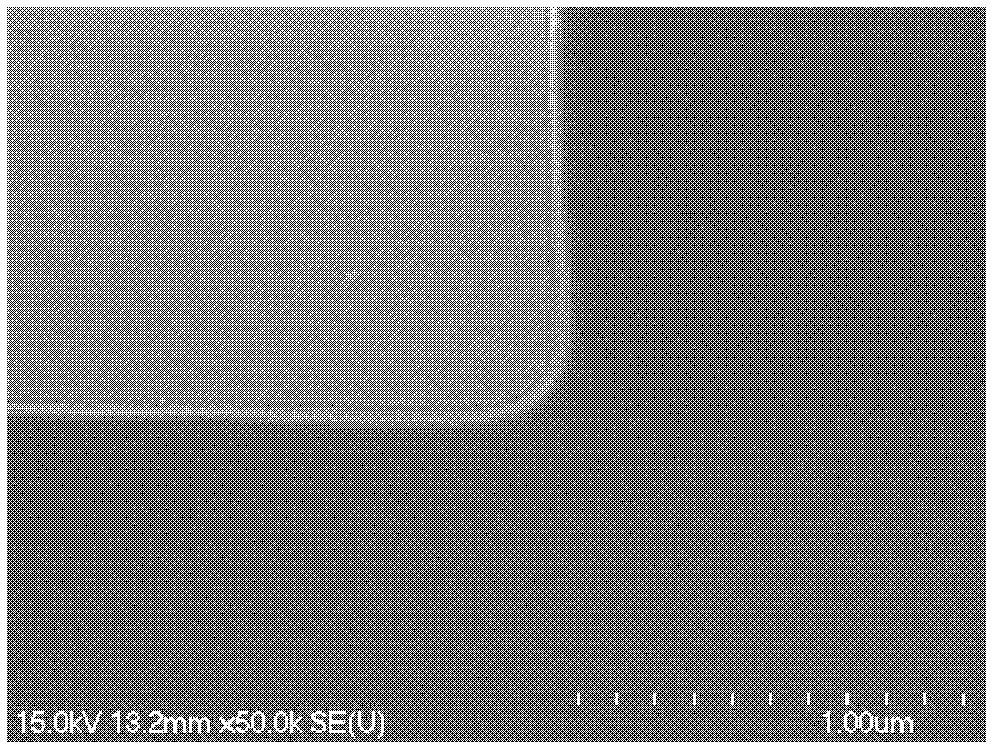

Image

Examples

Embodiment Construction

[0029] The advantages of the present invention will be further elaborated below through specific embodiments.

[0030] Polishing conditions:

[0031] Polishing pad: IC pad

[0032] Polishing conditions: 70 / 90rpm

[0033] Polishing fluid flow: 100ml / min

[0034] Static corrosion rate: Put the freshly polished copper sheet into the slurry and immerse it for 15 minutes, and measure the film thickness before and after.

[0035] Butterfly Depression: A Semitech 854 patterned wafer was used to measure the butterfly depression of an 80um metal block.

[0036] Polishing Uniformity Within Slice: Butterfly dips for different line widths within a die.

[0037] Blank Wafer: PETEOS, Ta, Cu, Si3N4

[0038] Table 1, the formula of embodiment 1-7 and contrast polishing liquid

[0039]

[0040]

[0041] BTA: benzotriazole, PAA: polyacrylic acid, PBTCA: 2-phosphonic acid-1,2,4-tricarboxylic butane. DISN1, disodium methylene bis-naphthalenesulfonate, DISN2: methylnaphthalenesulfonat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com