Integrated grinding pad and its mfg. method

The integrated structure of the elastic support layer and the polishing layer composed of chemically compatible materials solves the problems of low efficiency and complex manufacturing of existing polishing pads in the polishing process, achieves efficient planarization and real-time detection, simplifies the process and reduces the cost. cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

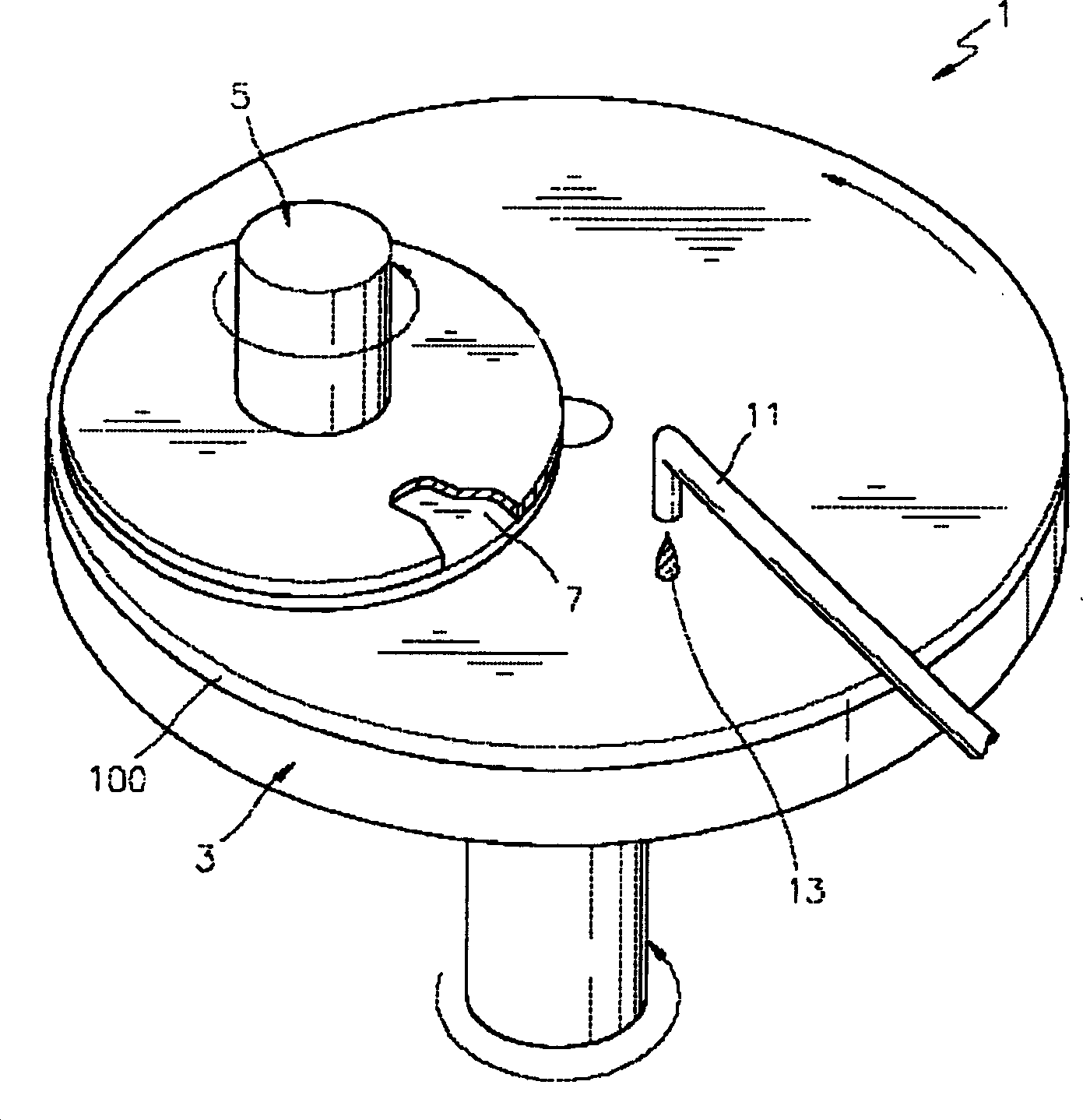

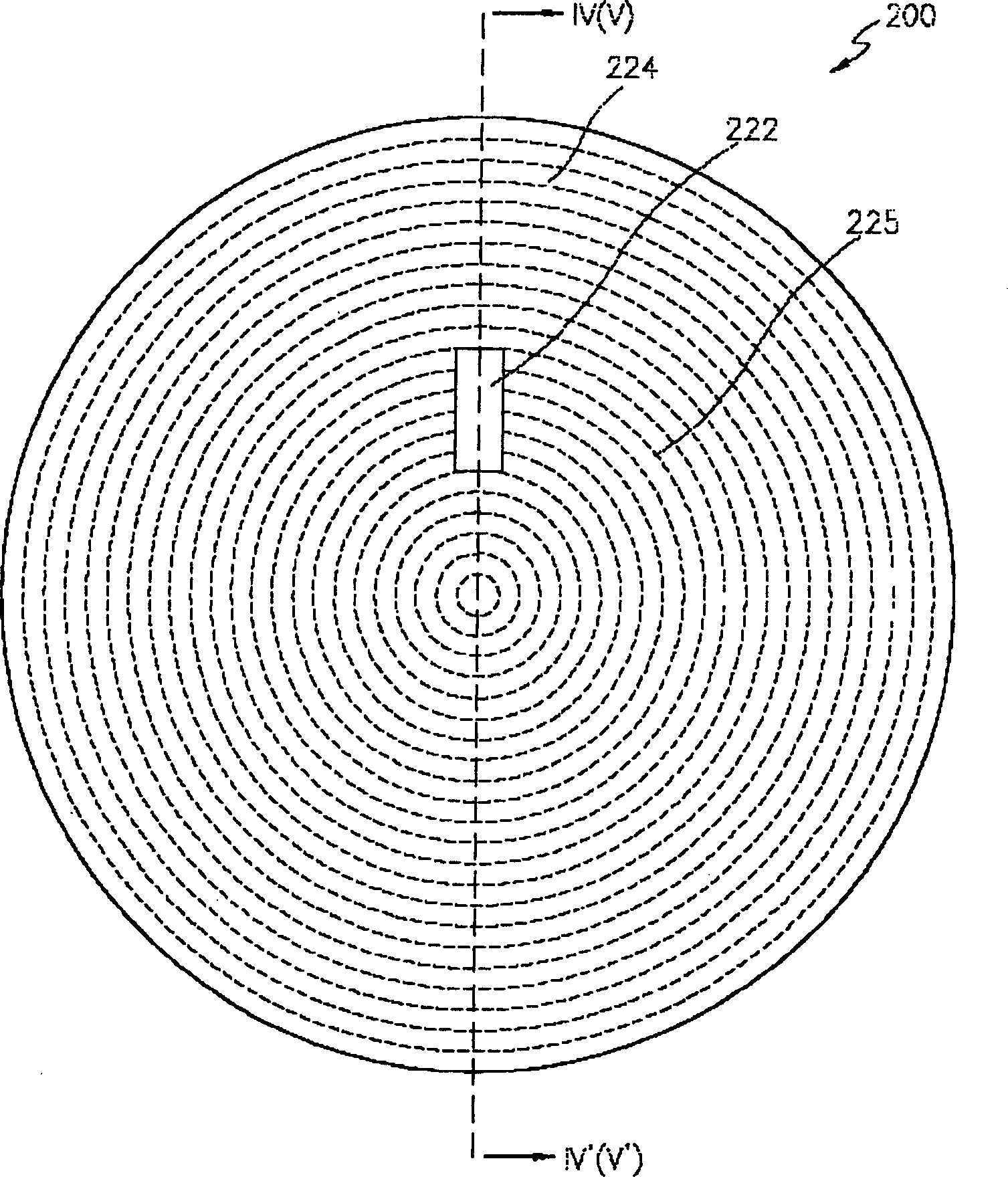

[0040] The polishing pad 200 of the second embodiment further has a transparent region 222 transparent to the light source 300 for optically detecting the surface state of the object to be polished, that is, the flatness of the wafer surface. On the surface of the polishing pad 200 is formed a texture or pattern 225 having a flow channel that facilitates the movement and delivery of the polishing slurry. Such as Figure 4 As shown, in the polishing pad 200 of Example 2, the elastic supporting layer 210, the transparent region 222 constituting the polishing layer 220, and the other region 224 are integrated. The so-called integral type, as described in Embodiment 1, means that the elastic support layer 210, the transparent region 222 of the grinding layer 220 and the other region 224 are made of materials that are chemically compatible with each other, so that the elastic support layer 210 and the There is no structural boundary between the regions 222, 224 of the abrasive lay...

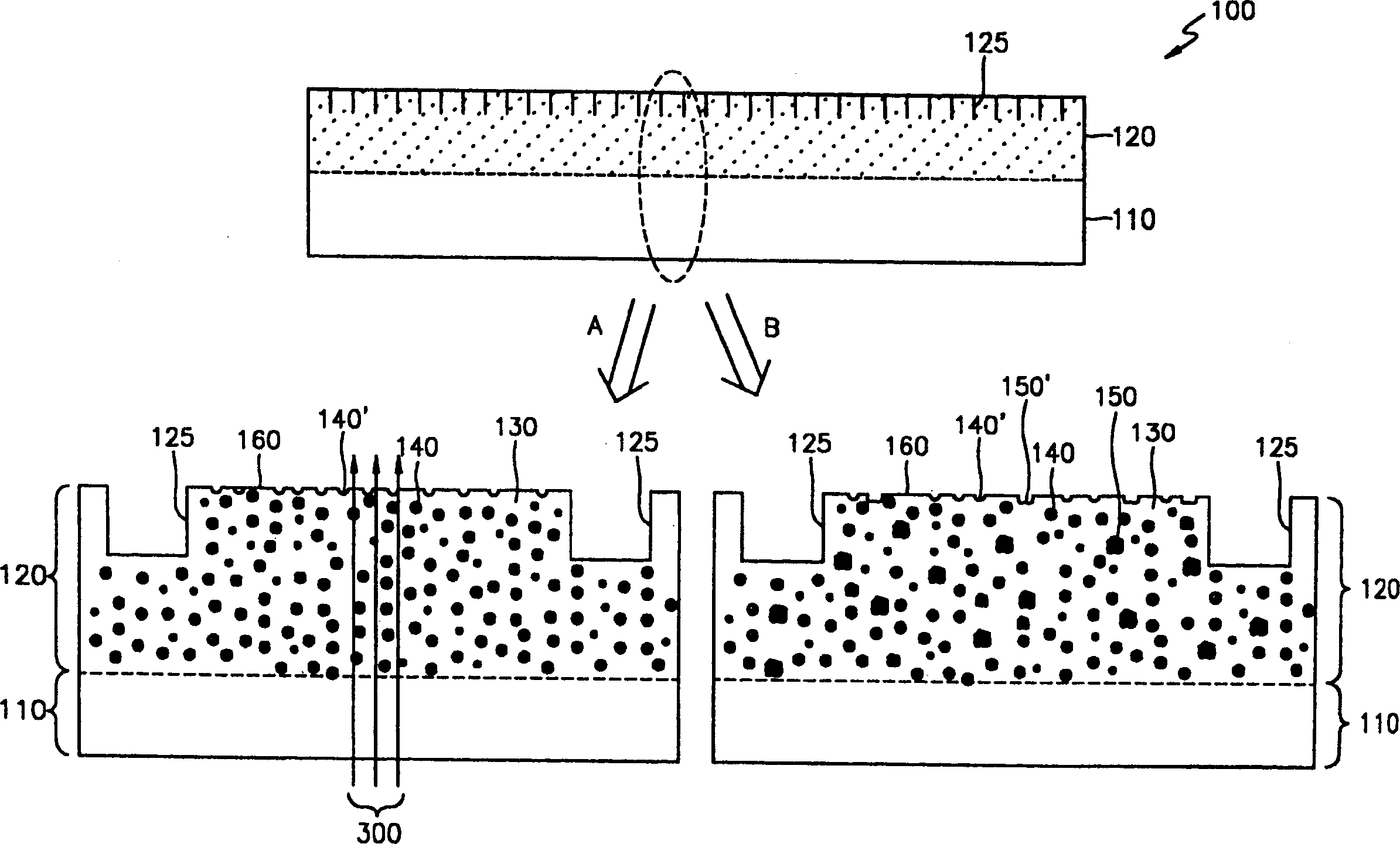

Embodiment 1

[0062] 100 g of a polyether-based isocyanate prepolymer (NCO content: 16%) and 100 g of polypropylene glycol were mixed at normal temperature, and the reaction was started. While maintaining a low viscosity, the reaction liquid was casted with a thickness of 1.5 mm, gelled for 30 minutes, and then cured in an oven at 100° C. for 20 hours. Then, the obtained cured product was cut into a certain size to manufacture a support layer. A sheet having a thickness of 1 mm was produced by the same method as that of the support layer, and cut into a size of 20 mm×50 mm to form a transparent window.

[0063] A prefabricated support layer was installed in a mold of a certain size, a transparent window was placed on the surface of the support layer, and the temperature of the mold was adjusted to 50° C. to produce a polishing layer.

[0064] Mixed polyether-based isocyanate prepolymer (NCO content 11%) 100g, mineral oil (hereinafter referred to as KF-70) (manufactured by Seojin Chemical C...

Embodiment 3

[0068] A polishing layer was produced in the same manner as in Example 1. After the obtained polishing layer was punched out to a size of 20mm×50mm to form an empty space, it was installed in a mold of a certain size, and the temperature of the mold was adjusted to 50°C.

[0069] Urethane produced according to the method of forming a transparent window in Example 1 was injected into the empty space of the abrasive layer in the above mold. Then, the urethane reactant for forming the support layer of Example 1 was injected over the polishing layer to perform casting processing. After gelling for 30 minutes, it was cured in an oven at 100° C. for 20 hours, and then removed from the mold and processed to complete the polishing pad.

[0070] According to the polishing pad of the present invention, since the elastic supporting layer and the polishing layer are integrated, the flattening efficiency of the object to be polished is improved, and since the whole is formed as a thin pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com