Linear friction welding method

A linear friction welding and welding process technology, which is applied in the field of variable amplitude linear friction welding and variable frequency, can solve the problems of poor quality of welded joints, etc., and achieve the effects of prolonging service life, eliminating residual stress, and uniform high temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

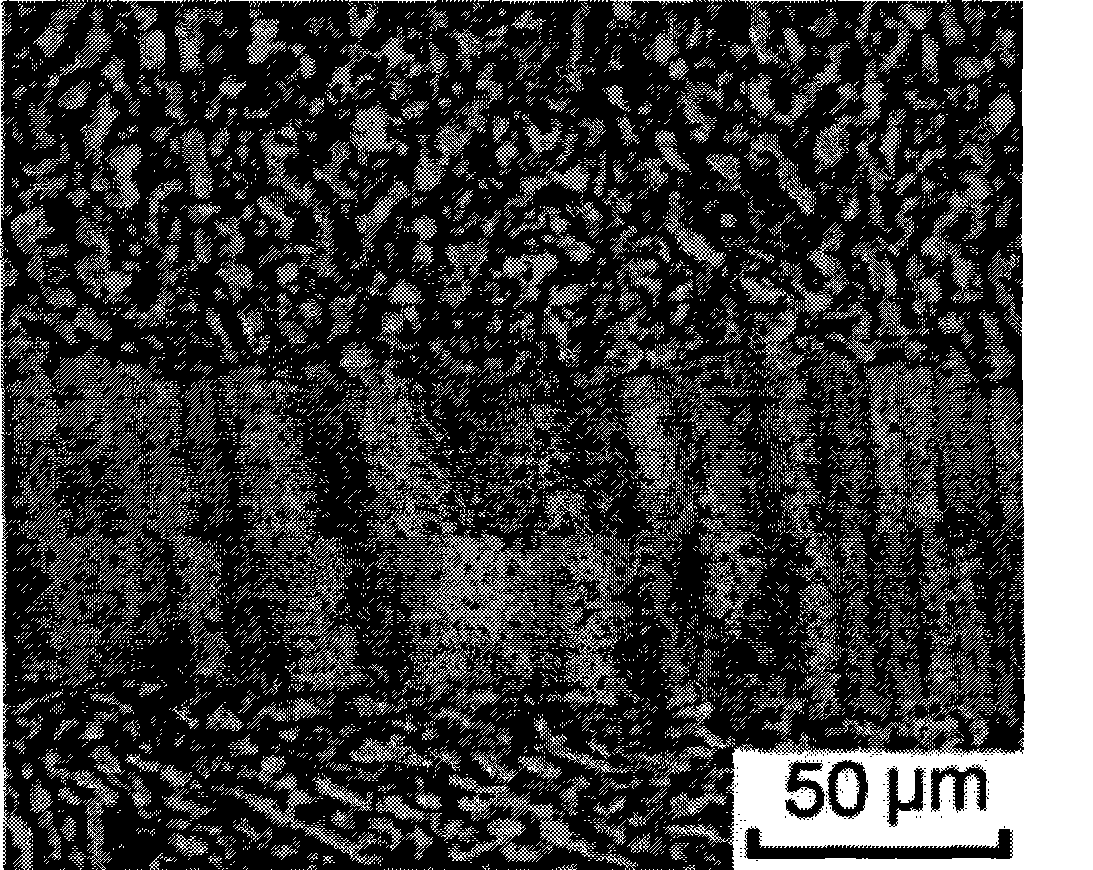

Embodiment 1

[0013] Embodiment 1: Utilize the method of the present invention to carry out the linear friction welding test of TC4 titanium alloy. The length of the welded test piece is 46mm, the welded section is 15mm×18mm, and it vibrates and rubs along the direction of the 18mm dimension during welding. The process parameters are: the vibration frequency increases linearly from 10Hz to 30Hz within 2 seconds at the beginning of the friction; then enters the friction stage with a constant frequency of 30Hz and a constant amplitude of 1.5mm for 2 seconds; then the amplitude gradually decreases from 1.5mm to 0. Friction pressure 20MPa, upsetting pressure 60MPa.

Embodiment 2

[0014] Embodiment 2: A linear friction welding test of No. 45 steel was carried out by using the method of the present invention. The length of the welded test piece is 46mm, the welded section is 20mm×60mm, and it vibrates and rubs along the 60mm dimension direction during welding. The process parameters are: the vibration frequency increases linearly from 20Hz to 60Hz within 3 seconds at the beginning of the friction; then enters the friction stage with a constant frequency of 60Hz and a constant amplitude of 2.0mm for 8 seconds; then the amplitude decreases linearly from 2.0mm to 0. Friction pressure 50MPa, upsetting pressure 100MPa.

Embodiment 3

[0015] Embodiment 3: A linear friction welding test of No. 45 steel was carried out by using the method of the present invention. The length of the welded test piece is 46mm, the welded section is 30mm×80mm, and it vibrates and rubs along the direction of 80mm dimension during welding. The process parameters are: the vibration frequency increases linearly from 30Hz to 90Hz within 4 seconds at the beginning of the friction; then enters the friction stage with a constant frequency of 90Hz and a constant amplitude of 3.0mm for 12 seconds; then the amplitude decreases linearly from 3.0mm to 0. Friction pressure 80MPa, upsetting pressure 160MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com