Extrusion molding method of nickel based alloy sphere for valve

A nickel-based alloy, extrusion forming technology, applied in valve devices and other directions, can solve problems such as mixed crystals, product scrap, cracking, etc., and achieve the effects of ensuring continuity, less machining time, and high material utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

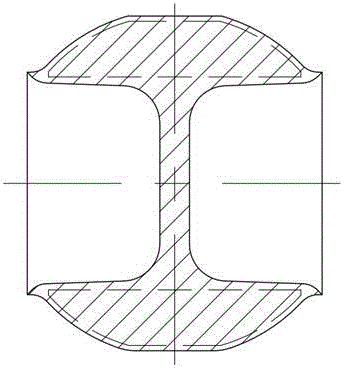

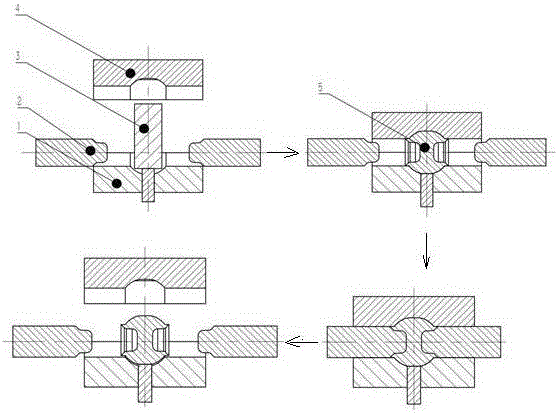

Image

Examples

Embodiment 1

[0027] Embodiment 1: a sphere whose material is Inconel625 and whose specification is DN80.

[0028] (1) Through computer numerical simulation technology, the technical parameters of a spherical extrusion made of Inconel625 and DN80 are determined as follows:

[0029] Table 1 Extrusion Technical Parameters

[0030] model Billet diameter Forging weight Initial forging temperature Final forging temperature DN80 Φ90mm 6.5 kg 1180 ℃ ≥800 ℃

[0031] (2) Cutting by sawing machine, blank weight 6.4kg-6.7kg (height reference 119.2mm-124.8mm);

[0032] (3) Preheat the billet to 100°C first, then apply lubricant and adhesive on the surface of the billet, add a soft cover, and then heat the billet to 1180°C±20°C;

[0033] (4) The mold is installed in place, and the preheating temperature reaches above 400°C;

[0034] (5) Adopt 4000T multifunctional metal extrusion machine, set the extrusion program, adopt pressure control for the upper die, and adopt d...

Embodiment 2

[0041] Embodiment 2: a sphere whose material is Incoloy825 and whose specification is DN200.

[0042] (1) The technical parameters of a spherical extrusion made of Incoloy825 and DN200 are determined by computer numerical simulation technology as follows:

[0043] Table 2 Extrusion Technical Parameters

[0044] model Billet diameter Forging weight Initial forging temperature Final forging temperature DN200 Φ200mm 130kg 1200 ℃ ≥800 ℃

[0045] (2) Cutting by sawing machine, blank weight 129kg-131kg (height reference 486.7mm-494.3mm);

[0046] (3) Preheat the billet to 100°C first, then apply lubricant and adhesive on the surface of the billet, add a soft cover, and then heat the billet to 1180°C±20°C;

[0047] (4) The mold is installed in place, and the preheating temperature reaches above 400°C;

[0048] (5) Adopt a 12000T multi-functional metal extrusion machine, set the extrusion program, adopt pressure control for the upper die, and adopt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com