Production method of large-specification nickel-base high-temperature alloy forged piece

A technology of nickel-based superalloy and production method, which is applied in the direction of metal processing equipment, etc., can solve the problems of no reference value and impact performance that cannot meet the requirements, and achieve the effects of ensuring uniformity, reducing edge temperature loss, and excellent impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1 The method for producing large-size nickel-based superalloy forgings of the present invention includes the following steps:

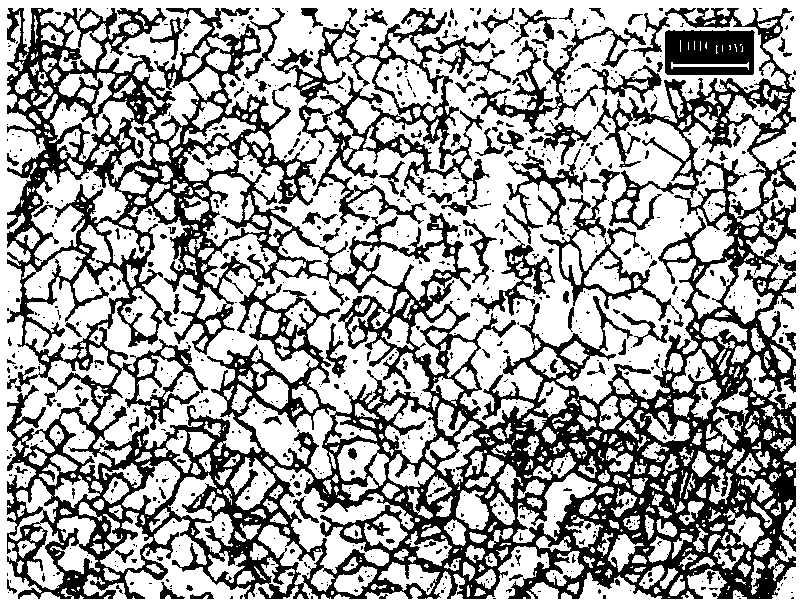

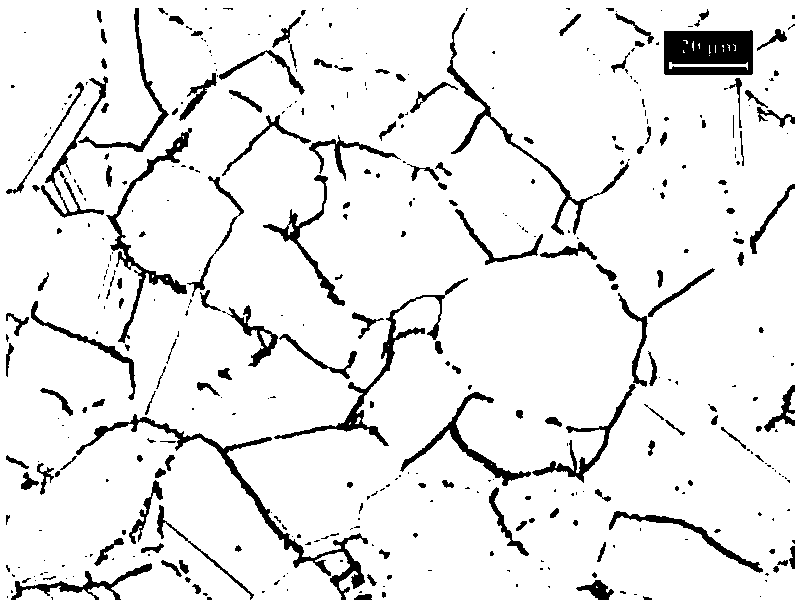

[0044] The GH4169 alloy billet is prepared by the conventional fast forging process, and the grain structure of the billet reaches 5 or finer. The grain structure of the intermediate billet is shown in the photo Figure 1-2 .

[0045] The surface of the blank is ground, and then cut to length. The size of the blank is φ200×440mm, and the aspect ratio is 2.2.

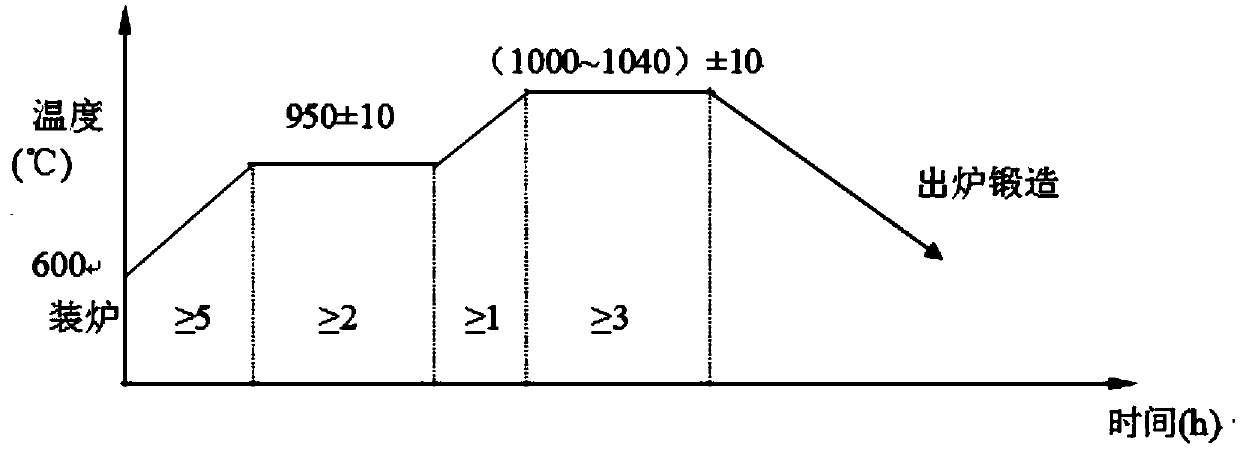

[0046] The billet is heated in a heating furnace, see the heating process image 3 , The holding temperature is 1040℃.

[0047] After the billet reaches temperature, it is quickly transferred to the press. After adjusting the billet position, make sure that its upper and lower end faces are parallel; press the disc at a deformation rate of 20mm / s, and control the deformation according to the height. The deformed forging is immediately taken out and air-cooled.

[0048] The surface condit...

Embodiment 2

[0049] Example 2 A method for producing large-size nickel-based high-temperature alloy forgings of the present invention includes the following steps:

[0050] The GH4169 alloy billet is prepared by the radial forging process, and the grain structure of the billet reaches level 5 or finer.

[0051] The surface of the blank is ground, and then cut to length. The size of the blank is φ200×480mm, and the height-to-diameter ratio is 2.4.

[0052] The billet is heated in a heating furnace, see the heating process image 3 , The holding temperature is 1000℃.

[0053] After the blank reaches the temperature, it is quickly transferred to the press. After adjusting the position of the blank, make sure that its upper and lower ends are parallel; press the disc at a deformation rate of 20mm / s, and control the amount of deformation according to the height. The deformed forgings are taken out immediately and air-cooled.

[0054] The surface condition of the forged blanks is poor, and the size speci...

Embodiment 3

[0055] Example 3 A method for producing large-size nickel-based high-temperature alloy forgings of the present invention includes the following steps:

[0056] The GH4169 alloy billet is prepared by the rapid forging process, and the grain structure of the intermediate billet reaches level 5 or finer.

[0057] The surface of the blank is ground, and then cut to length. The size of the blank is φ200×440mm, and the aspect ratio is 2.2.

[0058] The billet is heated in a heating furnace, see the heating process image 3 , The holding temperature is 1000℃.

[0059] After the blank reaches the temperature, it is quickly transferred to the press. After adjusting the position of the blank, make sure that its upper and lower ends are parallel. Press the disc at a deformation rate of 30mm / s, and control the amount of deformation according to the height. The deformed forgings are taken out immediately and air-cooled.

[0060] The surface condition of the forged blanks is poor, and the size spec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com