Method for manufacturing boron-containing diamond compact

A technology of boron diamond and composite sheet, which is applied in the field of preparation of superhard materials, can solve the problems of difficult to stabilize the quality of boron-containing diamond composite sheet, different degree of uniformity, and poor stability of boron-containing diamond, so as to improve comprehensive performance and anti-oxidation Sexual improvement, high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The binding agent that adopts in the present embodiment comprises following raw material components and parts by weight:

[0042] Co powder 97 parts by weight

[0043] TiC powder 2 parts by weight

[0044] 1 part by weight of Ni powder.

[0045] In this example:

[0046] In step 1), the concentration of the boric acid aqueous solution is 3%.

[0047] In step 1), the mass volume ratio of the diamond powder and the boric acid aqueous solution is 500g / L.

[0048] In step 2), the drying temperature is 200°C.

[0049] The mass ratio of diamond micropowder and binding agent is 1 in step 3).

[0050] In step 4), the cemented carbide substrate is WC-Co cemented carbide.

[0051] In step 4), the high temperature is 1400° C., and the high pressure is 7.5 MPa.

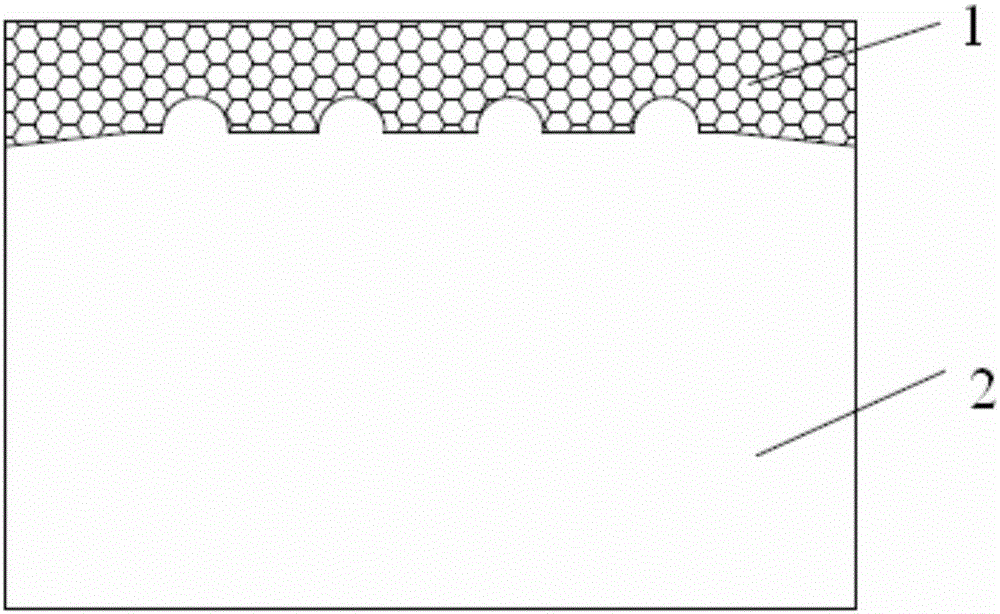

[0052] In this embodiment, the thickness of the boron-containing diamond layer is 0.5-1.5 mm; the thickness of the cemented carbide matrix layer is 5-10 mm.

Embodiment 2

[0054] The binding agent that adopts in the present embodiment comprises following raw material components and parts by weight:

[0055] Co powder 98 parts by weight

[0056] TiC powder 0.5 parts by weight

[0057] Ni powder 1.5 parts by weight.

[0058] In this example:

[0059] In step 1), the concentration of the boric acid aqueous solution is 10%.

[0060] In step 1), the mass volume ratio of the diamond powder to the boric acid aqueous solution is 600g / L.

[0061] In step 2), the drying temperature is 300°C.

[0062] The mass ratio of diamond micropowder and bonding agent is 2 in step 3).

[0063]In step 4), the cemented carbide substrate is WC-Co cemented carbide.

[0064] In step 4), the high temperature is 1500° C., and the high pressure is 6 MPa.

[0065] In this embodiment, the thickness of the boron-containing diamond layer is 0.5-2.5 mm; the thickness of the cemented carbide matrix layer is 5-10 mm.

Embodiment 3

[0067] The binding agent that adopts in the present embodiment comprises following raw material components and parts by weight:

[0068] Co powder 99 parts by weight

[0069] TiC powder 0.5 parts by weight

[0070] Ni powder 0.5 parts by weight.

[0071] In this example:

[0072] In step 1), the concentration of the boric acid aqueous solution is 15%.

[0073] In step 1), the mass volume ratio of the diamond powder to the boric acid aqueous solution is 700g / L.

[0074] In step 2), the drying temperature is 400°C.

[0075] The mass ratio of diamond micropowder and bonding agent is 3 in step 3).

[0076] In step 4), the cemented carbide substrate is WC-Co cemented carbide.

[0077] In step 4), the high temperature is 1600° C., and the high pressure is 7 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com