Thin-gauge, ultra-low iron loss, low-noise and high-magnetic induction oriented silicon steel sheet and production method thereof

A technology of oriented silicon steel and silicon steel sheet, which is applied in the field of iron core materials for power transmission and distribution transformers in the power industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

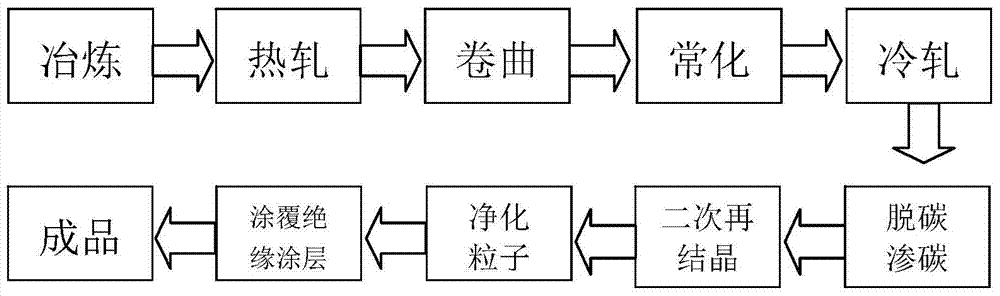

Method used

Image

Examples

Embodiment 1

[0042] Silicon steel slabs were smelted in a 500Kg vacuum melting furnace, and the casting components were shown in Table 1.

[0043] Table 1 Chemical composition (wt%) of billet, the balance is Fe

[0044] C

[0045] Heat the cast slab to 1150-1170°C, keep it warm for 2.5 hours, hot-roll it to 3mm, and curl it with a final reduction of 85%, then perform normalization treatment, heat it at 900-1100°C for 1-5 minutes for annealing, and The final forming cold rolling of the plate is carried out on the rolling mill, the reduction is 90%, and the thickness is controlled at 0.18mm. Then decarburization and nitriding are carried out, water vapor is introduced during decarburization, the final C content is controlled at 450ppm, and NH is introduced during nitriding 3 , carried out at 800°C and coated with glass film, and finally annealed at 1110-1120°C at high temperature, under the protection of pure nitrogen, raised to 450°C for 3 hours, removed water vapor and isolated ...

Embodiment 2

[0051] Silicon steel slabs were smelted in a 500Kg vacuum melting furnace, and the casting components were shown in Table 3.

[0052] Table 3 Chemical composition (wt%) of billet, the balance is Fe

[0053] C

[0054] Heat the cast slab to 1160-1180°C, heat it for 3 hours and then rough roll it for 2 passes, then finish rolling it for 3 passes. The final reduction is 80%, hot rolling to 3mm, crimping, and then normalizing treatment. Heat preservation at 900-1000°C for 1-5 minutes for annealing, and final cold-rolling of the plate on a cold rolling mill, with the thickness controlled at 0.18mm. Subsequent decarburization is carried out to control the final C content at 300ppm, and NH is introduced during nitriding 3 , carried out at 800°C, and coated with glass film; finally, the high-temperature annealing was raised to 500°C for 3.5 hours under the protection of pure nitrogen, to remove water vapor and isolate the air; under the condition of nitrogen:hydrogen ratio ...

Embodiment 3

[0060] Silicon steel slabs were smelted in a 500Kg vacuum melting furnace, and the casting composition was shown in Table 5.

[0061] Table 5 Chemical composition (wt%) of steel billet, the balance is Fe

[0062] C

[0063] Heat the billet to 1200-1240°C, keep it warm for 2.3 hours, hot-roll it to 3mm, crimp it, then carry out normalization treatment, heat it at 950-1050°C for 1-5 minutes for annealing, and carry out the final forming of the plate on a cold rolling mill Cold rolling, the thickness is controlled at 0.18mm. Water vapor is then introduced during decarburization to control the final C content at 300ppm, and NH is introduced during nitriding 3 , carried out at 800°C, and coated with glass film, and finally under the protection of pure nitrogen, raised to 400°C for 2 hours to remove water vapor and isolate the air; under the condition of nitrogen:hydrogen ratio of 1:3, the heating rate was 40°C Raise the temperature of the furnace to 1120-1150°C per hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com