430 ferritic stainless steel for kitchen ware panels and preparation method thereof

A ferritic and stainless steel technology, applied in the field of 430 ferritic stainless steel for kitchenware panels and its preparation, can solve the problems of yield platform, easy wrinkling, low elongation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

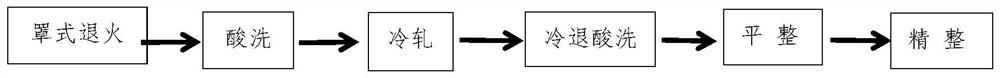

Method used

Image

Examples

Embodiment Construction

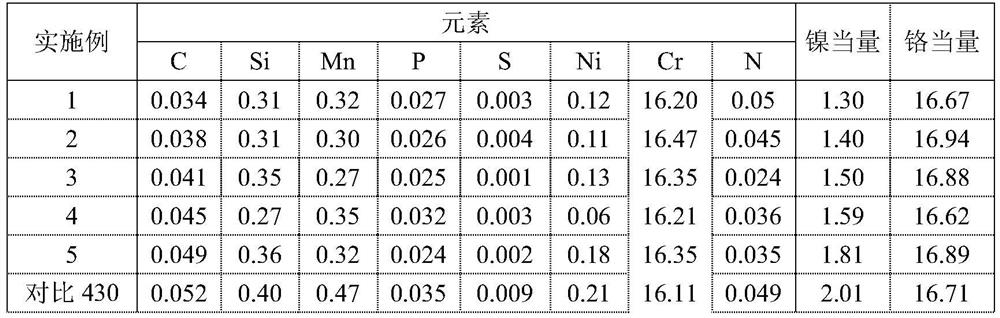

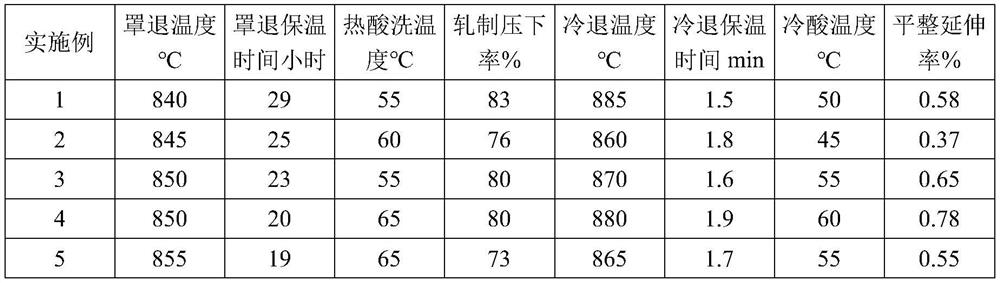

[0034] Below in conjunction with embodiment the present invention is described in further detail.

[0035] A kind of 430 ferritic stainless steel for kitchenware panel, the mass percent of each component of this 430 ferritic stainless steel is:

[0036] C: 0.030~0.05%

[0037] N: 0.020~0.05%

[0038] Si: 0.20-0.40%

[0039] Ni: ≤0.20%

[0040] Mn: ≤0.35%

[0041] Cr: 16.00~16.50%

[0042] P: less than or equal to 0.035%

[0043] S: less than or equal to 0.010%

[0044] The rest is Fe and unavoidable impurity elements. Elements such as Ni, Mn, P, and S are theoretically as small as possible, but due to reasons such as smelting technology and cost control, there are currently no examples of these elements being 0.

[0045] C is a strong austenite forming element, and its ability to form austenite is 30 times that of Ni, which promotes the development of the 430 stainless steel matrix to the ferrite + martensite two-phase region. At the same time, C is an interstitial sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com