Gas shielded flux-cored welding wire for vertical mill grinding roller bead welding composite manufacture and preparation method thereof

A technology of flux-cored welding wire and gas shielding, which is applied in the direction of manufacturing tools, welding equipment, welding equipment, etc., can solve the problems of large powder filling coefficient and difficulty in welding wire production and manufacturing, achieve less smoke and dust, reduce cleaning and grinding after welding, and weld The effect of excellent process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

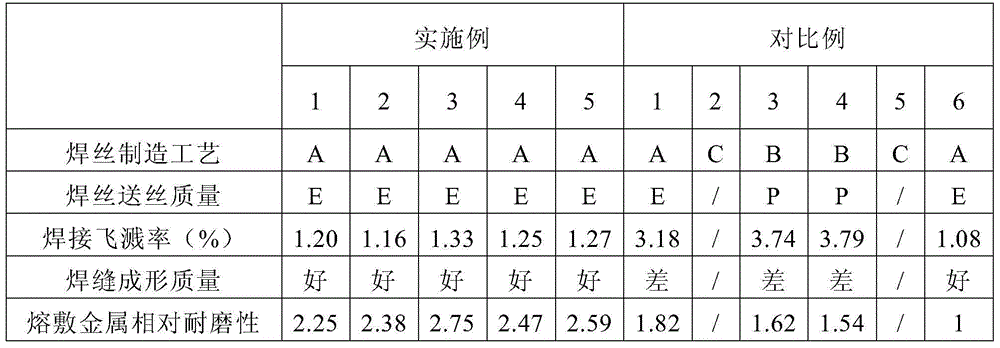

Examples

Embodiment 1

[0037]Select a ferritic stainless steel strip with a thickness of 0.4mm and a width of 10mm, and roll it into a U shape; 610g of high-carbon ferrochromium powder, 130g of chromium carbide powder, 58g of graphite, 12g of electrolytic manganese metal, 40g of silicon carbide powder, and 12g of aluminum-magnesium Alloy, 3g zircon sand, 5g cryolite, 5g sodium fluoride, 5g lithium carbonate, 120g iron powder, a total of 1000g powder, mix evenly and add to the U-shaped tank, the filling rate is 25%; , φ1.90mm, φ1.67mm, φ1.45mm, φ1.23mm, φ1.15mm six-pass cassette die combination eye mold drawing and reducing diameter, the final finished wire diameter is 1.2mm.

Embodiment 2

[0039] Select a ferritic stainless steel strip with a thickness of 0.4mm and a width of 10mm, and roll it into a U shape; 640g of high-carbon ferrochromium powder, 150g of chromium carbide powder, 60g of graphite, 18g of electrolytic manganese metal, 45g of silicon carbide powder, and 18g of aluminum-magnesium Alloy, 5g zircon sand, 8g cryolite, 9g sodium fluoride, 12g lithium carbonate, 35g iron powder, a total of 1000g powder, mixed evenly and added to the U-shaped tank, the filling rate is 28%; after closing, pass through φ2.50mm , φ1.90mm, φ1.67mm, φ1.45mm, φ1.23mm, φ1.15mm six-pass cassette die combination eye mold drawing and reducing diameter, the final finished wire diameter is 1.2mm.

Embodiment 3

[0041] Select a ferritic stainless steel strip with a thickness of 0.4mm and a width of 10mm, and roll it into a U shape; 620g of high-carbon ferrochrome powder, 135g of chromium carbide powder, 59g of graphite, 15g of electrolytic manganese metal, 43g of silicon carbide powder, and 15g of aluminum-magnesium Alloy, 4g zircon sand, 7g cryolite, 8g sodium fluoride, 8g lithium carbonate, 86g iron powder, a total of 1000g powder, mixed evenly and added to the U-shaped groove, the filling rate is 27%; , φ1.90mm, φ1.67mm, φ1.45mm, φ1.23mm, φ1.15mm six-pass cassette die combination eye mold drawing and reducing diameter, the final finished wire diameter is 1.2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com