Preparation method of NbTi/CuNi superconducting switch wire with high Ni content

A technology of superconducting switching and content, applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc., can solve the problems of surface tearing, work hardening, etc., so as to reduce the work hardening problem and realize mass production The effect of chemical production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A method for preparing a NbTi / CuNi superconducting switch wire with high Ni content, characterized in that the specific operation process includes the following steps:

[0035] S1, using the CuNi alloy smelted by the intermediate frequency furnace as the billet, and then preparing the billet into CuNi tube billet and ingot, and adding the CuNi tube billet and ingot machine into NbTi / CuNi primary sheathing and secondary sheathing; CuNi alloy The grains are equiaxed, and the content of Ni in the alloy is 30-50wt.%.

[0036] S2. Assemble the NbTi / CuNi primary sheath and NbTi rod in step S1 to prepare a NbTi / CuNi primary composite billet, and then prepare a NbTi / CuNi primary billet through vacuum electron beam welding and hot extrusion; wherein, The preheating temperature for hot extrusion is 600°C-900°C, the holding time is 2h-6h, and the extrusion ratio is 3-15.

[0037] S3. Use a high-hardness tungsten carbide peeling die to peel off the NbTi / CuNi primary billet to remo...

Embodiment 1

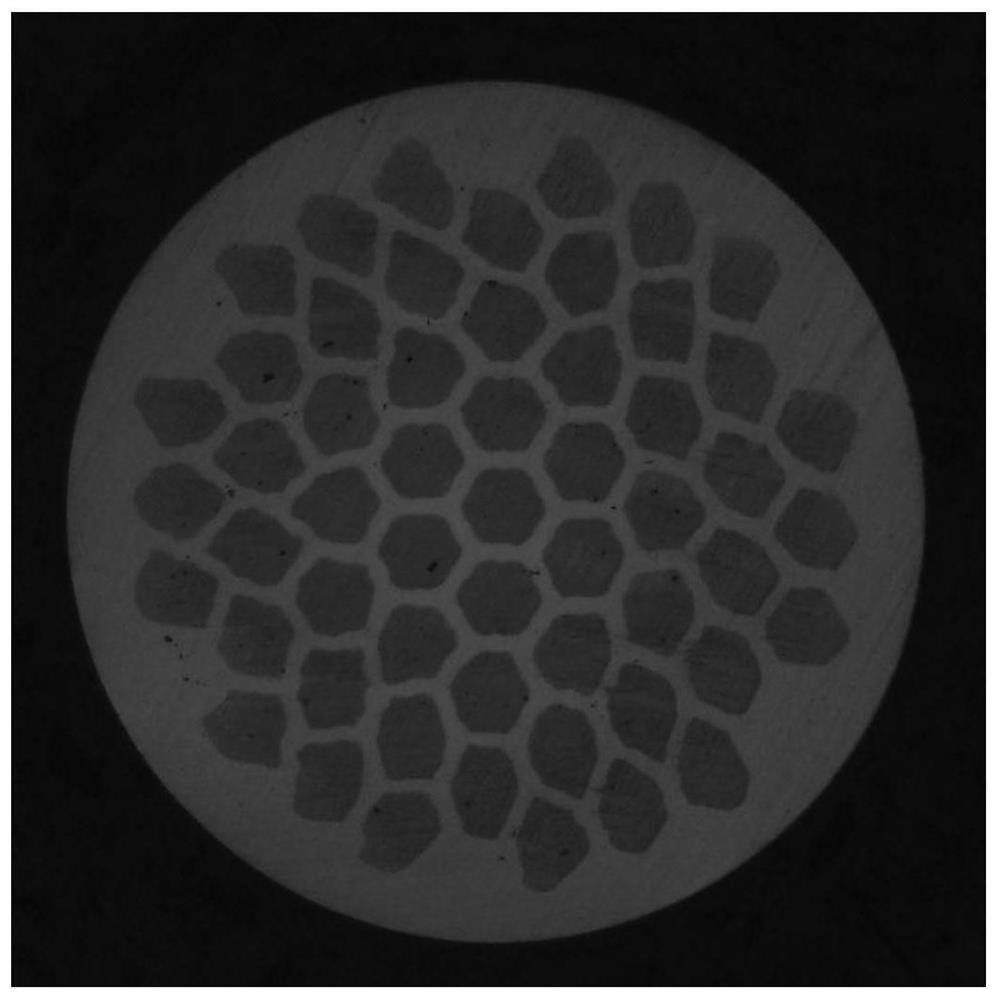

[0043] Such as figure 1 As shown, the present invention provides a kind of preparation method of the NbTi / CuNi superconducting switch wire of high Ni content, and concrete operation process comprises the following steps:

[0044] S1. Using a CuNi alloy smelted in an intermediate frequency furnace with a Ni content of 35wt.% and equiaxed crystal grains as the billet, the billet is then prepared into a CuNi tube billet and an ingot, and the CuNi tube billet and the ingot billet are added as an external A NbTi / CuNi primary sheath with a diameter of 63mm and a secondary sheath with an outer diameter of 97mm.

[0045] S2. Use the assembly method to assemble the NbTi / CuNi primary sheath and the NbTi rod in step S1 once to prepare a NbTi / CuNi primary composite ingot, and then prepare a NbTi / CuNi primary rod through vacuum electron beam welding and hot extrusion billet; wherein, the hot extrusion preheating temperature is 700°C, the holding time is 2h, and the extrusion ratio is 15. ...

Embodiment 2

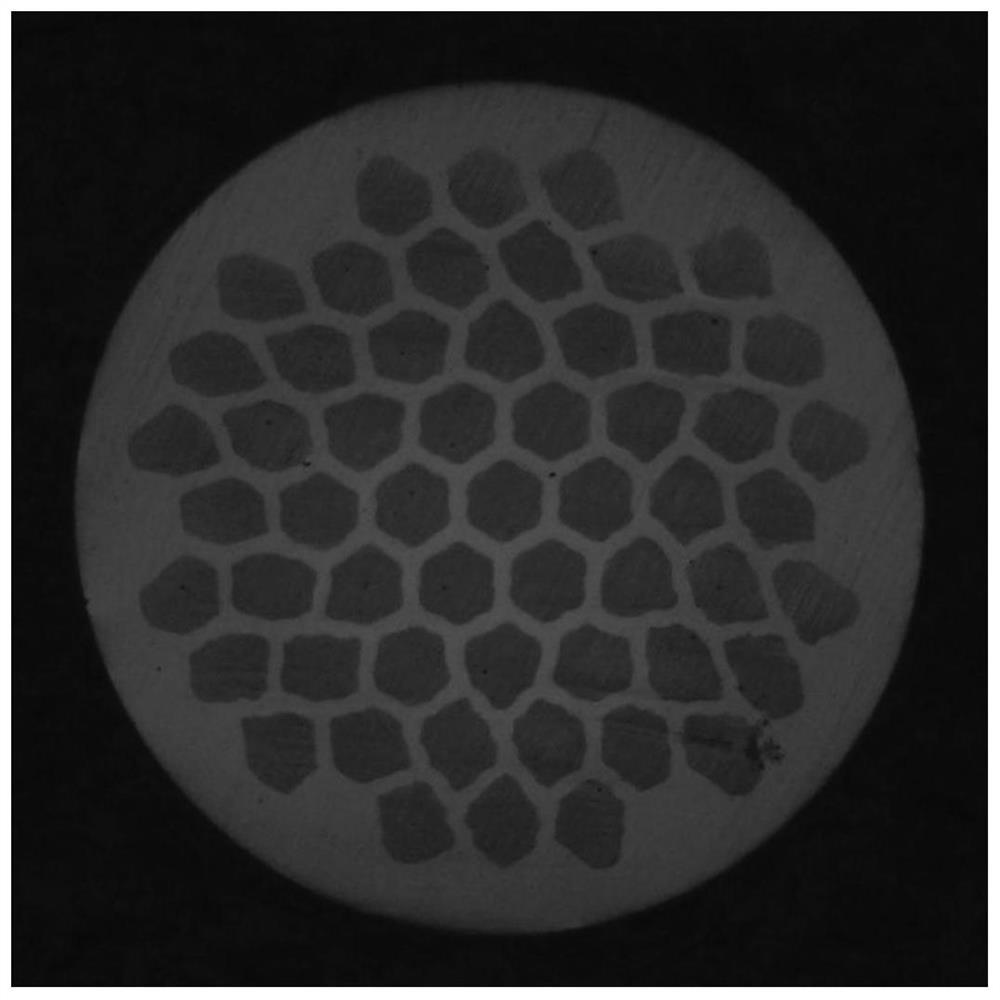

[0052] Such as figure 2 As shown, the present invention provides a kind of preparation method of the NbTi / CuNi superconducting switch wire of high Ni content, and concrete operation process comprises the following steps:

[0053] S1. Using a CuNi alloy smelted in an intermediate frequency furnace, with a Ni content of 40wt.%, and equiaxed crystal grains, as a billet, and then preparing the billet into a CuNi tube billet and an ingot, and adding the CuNi tube billet and ingot billet into a NbTi / CuNi primary sheath with outer diameter of 63mm and secondary sheath with outer diameter of 97mm;

[0054] S2. Use the assembly method to assemble the NbTi / CuNi primary sheath and NbTi rod in step S1 to prepare a NbTi / CuNi primary composite ingot, and then prepare a NbTi / CuNi primary billet through vacuum electron beam welding and hot extrusion ; Among them, the hot extrusion preheating temperature is 750°C, the holding time is 4h, and the extrusion ratio is 10.

[0055] S3. Use a hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com