Manufacturing method of metal plate

A technology of sheet metal and manufacturing method, which is applied in the field of flexible manufacturing of sheet metal with different specifications, and can solve problems such as unsatisfactory market and long production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment is a method for manufacturing 30CrMnSiA steel plate, the specification of the steel plate is a×b×t=600×800×2.2+0.20mm, wherein: a is the length of one side of the plate, b is the other side of the plate length, and t is the thickness of the plate.

[0025] The specific process is:

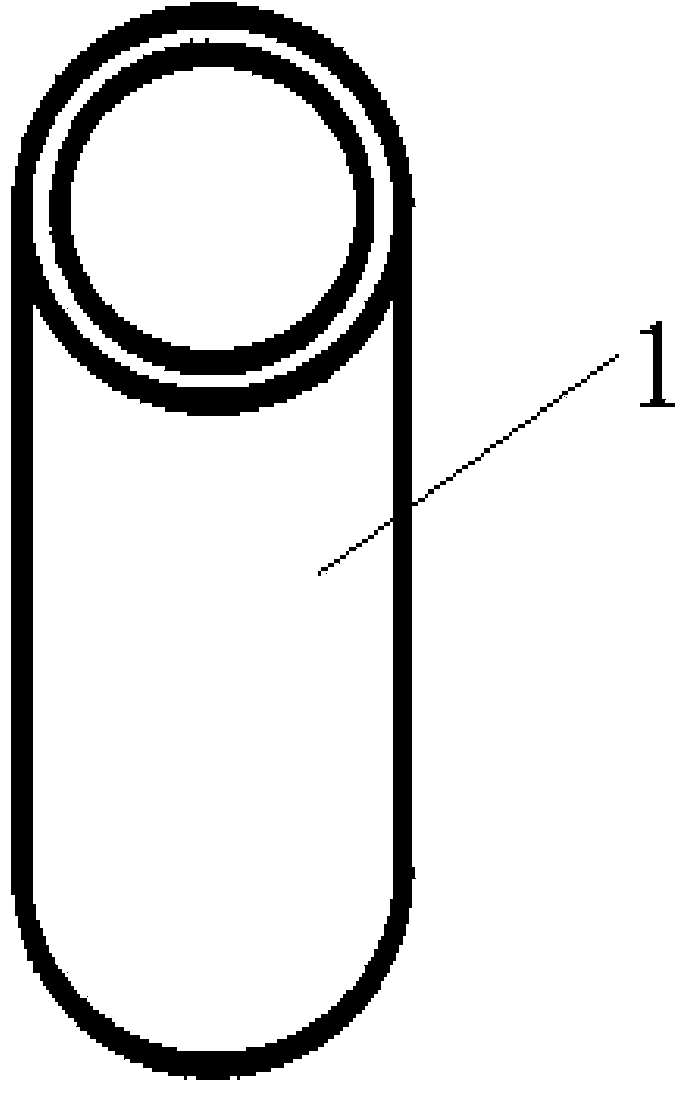

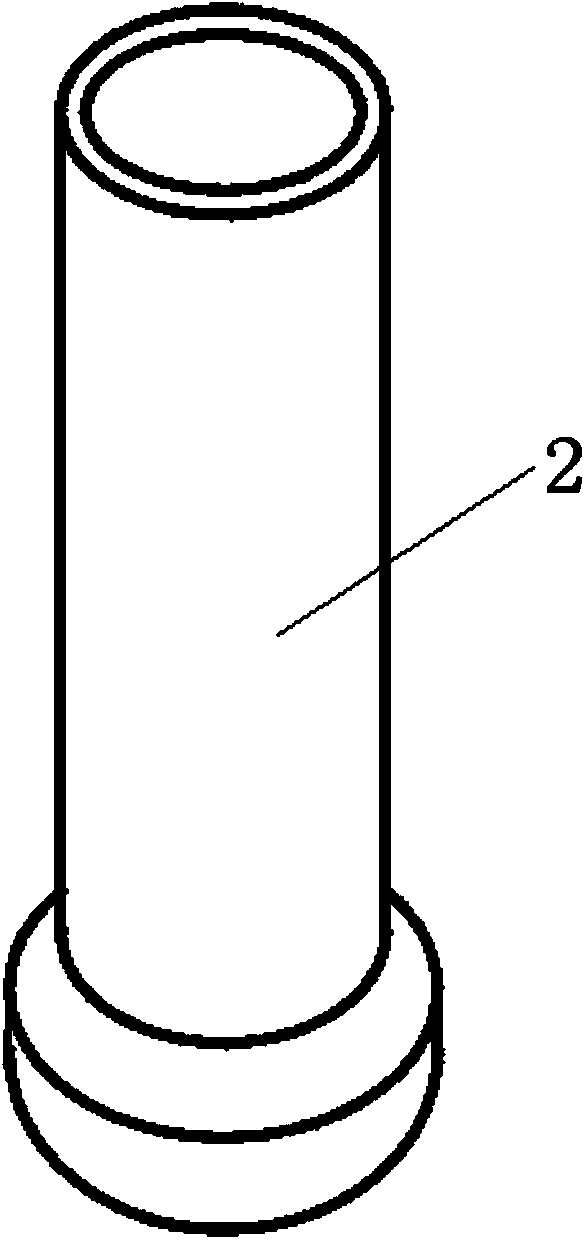

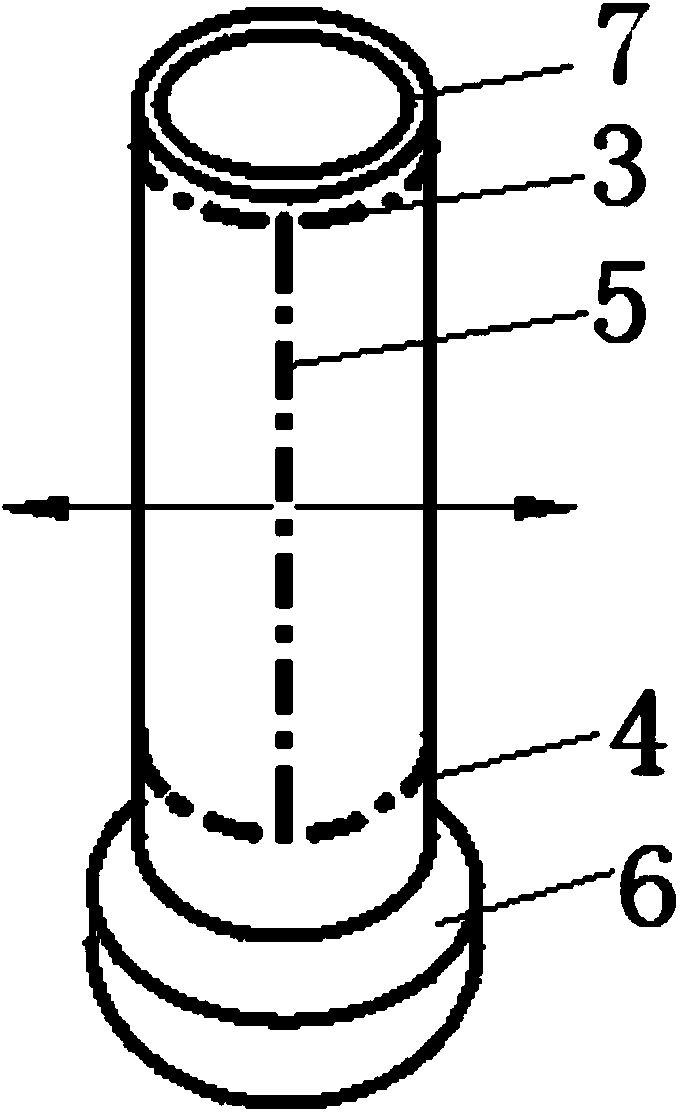

[0026] Step 1, manufacturing the blank of the spinning cylinder. The spinning cylinder blank is processed by a seamless pipe machine. The external dimensions of the spinning cylinder blank include the diameter, length and wall thickness of the cylinder blank. in:

[0027] The billet diameter D is determined by the formula (1),

[0028] D=a / π+△D (1)

[0029] The barrel length L is determined by the formula (2),

[0030] L=tb(D+t) / (D+t 0 )t 0 +△L (2)

[0031] The limit thinning rate of the material is determined according to formula (3),

[0032] ψ max ≈ψ / (0.17+ψ) (3)

[0033] In the formula (1) and formula (2), D is the inner diameter of the spinning shell, △D is t...

Embodiment 2

[0046] This embodiment is a method for manufacturing a red copper plate. The specification of the red copper plate is a×b×t=300×500×1.5+0.150mm, wherein: a is the length of one side of the plate, and b is the length of the other side of the plate , t is the thickness of the plate.

[0047] The specific process is:

[0048] Step 1, manufacturing the blank of the spinning cylinder. The spinning cylinder blank is machined from copper rods. The external dimensions of the spinning cylindrical billet include the diameter, length and wall thickness of the billet.

[0049] in:

[0050] The billet diameter D is determined by the formula (1),

[0051] D=a / π+△D (1)

[0052] The barrel length L is determined by the formula (2),

[0053] L=tb(D+t) / (D+t 0 )t 0 +△L (2)

[0054] The limit thinning rate of the material is determined according to formula (3),

[0055] ψ max ≈ψ / (0.17+ψ) (3)

[0056] In this embodiment, according to the formula (1) the shell diameter D=300 / π+△D≈100mm,...

Embodiment 3

[0064] This embodiment is a method for manufacturing a 3A21 aluminum plate. The specification of the aluminum plate is a×b×t=100×400×3.7±0.2mm, wherein: a is the length of one side of the plate, and b is the length of the other side of the plate , t is the thickness of the plate.

[0065] The specific process is:

[0066] Step 1, manufacturing the billet of the spinning cylinder:

[0067] in:

[0068] The billet diameter D is determined by the formula (1),

[0069] D=a / π+△D (1)

[0070] The barrel length L is determined by the formula (2),

[0071] L=tb(D+t) / (D+t 0 )t 0 +△L (2)

[0072] The limit thinning rate of the material is determined according to formula (3),

[0073] ψ max ≈ψ / (0.17+ψ) (3)

[0074] In this embodiment, the spinning cylindrical blank is made of a 3A21 aluminum plate, which is generally spun to form a cup with a bottom. The thickness of the aluminum plate is 8mm, and the diameter is φ260mm. The thickness of the cup wall after general rotation fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com