Forging processing technique for Fe-Si-B magnetic material

A magnetic material and processing technology, applied in the field of Fe-Si-B magnetic material forging and heating, can solve the problems of alloy ingot fracture and inability to forge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

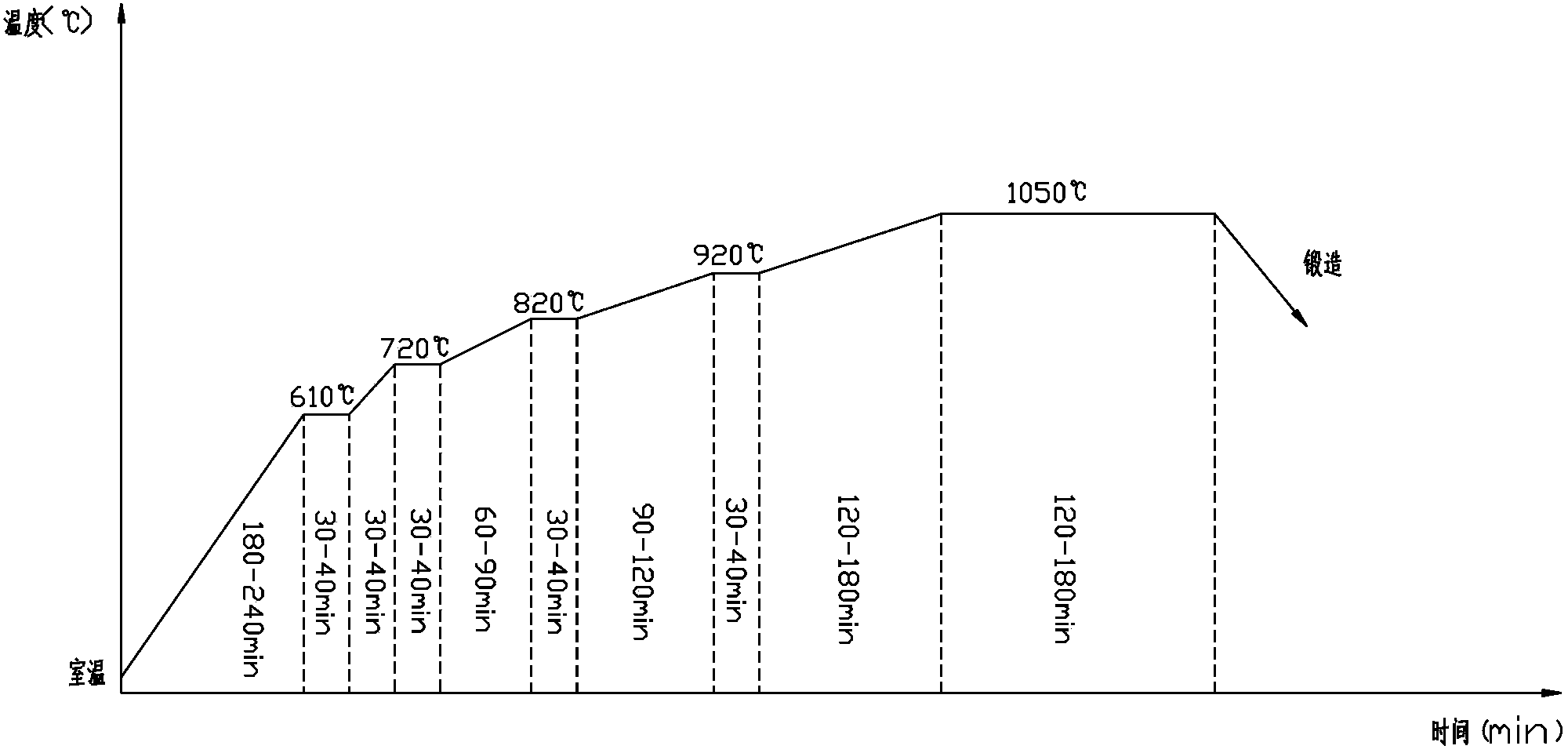

[0020] A forging process of Fe-Si-B magnetic material, including the following steps:

[0021] (1) Put the Fe-Si-B magnetic material blank into the furnace at room temperature;

[0022] (2) Slowly heat to 610℃, with a heating rate of 100℃ / h, keep at 610℃ for 30 minutes;

[0023] (3) Continue the second stage of heating, heating from 610°C to 720°C within 30 minutes, and keep it at 720°C for 40 minutes;

[0024] (4) Continue the third stage of heating, heating from 720°C to 820°C within 60 minutes, and keep it at 820°C for 40 minutes;

[0025] (5) Continue the fourth stage of heating, heating from 820°C to 920°C within 90 minutes, and keep it at 920°C for 40 minutes;

[0026] (6) Continue the fifth stage of heating, heating from 920°C to 1080°C at the top temperature within 180 minutes, and keep the temperature at the top temperature for 120 minutes;

[0027] (7) At the beginning of forging, the initial forging temperature is 1050°C, and the final forging temperature is 900°C. The relative...

Embodiment 2

[0029] A forging process of Fe-Si-B magnetic material, including the following steps:

[0030] (1) Put the Fe-Si-B magnetic material blank into the furnace at room temperature;

[0031] (2) Slowly heat to 610°C, the heating rate is 80°C / h, and keep at 610°C for 40 minutes;

[0032] (3) Continue the second stage of heating, heating from 610°C to 720°C within 40 minutes, and keeping it at 720°C for 30 minutes;

[0033] (4) Continue the third stage of heating, heating from 720°C to 820°C within 90 minutes, and keeping it at 820°C for 30 minutes;

[0034] (5) Continue the fourth stage of heating, heating from 820°C to 920°C within 120 minutes, and keeping it at 920°C for 40 minutes;

[0035] (6) Continue the fifth stage of heating, heating from 920°C to 1080°C at the top temperature within 120 minutes, and keeping the temperature at the top temperature for 180 minutes;

[0036] (7) At the beginning of forging, the initial forging temperature is 1040°C, and the final forging temperature is 900...

Embodiment 3

[0038] A forging process of Fe-Si-B magnetic material, including the following steps:

[0039] (1) Put the Fe-Si-B magnetic material blank into the furnace at room temperature;

[0040] (2) Slowly heat to 610°C with a heating rate of 150°C / h, and keep it at 610°C for 35 minutes;

[0041] (3) Continue the second stage of heating, heating from 610°C to 720°C within 35 minutes, and keeping it at 720°C for 35 minutes;

[0042] (4) Continue the third stage of heating, heating from 720°C to 820°C within 80 minutes, and keeping it at 820°C for 35 minutes;

[0043] (5) Continue the fourth stage heating, heating from 820°C to 920°C within 100 minutes, and keep it at 920°C for 30 minutes;

[0044] (6) Continue the fifth stage of heating, heating from 920°C to 1080°C at the top temperature within 150 minutes, and keep the temperature at the top temperature for 160 minutes;

[0045] (7) At the beginning of forging, the initial forging temperature is 1060°C, and the final forging temperature is 900°C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com