A kind of steel with high r value and thick specification IF automobile and its production method

A production method and thick gauge technology, which are applied in the field of high r value thick gauge IF automotive steel and its production field, can solve the problem of no high quality IF steel product production method, etc. The effect of formability and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

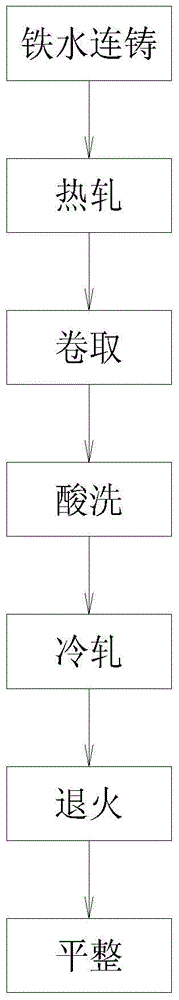

[0041] The flow process of the production method of the high r value thick specification IF automobile steel provided by the invention is:

[0042]According to the design of steel composition, C: 0.015%, Si≤0.03%, Mn: 0.11~0.15%, P≤0.015%, S≤0.012%, Als: 0.035~0.050%, N≤0.003%, and the balance is Fe And unavoidable impurities, using molten iron desulfurization, converter blowing, RH vacuum refining, continuous casting to obtain continuous casting slabs.

[0043] The continuous casting slab is heated by a heating furnace, rolled on a continuous hot rolling mill, cooled under control, and then coiled. The coiling temperature after hot rolling is controlled at 716°C to produce qualified hot-rolled steel coils. The product thickness is controlled at 2.3mm.

[0044] The hot-rolled steel coil is re-coiled and pickled to wash off the oxide scale on the surface, and then cold-rolled on a cold tandem rolling mill, and the cold-rolling reduction rate is controlled to be 76.2% to obtain...

Embodiment 2

[0048] The flow process of the production method of the high r value thick specification IF automobile steel provided by the invention is:

[0049] According to the design of steel composition, C: 0.016%, Si≤0.03%, Mn: 0.11~0.15%, P≤0.015%, S≤0.012%, Als: 0.035~0.050%, N≤0.003%, and the balance is Fe And unavoidable impurities, using molten iron desulfurization, converter blowing, RH vacuum refining, continuous casting to obtain continuous casting slabs.

[0050] The continuous casting slab is heated by a heating furnace, rolled on a continuous hot rolling mill, and cooled under control, and then coiled. The coiling temperature after hot rolling is controlled at 732°C, and qualified hot-rolled steel coils are produced. The product thickness is controlled at 2.4mm.

[0051] The hot-rolled steel coil is re-coiled and pickled to wash off the oxide scale on the surface, and then cold-rolled on a cold tandem rolling mill, and the cold-rolling reduction rate is controlled to be 75....

Embodiment 3

[0055] The flow process of the production method of the high r value thick specification IF automobile steel provided by the invention is:

[0056] According to the design of steel composition, C: 0.018%, Si≤0.03%, Mn: 0.11~0.15%, P≤0.015%, S≤0.012%, Als: 0.035~0.050%, N≤0.003%, and the balance is Fe And unavoidable impurities, using molten iron desulfurization, converter blowing, RH vacuum refining, continuous casting to obtain continuous casting slabs.

[0057] The continuous casting slab is heated by a heating furnace, rolled on a continuous hot rolling mill, and cooled under control, and then coiled. The coiling temperature after hot rolling is controlled at 722°C, and qualified hot-rolled steel coils are produced. The product thickness is controlled at 2.4mm.

[0058] The hot-rolled steel coil is re-coiled and pickled to wash off the oxide scale on the surface, and then cold-rolled on a cold tandem rolling mill to control the cold-rolling reduction rate to 78.3% to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com