Method for improving stability of contracting sizes of TC4 medical U-shaped nails

A dimensional stability, TC4 technology, applied to nails, furnace types, pins, etc., can solve the problems of difficult control of surface quality and dimensional accuracy, large difference in residual stress, scratches on the surface of bars, etc., to reduce irreversible damage. The effect of destructive loss, stable necking size, and easy temperature adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The specific scheme of the heat treatment method for improving the dimensional stability of the shrinkage of TC4 medical staples in the present invention is provided in detail by the following examples.

[0047] The test material is a medical TC4 bar with a length of φ14mm and a length of 3m (for the production of medical U-shaped nails). After hot rolling, scaling, hot drawing and electric straightening, the bar is treated according to the following scheme.

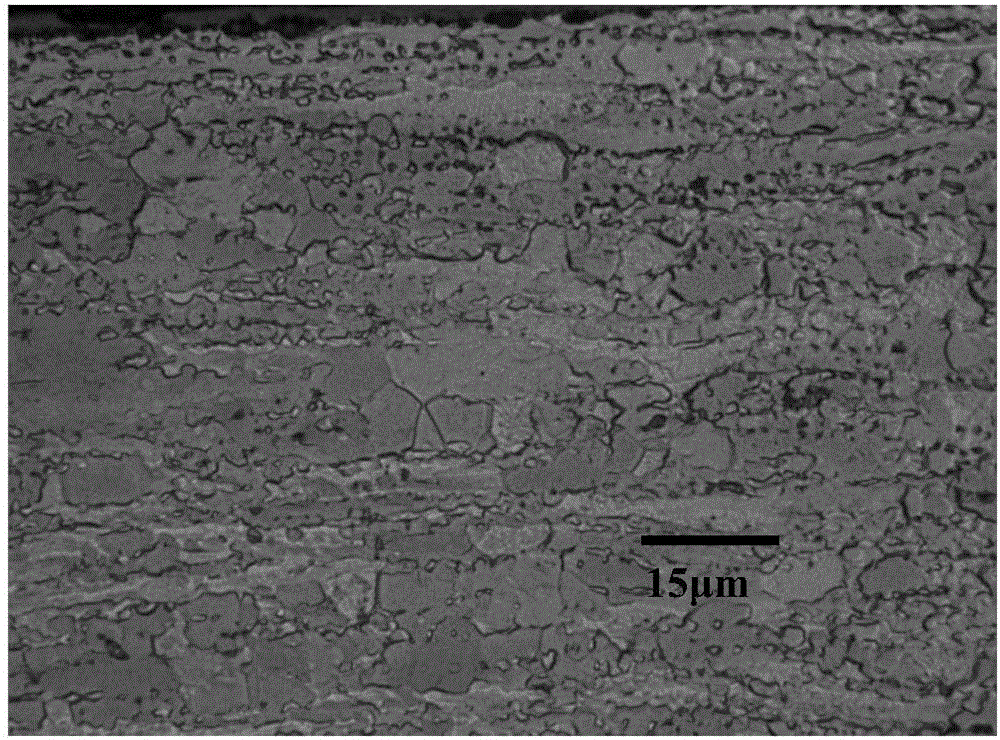

[0048] First, keep the TC4 bar in a high-temperature car bench-type resistance furnace at 710°C for 1.5h, and then air-cool it out of the furnace. Cut a 6mm section to observe the microstructure of the longitudinal section, as shown in Fig. figure 1 shown.

[0049] Then, after hyperbolic straightening of the high-temperature heat-treated bar, it was kept in a low-temperature car bench-type resistance furnace at 620°C for 1.5 hours, and then air-cooled after it was released from the furnace. A 6mm section was cut t...

Embodiment 2

[0052] First, keep the TC4 bar in a high-temperature car bench-type resistance furnace at 710°C for 1.5h, and then air-cool it out of the furnace. Cut a 6mm section to observe the microstructure of the longitudinal section, as shown in Fig. figure 1 shown.

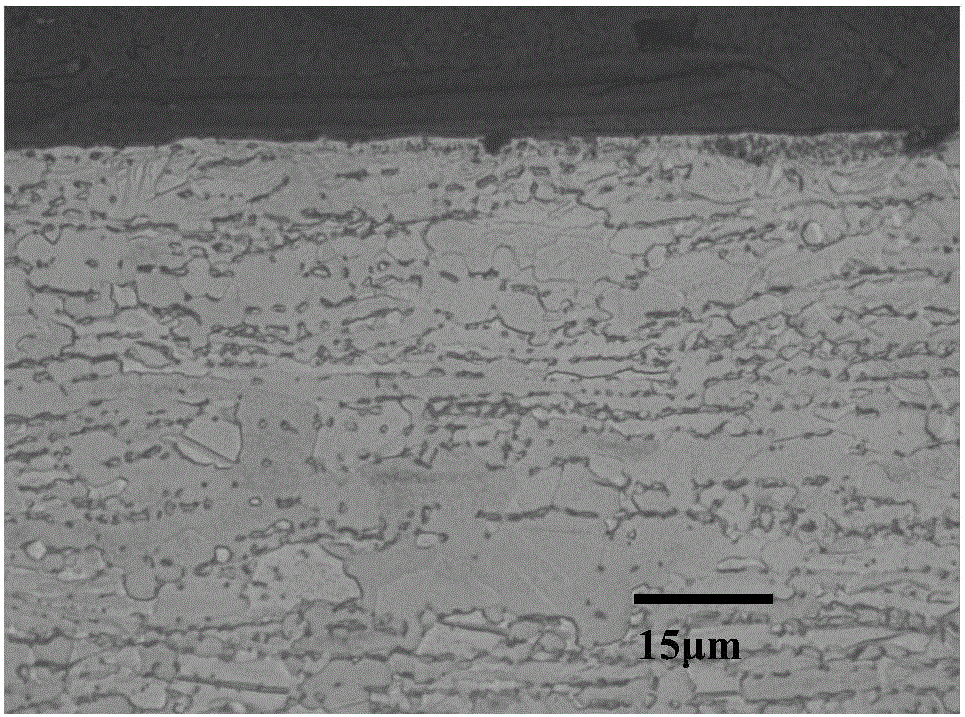

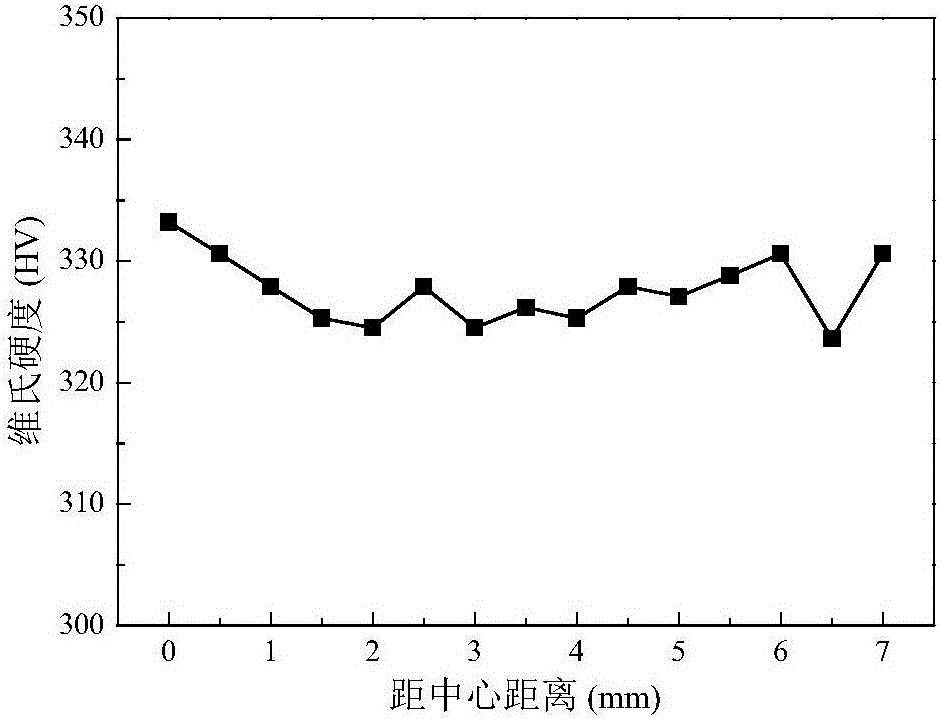

[0053] Then, after hyperbolic straightening of the high-temperature heat-treated bar, it was kept in a low-temperature car bench-type resistance furnace at 640°C for 1.5 hours, and then air-cooled after it was released from the furnace. A 6mm section was cut to observe the microstructure of the longitudinal section. The results are as follows Figure 6 shown. Use the HVS1000Z Vickers hardness tester to test the Vickers hardness of the longitudinal section. The loading load is 9.8N, the dwell time is 15s, and the hardness of 15 points is measured along the central axis of the sample from the center to the edge. The results are as follows Figure 7 shown.

[0054] Finally, after the low-temperature heat-treated bar is grou...

Embodiment 3

[0056] First, keep the TC4 bar in a high-temperature car bench-type resistance furnace at 750°C for 1.5h, and then air-cool it out of the furnace. Cut a 6mm section to observe the microstructure of the longitudinal section, as shown in Fig. Figure 10 shown.

[0057] Then, after hyperbolic straightening of the high-temperature heat-treated bar, it was kept in a low-temperature car bench-type resistance furnace at 620°C for 1.5 hours, and then air-cooled after it was released from the furnace. A 6mm section was cut to observe the microstructure of the longitudinal section. The results are as follows Figure 11 shown. Use the HVS1000Z Vickers hardness tester to test the Vickers hardness of the longitudinal section. The loading load is 9.8N, the dwell time is 15s, and the hardness of 15 points is measured along the central axis of the sample from the center to the edge. The results are as follows Figure 12 shown.

[0058] Finally, after the low-temperature heat-treated bar is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com