Method for manufacturing extra-thick plate blank by accumulative roller welding process

A technology of extra-thick slab and accumulative rolling, applied in manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of production efficiency, thickness, yield limitation, etc., and achieve the effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: Take Q235 plain carbon steel as an example.

[0023] Select two continuous casting slabs of the same size and material with a thickness of 300mm, and perform sandblasting on the surface of the surface to be laminated to remove iron scale; use compressed air to clean the surface; wipe the surface after sandblasting with acetone to remove grease, use alcohol Remove surface pollutants; use dry air at 50°C to 80°C to dry the surface; stack the superimposed surfaces of the processed two continuous casting slabs together, put them into a vacuum chamber, and place gaps around the superimposed surfaces of the continuous casting slabs Welded closed under vacuum. The welded continuous casting slab is heated to an austenite zone of 1150°C to 1250°C for heat preservation, forged or rolled, with a reduction rate of 30% at one time and a total reduction rate of 50%. A slab of 150mm thickness was obtained. The surface scanning photos of the manufactured steel plate to ...

Embodiment 2

[0024] Embodiment 2: Take Q235 plain carbon steel as an example.

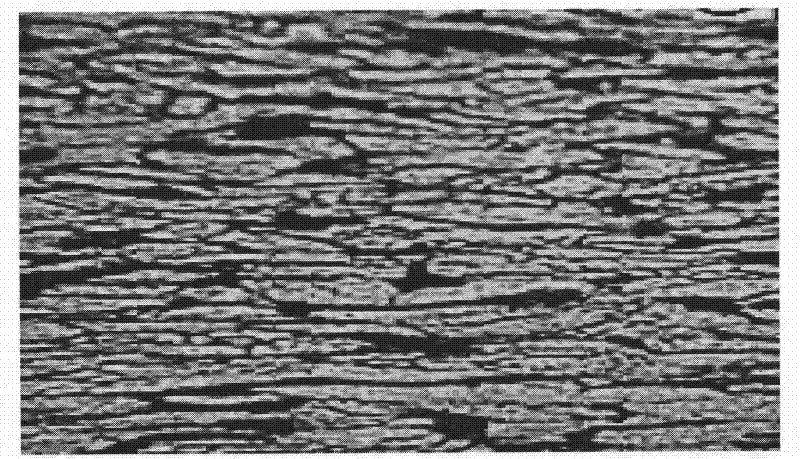

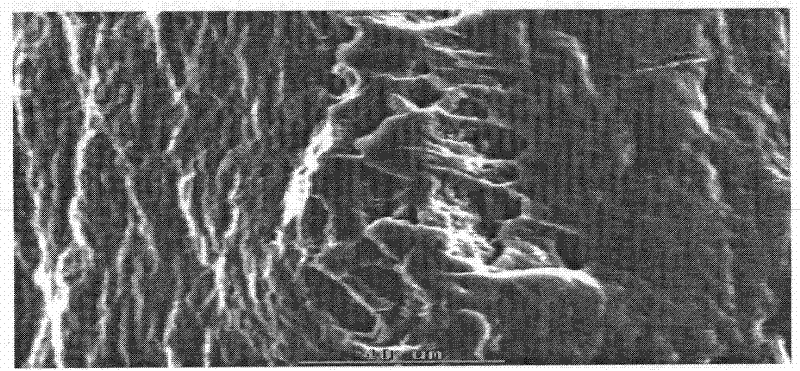

[0025] Sandblast the surface of three continuous casting slabs of the same size and material with the same thickness of 300mm to remove iron scale; use compressed air to clean the surface; use acetone to wipe the surface after sandblasting to remove grease; use alcohol to remove the surface Pollutants; use dry air at 50°C to 80°C to dry the surface; stack three continuous casting slabs together, put them in a vacuum chamber, and weld and seal the gaps around the joint surface of the continuous casting slabs under vacuum. Heat the welded continuous casting slab to the austenite zone at 1150°C to 1250°C for heat preservation, forging and forming, the first reduction rate is 30%, and the total reduction rate is 50%, to obtain a 450mm thick billet, which is then rolled by a rolling mill 200mm thick slab. Microstructure photos and transverse fracture photos of the manufactured steel plates are as follows: figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com