Accelerated aging treatment method for metal plate strip

A technology for metal strips and treatment methods, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of incomparable aging treatment performance, poor performance, low peak current density of pulse current, etc., achieve excellent comprehensive mechanical properties, improve The effect of high strength and conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

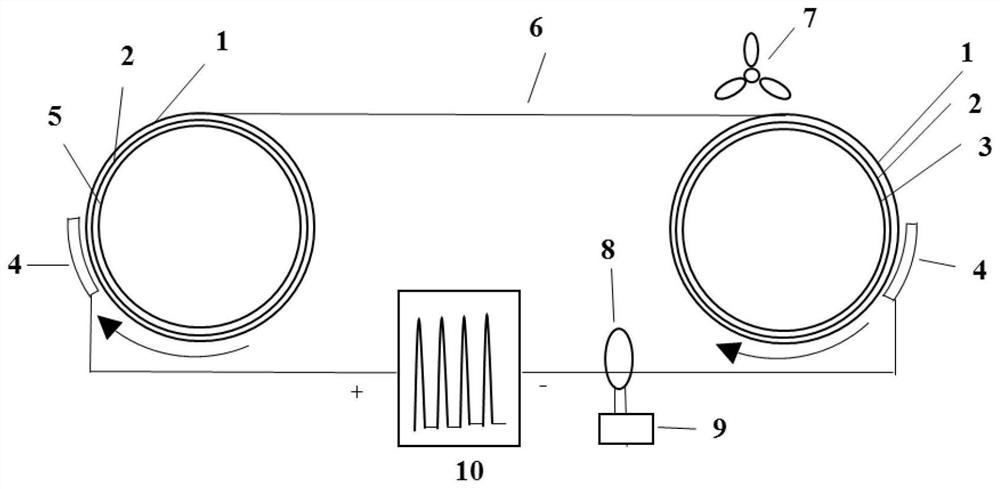

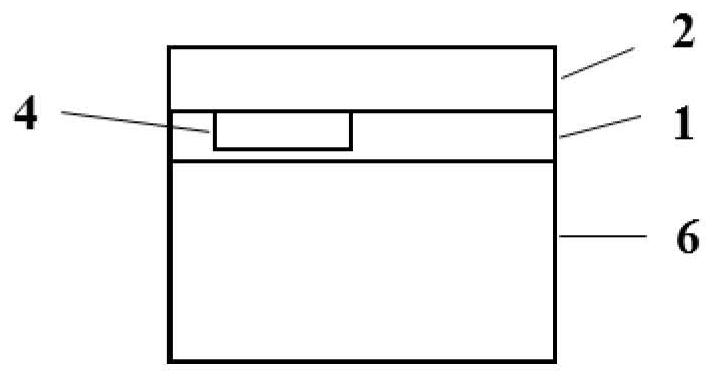

Embodiment 1

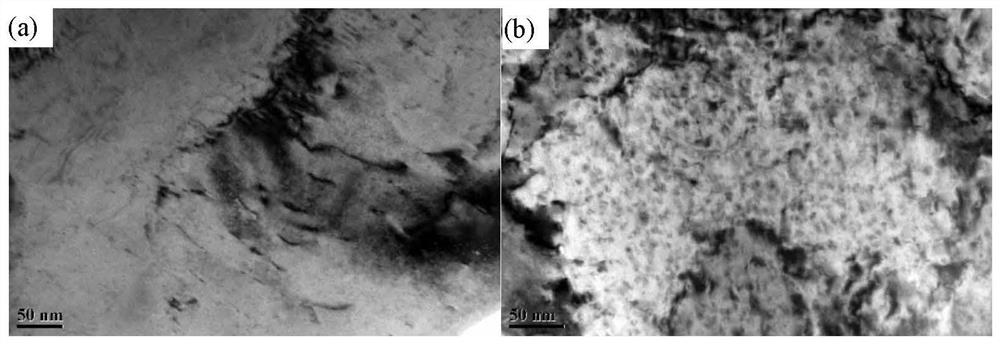

[0038] The hot-rolled C7025 copper alloy with a thickness of 14mm is cold-rolled to 0.25mm, and the pulse current treatment is performed by the device shown in the figure. The pulse width is 80μs, the treatment frequency is 600Hz, and the peak current density is 640A / mm 2 , the root mean square current density is 80A / mm 2, The passing time of the positive and negative electrodes is 15s, and 1-2nm Ni is obtained in the tissue after pulse current treatment. 2 Si precipitated phase, the strength and electrical conductivity of the obtained metal plate and strip have been improved, and its tensile strength reaches 750MPa, hardness 240HV 0.2 , The elongation rate is 10%, and the conductivity is 46% IACS.

[0039] Microstructure of Cu-Ni-Si before and after pulse current aging, see image 3 As shown, a large number of precipitated phases appeared after pulse current treatment. Compared with the traditional aging treatment of C7025 at 450℃ for 4h, the tensile strength of this mater...

Embodiment 2

[0041] The hot-rolled C7025 copper alloy with a thickness of 14mm is cold-rolled to 2.8mm by 80% reduction, and pulse aging treatment is carried out by the device shown in the figure. The pulse current frequency is 600Hz, the pulse width is 80μs, and the peak current density is 800A / mm 2 , the RMS current density is 120A / mm 2, After treatment for 15s, it will be 91% cold-rolled to 0.25mm, which is the second cold-rolling. At the same time, the pulse current treatment is performed by the device as shown in the figure, that is, the second pulse current aging. The processing frequency is 600Hz, and the peak current density is 640A / mm 2 , the root mean square current density is 80A / mm 2 , processing 15s. There are 1~2nmNi in the tissue after the pulse current treatment 2 Si precipitated phase, its strength and electrical conductivity are improved, the tensile strength of the treated material reaches 821MPa, and the hardness is 253HV 0.2 , The elongation is 9%, and the conduct...

Embodiment 3

[0043] The 7075 aluminum alloy with a cold rolling deformation rate of 90% after solid solution is treated with pulse current. The specific treatment parameters and corresponding performance are shown in the table below. The optimal treatment parameters are: pulse frequency 200Hz, pulse width 80μs, peak current density is 42A / mm 2 , the RMS current density is 4.1A / mm 2 , aging treatment for 15s, the 5nm quasi-stable η′ phase exists in the treated sample structure, and the hardness of the obtained material reaches 197HV 0.2 , the hardness value is equivalent to the traditional aging method, that is, aging at 120°C for 48h.

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com