Nano barium sulfate carbon composite material and preparation method and application therefor

A technology of nano-barium sulfate and carbon composite materials, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., and can solve the problem of unrecognized cycle performance, poor electrical conductivity, and difficult to solve nano-barium sulfate Agglomeration problems and other problems can be alleviated, the effects of sulfation of the negative electrode, cost-effective advantages, and excellent charge and discharge performance can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

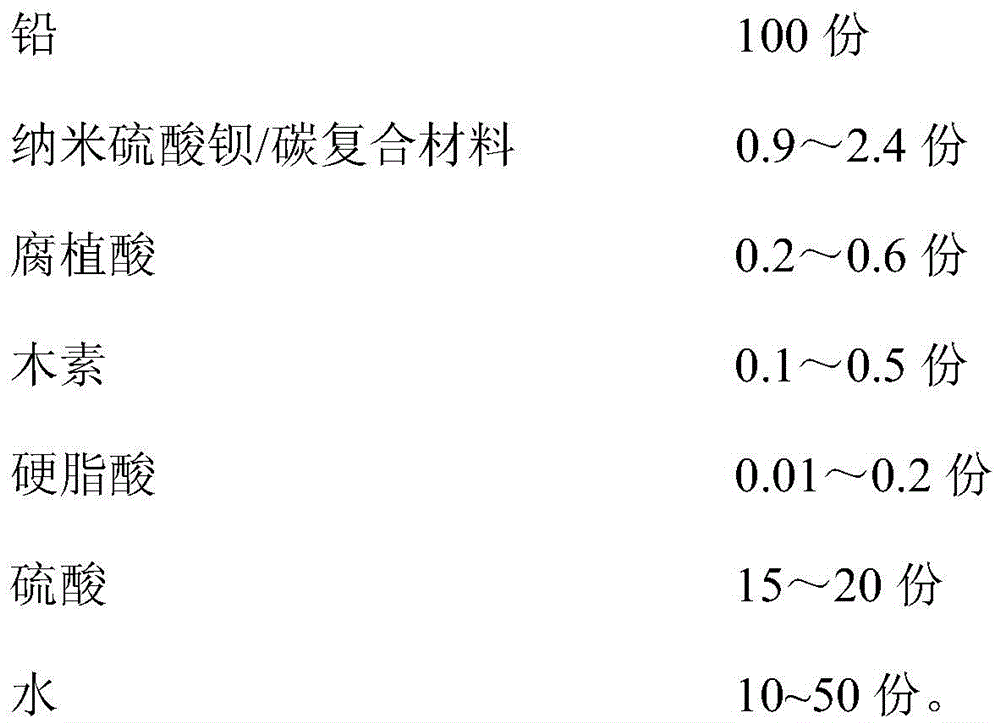

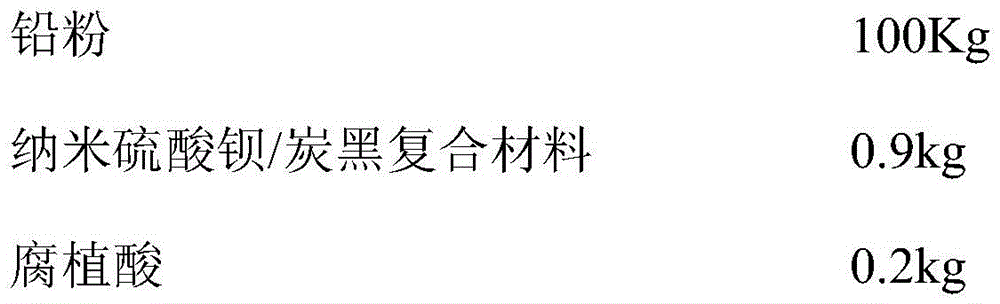

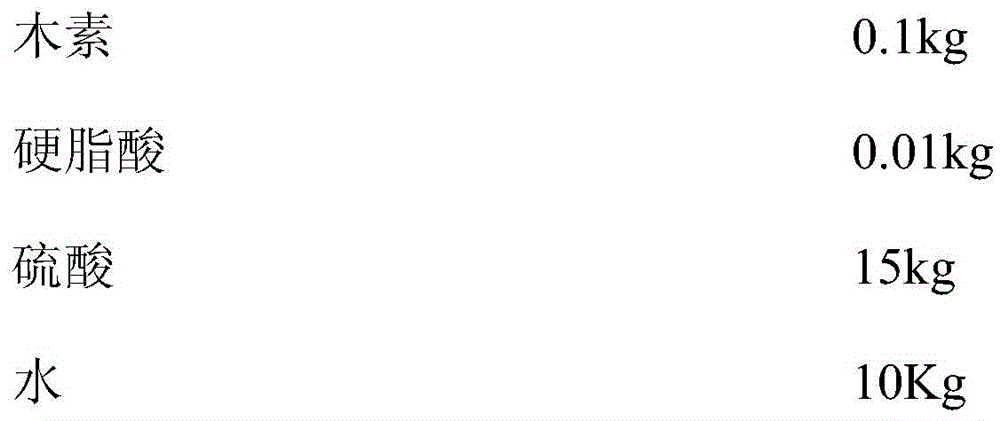

Embodiment 1

[0057] A nano-barium sulfate / carbon black composite material, which is composed of nano-barium sulfate and carbon black, and the nano-barium sulfate is dispersed on the surface of the carbon black, wherein the mass percentage of the nano-barium sulfate to the total mass of the composite material is 16.7%.

[0058] The preparation method of nano barium sulfate / carbon black composite material in the present embodiment is as follows:

[0059] Dissolve 5.9g of EDTA to 1L, the barium ion concentration is 0.1mol L -1 In the barium chloride solution, obtain solution A, adjust the pH value of solution A to 7.5; under the condition of 30 ℃, add 1L dropwise to solution A while stirring, the sulfate radical concentration is 0.1mol L -1 solution B; add 116.2g of carbon black to solution B, ultrasonically disperse for 10min, continue stirring for 0.5h, wash with water until neutral, and dry at 65°C for 2h to obtain nano barium sulfate / carbon Black composite.

[0060] The nano-barium sulf...

Embodiment 2

[0067] A nano-barium sulfate / graphite composite material is composed of nano-barium sulfate and graphite, and the nano-barium sulfate is dispersed on the surface of the graphite, wherein the mass percentage of the nano-barium sulfate to the total mass of the composite material is 28.6%.

[0068] The preparation method of nano barium sulfate / graphite composite material in the present embodiment is as follows:

[0069] Dissolve 29.2g of EDTA to 1L, the barium ion concentration is 0.2mol L -1 In the barium nitrate solution, obtain solution A, adjust the pH value of solution A to 8; under the condition of 40 ℃, add 0.2L dropwise to solution A while stirring, the sulfate radical concentration is 1mol L -1 sodium sulfate solution to obtain solution B; add 116.3g of graphite to solution B, ultrasonically disperse for 30min, continue stirring for 1h, wash with water until neutral, and dry at 70°C for 10h to obtain nano barium sulfate / graphite composite material .

[0070] The nano-b...

Embodiment 3

[0077] A nano-barium sulfate / graphene composite material is composed of nano-barium sulfate and graphene, and the nano-barium sulfate is dispersed on the surface of the graphene, wherein the mass percentage of the nano-barium sulfate to the total mass of the composite material is 33.3%.

[0078] The preparation method of nano barium sulfate / graphene composite material in the present embodiment is as follows:

[0079] Dissolve 146.1g of EDTA to 1L, the barium ion concentration is 0.5mol L -1 In the mixed solution of barium chloride and barium nitrate, solution A was obtained, and the pH value of solution A was adjusted to 7.9; at 45°C, 1 L was added dropwise to solution A while stirring, and the sulfate concentration was 0.5mol L -1 A mixed solution of potassium sulfate and sodium sulfate was obtained to obtain solution B; 233.3 g of graphene was added to solution B, ultrasonically dispersed for 40 minutes, stirred for 2 hours, washed with water until neutral, and dried at 75°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com