Method for producing Nb-containing high-speed train wheel steel

A production method and high-speed train technology, applied in the field of metal materials, can solve problems such as low impact and fracture toughness, insufficient ferrite ratio, uneven structure, etc., and achieve the goal of improving toughness, overcoming uneven structure, and refining structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The composition percentage of carbon steel in this microalloy is: C: 0.46%, Mn: 0.80%, Si: 0.40%, Cr: 0.23%, Nb: 0.03%, P: 0.006%, S: 0.0088%, and the rest The amount is Fe and unavoidable elements.

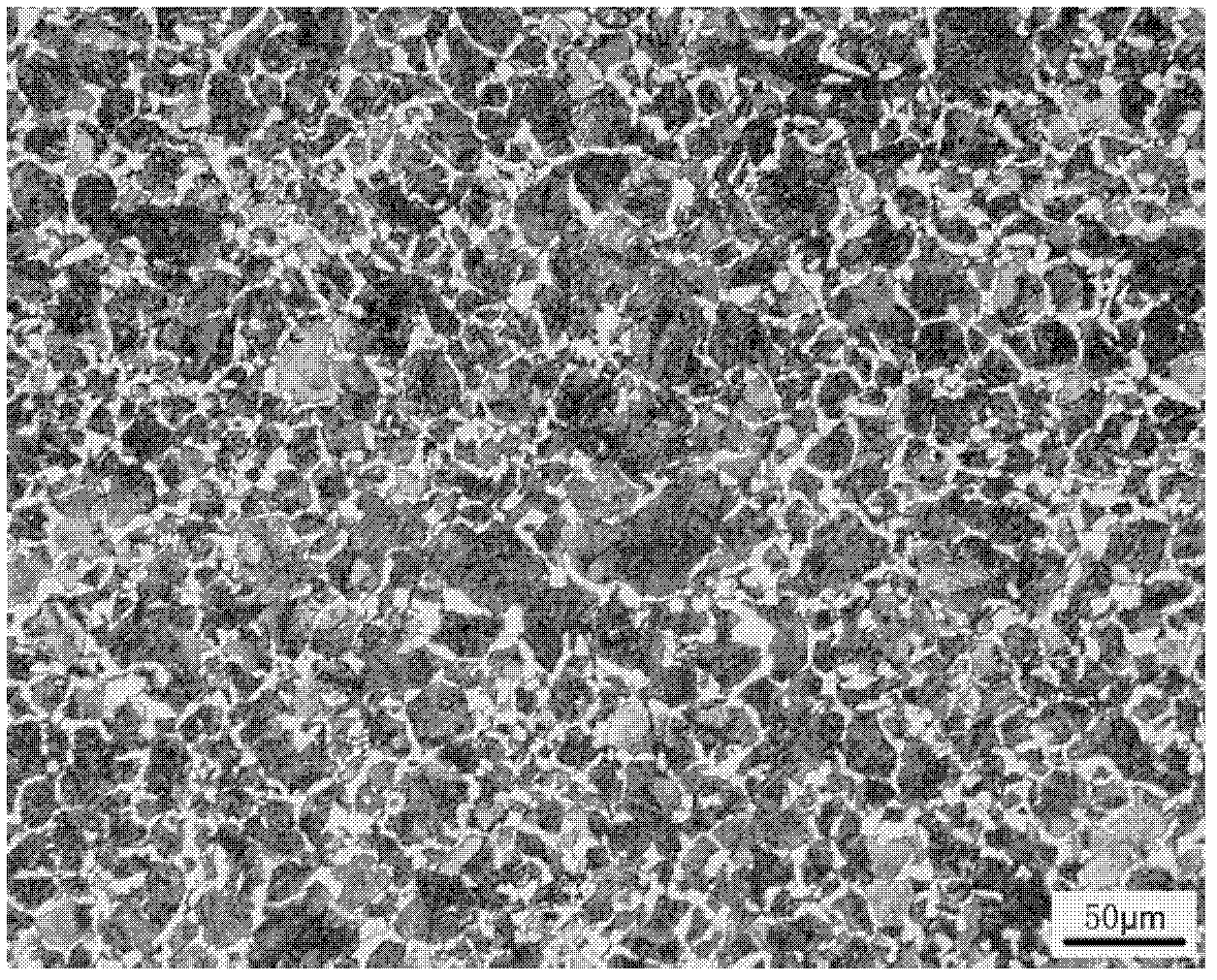

[0035]After smelting and forging, the steel is heated to 900°C, held for 1 hour to fully austenitize it, then air-cooled to room temperature, and the average cooling rate is controlled to 1°C / s through measurement and monitoring. According to the mechanical performance test, the yield strength is 450MPa, the tensile strength is 750MPa, the elongation after fracture is 23.0%, and the impact energy (Akv) at low temperature (-20°C) is 16.7J. Metallographic structure such as figure 1 As shown, the structure at room temperature is ferrite + pearlite, and the proportion of ferrite is 23%. The Nb-containing medium-carbon steel obtained under this process has a fine and uniform structure and stable performance, which can meet the testing requirements of high-speed train wheel w...

Embodiment 2

[0037] The composition percentage of carbon steel in this microalloy is: C: 0.47%, Mn: 0.80%, Si: 0.41%, Cr: 0.24%, Nb: 0.06%, P: 0.013%, S: 0.0089%, and the rest The amount is Fe and unavoidable elements.

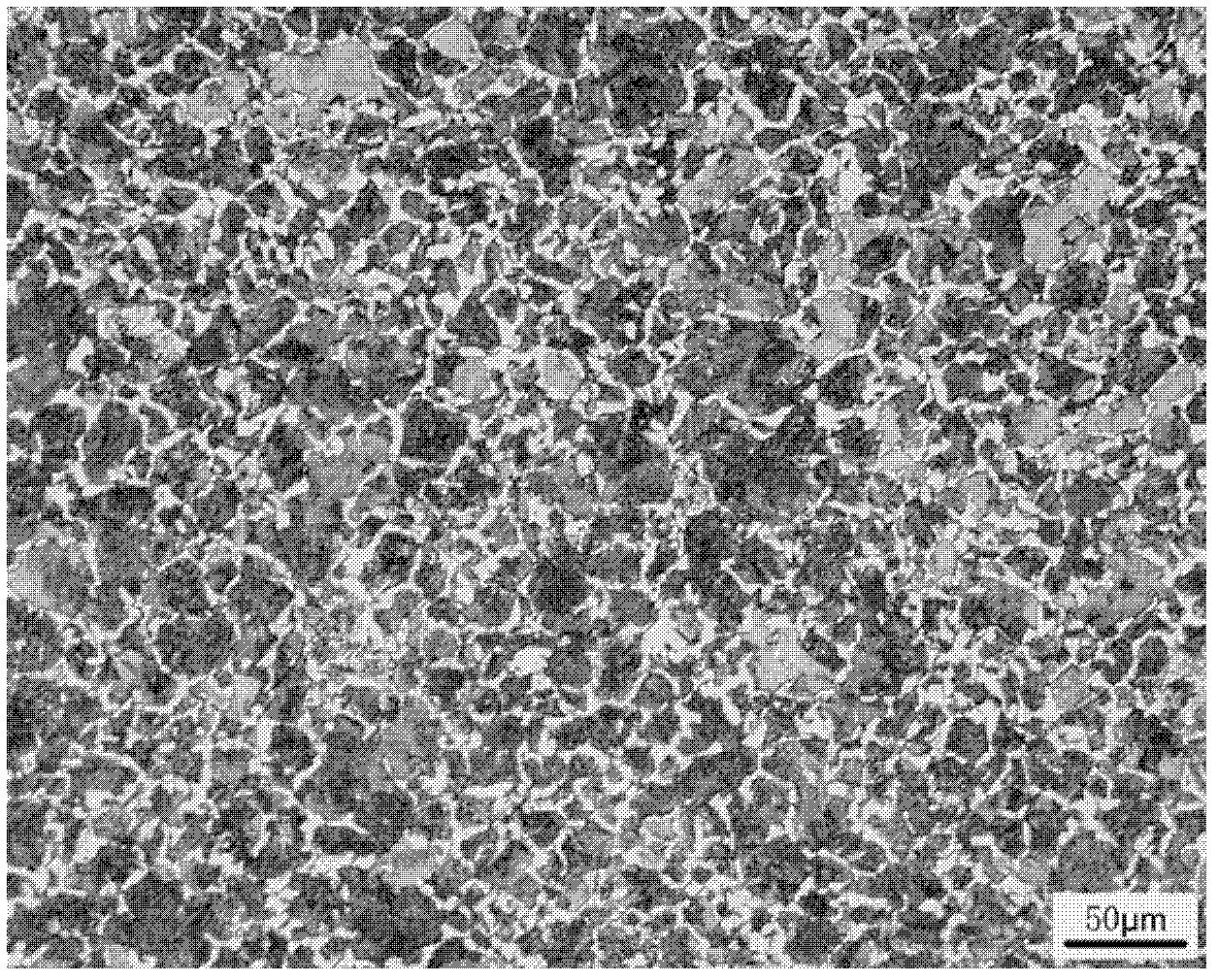

[0038] After smelting and forging, the steel is heated to 900°C, held for 1 hour to fully austenitize it, then air-cooled to room temperature, and the average cooling rate is controlled to 1°C / s through measurement and monitoring. According to the mechanical performance test, the yield strength is 455MPa, the tensile strength is 745MPa, the elongation after fracture is 22.3%, and the impact energy (Akv) at low temperature (-20°C) is 19.0J. Metallographic structure such as figure 2 As shown, the structure at room temperature is ferrite + pearlite, and the proportion of ferrite is 24%. The Nb-containing medium-carbon steel obtained under this process has a fine and uniform structure and stable performance, which can meet the testing requirements of high-speed train wheel ...

Embodiment 3

[0040] The composition percentage of carbon steel in this microalloy is: C: 0.47%, Mn: 0.80%, Si: 0.41%, Cr: 0.24%, Nb: 0.06%, P: 0.013%, S: 0.0089%, and the rest The amount is Fe and unavoidable elements.

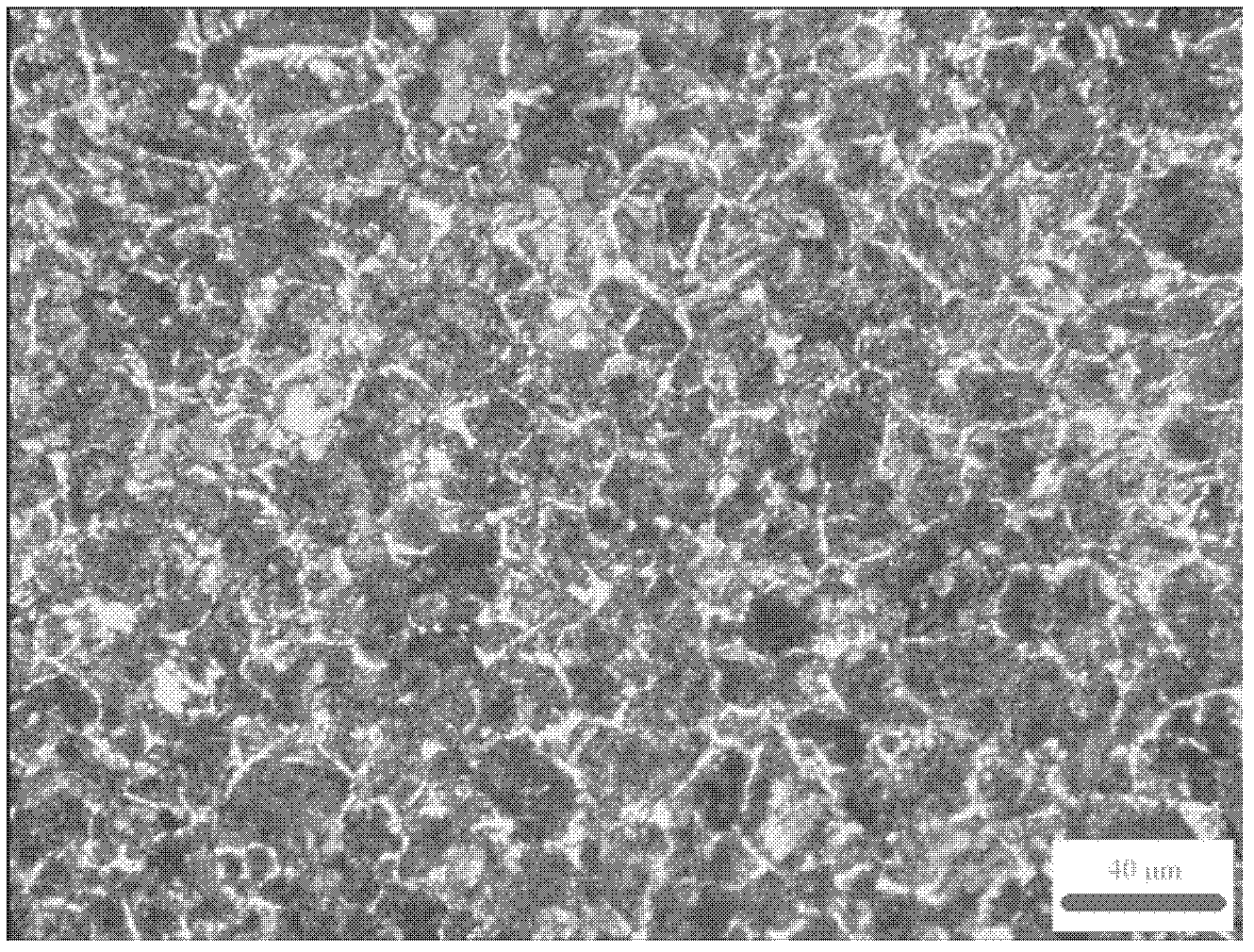

[0041] After smelting and forging, the steel is heated to 900°C, held for 1 hour to fully austenitize it, and then cooled to room temperature by spraying water, and the average cooling rate is controlled to 12°C / s through measurement and monitoring. According to the mechanical performance test, the yield strength is 530MPa, the tensile strength is 840MPa, the elongation after fracture is 21.1%, and the impact energy (Akv) at low temperature (-20°C) is 19.5J. Metallographic structure such as image 3 As shown, the structure at room temperature is ferrite + pearlite, and the proportion of ferrite is 15%. The Nb-containing medium carbon steel obtained under this process has a fine and uniform structure and stable performance, which can meet the testing requirements of high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com