TiAl alloy crystal grain refinement method

A grain refining and alloying technology, applied in the field of TiAl alloy grain refining, can solve the problems of low material utilization rate, high preparation cost, deterioration of mechanical properties of titanium-aluminum structural parts, etc., and achieves high material utilization rate and simple operation. , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment is a TiAl alloy grain refinement method.

[0034] TiAl alloys can be divided into three types according to the solidification path, including β solidification, peritectic solidification and α solidification. The solidification path of this embodiment is a peritectic solidification path, and the materials involved are Ti48Al2Cr2Nb, Ti47Al2Cr2Nb, Ti46Al2Cr2Nb and Ti(45-49)Al. In this embodiment, only Ti48Al2Cr2Nb alloy is taken as an example to describe in detail.

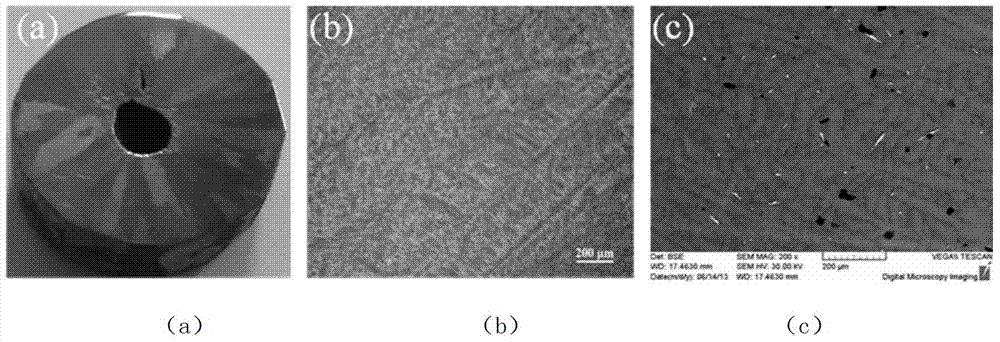

[0035] The primary phase of the Ti48Al2Cr2Nb alloy is β, and its solidification path is L→L+β→L+α→α→α+γ→α 2 +γ, the alloy undergoes a peritectic reaction during solidification, and it is easy to generate coarse columnar crystals, such as figure 1 As shown, the lamella clusters formed by the solid-state phase transition process are relatively coarse, about 3-5mm.

[0036] The concrete process of this embodiment is:

[0037] Step 1, raw material preparation. A Ti48Al2Cr2Nb alloy test bar of ...

Embodiment 2

[0043] This embodiment is a TiAl alloy grain refinement method.

[0044] TiAl alloys can be divided into three types according to the solidification path, including β solidification, peritectic solidification and α solidification. The solidification path in this embodiment is an α solidification path, and the materials involved are Ti49Al and Ti50Al. In this embodiment, only Ti50Al alloy is taken as an example to describe in detail.

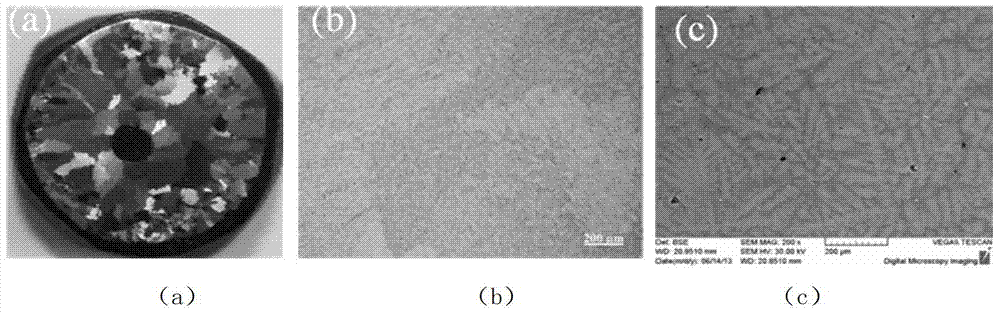

[0045] The solidification path of the Ti50Al alloy is L→L+α→α→α+γ→α 2 +γ, the alloy first forms a solid phase α when it is cooled from the liquid phase, and the α-phase crystals will preferentially grow along their c-axis, easily forming coarse columnar crystals, such as Figure 4 As shown, the lamella clusters formed during the solid-state phase transition process are relatively coarse.

[0046] The concrete process of this embodiment is:

[0047] Step 1, raw material preparation. A Ti50Al alloy test rod of Φ18×20mm was cut by wire cutting....

Embodiment 3

[0052] This embodiment is a TiAl alloy grain refinement method.

[0053] TiAl alloys can be divided into three types according to the solidification path, including β solidification, peritectic solidification and α solidification. The solidification path of this embodiment is a β solidification path, and the materials involved are high niobium titanium aluminum and titanium aluminum alloy with an aluminum content lower than 44%. In this embodiment, only Ti45Al8Nb0.2W0.2B alloy is taken as an example to describe in detail.

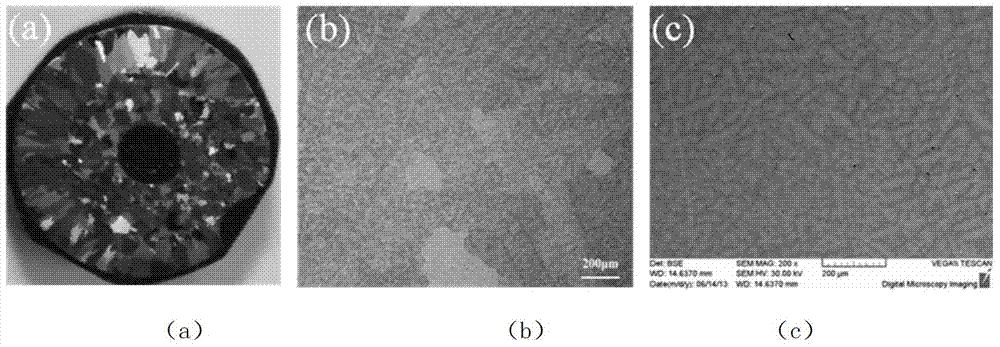

[0054] The solidification path of the Ti45Al8Nb0.2W0.2B alloy is L→L+β→β→β+α→α→α 2 +γ, because the columnar grain characteristics of the β-phase solidification structure are weak, it is easy to form relatively fine equiaxed crystals, such as Image 6 shown.

[0055] The concrete process of this embodiment is:

[0056] Step 1, raw material preparation. A Φ18×20mm Ti45Al8Nb0.2W0.2B alloy test rod was cut by wire cutting. The Ti45Al8Nb0.2W0.2B alloy test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com