High-strength and high-conductivity rare earth copper and zirconium alloy and preparation method thereof

A technology of copper-zirconium alloy and zirconium alloy, which is applied in the field of high-strength and high-conductivity rare earth copper-zirconium alloy and its preparation, can solve the problems of low strength and hardness, low tensile strength, low electrical conductivity and elongation, and improve elongation , Improve the strength and conductivity, and improve the effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

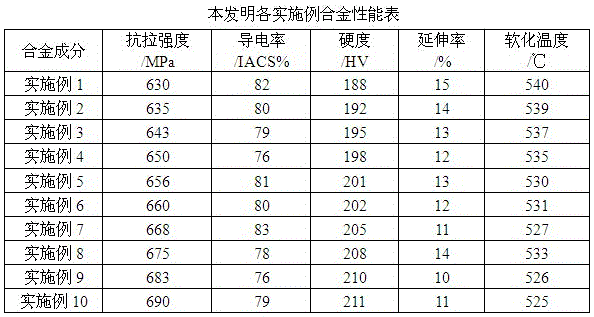

Examples

preparation example Construction

[0024] A method for preparing a high-strength and high-conductivity rare earth copper-zirconium alloy, comprising the following steps:

[0025] Step 1. Preparation of master alloy: put copper and zirconium into a vacuum non-consumable electrode arc melting furnace for melting, vacuumize the furnace until the pressure is 5×10-2Pa, and then fill the furnace with argon until the pressure in the furnace is 0.05 MPa, heated to 1050~1100℃, smelted for 0.5~1h, and obtained Cu-Zr master alloy after natural cooling, for later use; put copper and rare earth elements into a vacuum non-consumable electrode arc melting furnace for melting, and vacuumize the furnace The internal pressure is 5×10-2Pa, then fill the furnace with argon until the pressure in the furnace is 0.05MPa, heat to 1030~1070°C, melt for 0.5~1h, and naturally cool to obtain Cu-rare earth master alloy for later use; Put it into a vacuum non-consumable electrode arc melting furnace for melting, evacuate to a pressure of 5×...

Embodiment 1

[0037]A high-strength and high-conductivity rare earth copper-zirconium alloy is composed of the following components by weight percentage: 0.1% zirconium, 0.1% nickel, 0.1% silicon, 0.1% silver, 0.05% cerium, and the balance is copper.

[0038] The specific preparation method is:

[0039] Step 1. Preparation of master alloy: put copper and zirconium in a vacuum non-consumable electrode arc melting furnace for melting, and vacuumize until the pressure in the furnace is 5×10 -2 Pa, then filled with argon until the pressure in the furnace is 0.05MPa, heated to 1050°C, smelted for 1h, and cooled naturally to obtain a Cu-Zr master alloy for later use; put copper and rare earth into a vacuum non-consumable electrode arc melting furnace Smelting in the furnace, vacuuming until the pressure in the furnace is 5×10 -2 Pa, then filled with argon until the pressure in the furnace is 0.05MPa, heated to 1030°C, smelted for 0.5h, and cooled naturally to obtain a Cu-rare earth master alloy ...

Embodiment 2

[0047] A high-strength and high-conductivity rare earth copper-zirconium alloy is composed of the following components in weight percentage: 0.15% zirconium, 0.15% nickel, 0.1% silicon, 0.15% silver, 0.05% lanthanum, and the balance is copper.

[0048] The specific preparation method is:

[0049] Step 1. Preparation of master alloy: put copper and zirconium in a vacuum non-consumable electrode arc melting furnace for melting, and vacuumize until the pressure in the furnace is 5×10 -2 Pa, then filled with argon until the pressure in the furnace is 0.05MPa, heated to 1080°C, smelted for 1h, and cooled naturally to obtain a Cu-Zr master alloy for later use; put copper and rare earth into a vacuum non-consumable electrode arc melting furnace Smelting in the furnace, vacuuming until the pressure in the furnace is 5×10 -2 Pa, then filled with argon until the pressure in the furnace is 0.05MPa, heated to 1030°C, smelted for 0.5h, and cooled naturally to obtain a Cu-rare earth master...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com