Method for depositing perovskite film on hydrophobic hole transport layer

A technology of hole transport layer and perovskite, which is applied in the direction of electrical components, circuits, electric solid devices, etc., can solve the problems of deteriorating luminescent properties, poor compatibility, unfavorable perovskite crystallization and film formation, etc., and achieve improved fluorescence production The effect of high efficiency, wettability improvement, high quality and rapid preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

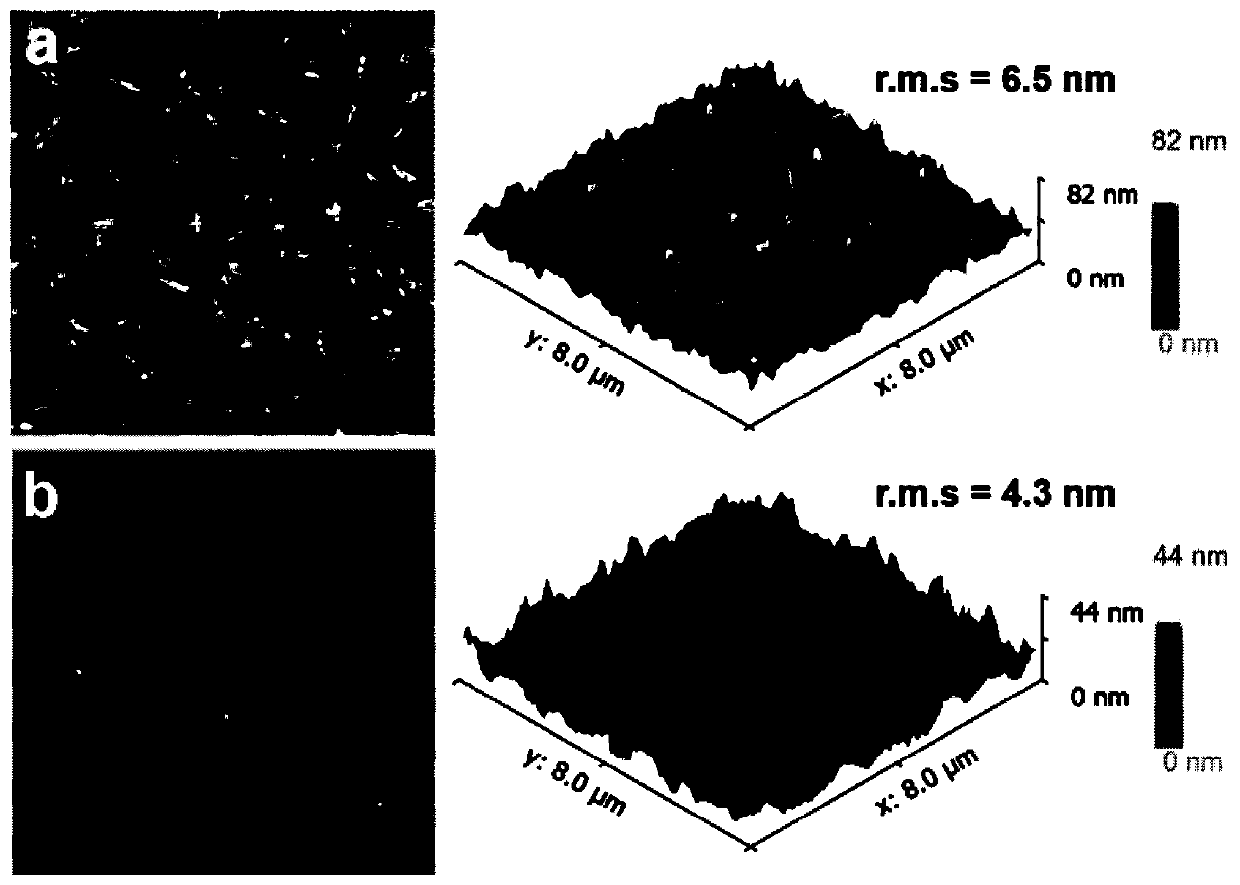

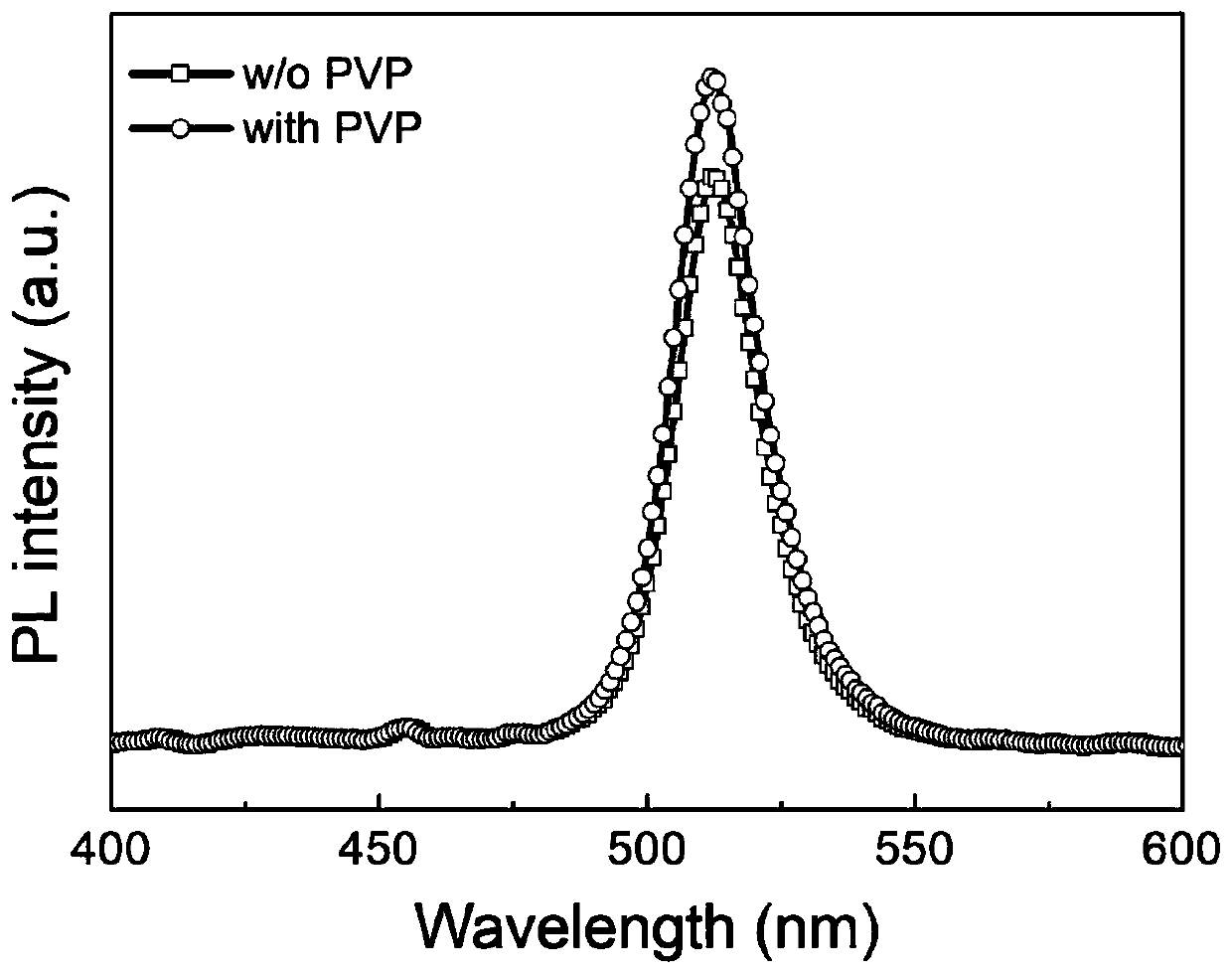

[0028] Below in conjunction with specific implementation example, above-mentioned scheme is described further, and preferred embodiment of the present invention is described in detail as follows:

[0029] In this embodiment, a method for depositing a perovskite film on a hydrophobic hole transport layer comprises the following steps:

[0030] a. Preparation of hole transport layer solution:

[0031] Using poly(9,9-dioctylfluorene-CO-N-(4-butylphenyl) diphenylamine) (TFB) and polyvinylcarbazole (PVK) as raw materials, weigh the quality of PVK and TFB respectively 6 and 4 mg, dissolved in 1ml of chlorobenzene solvent to obtain a raw material mixture, use a stirrer to stir the raw material mixture for 2 hours, and then use a 0.45 μm polytetrafluoroethylene filter to filter the raw material mixture to obtain a uniform mixture PVK:TFB solution, spare;

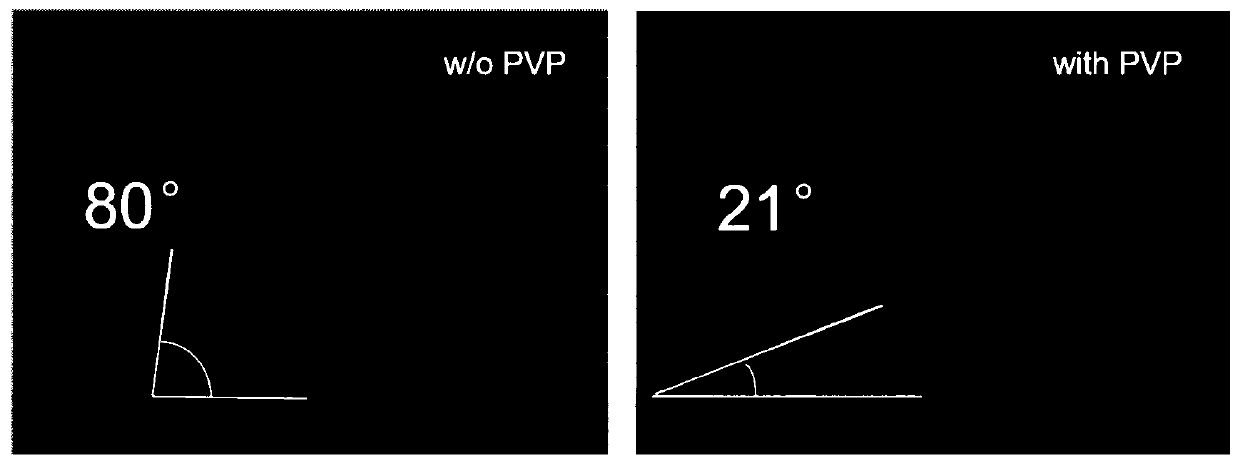

[0032] b. Preparation of PVP solution:

[0033] Dissolve PVP in absolute ethanol so that the concentration of PVP is 1.5 mg / ml,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com