Novel deposition method for si-ge epi layer on different intermediate substrates

a technology of sige epi layer and intermediate substrate, which is applied in the direction of basic electric elements, electrical apparatus, semiconductor devices, etc., to achieve the effect of increasing nucleation sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

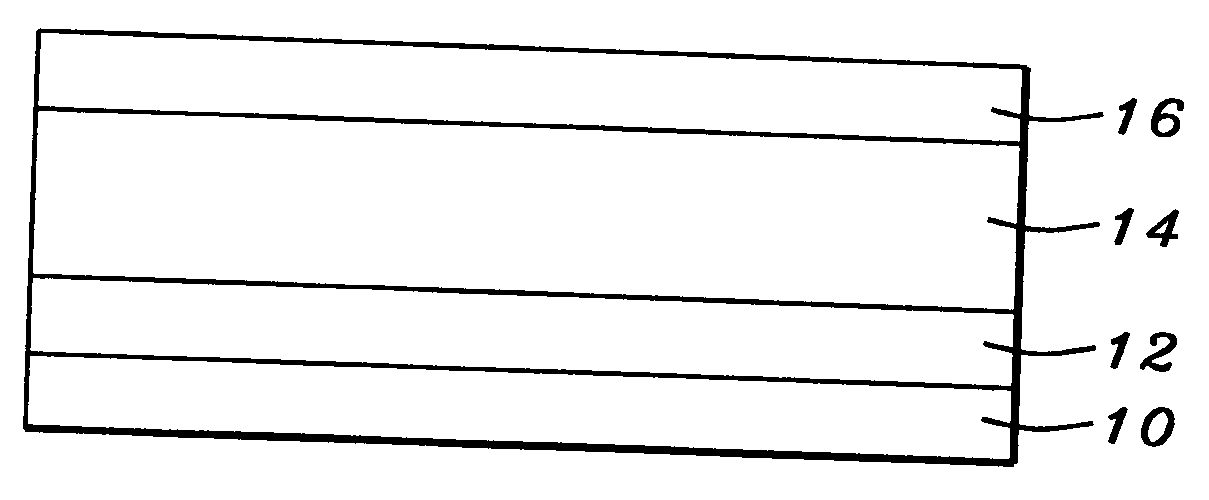

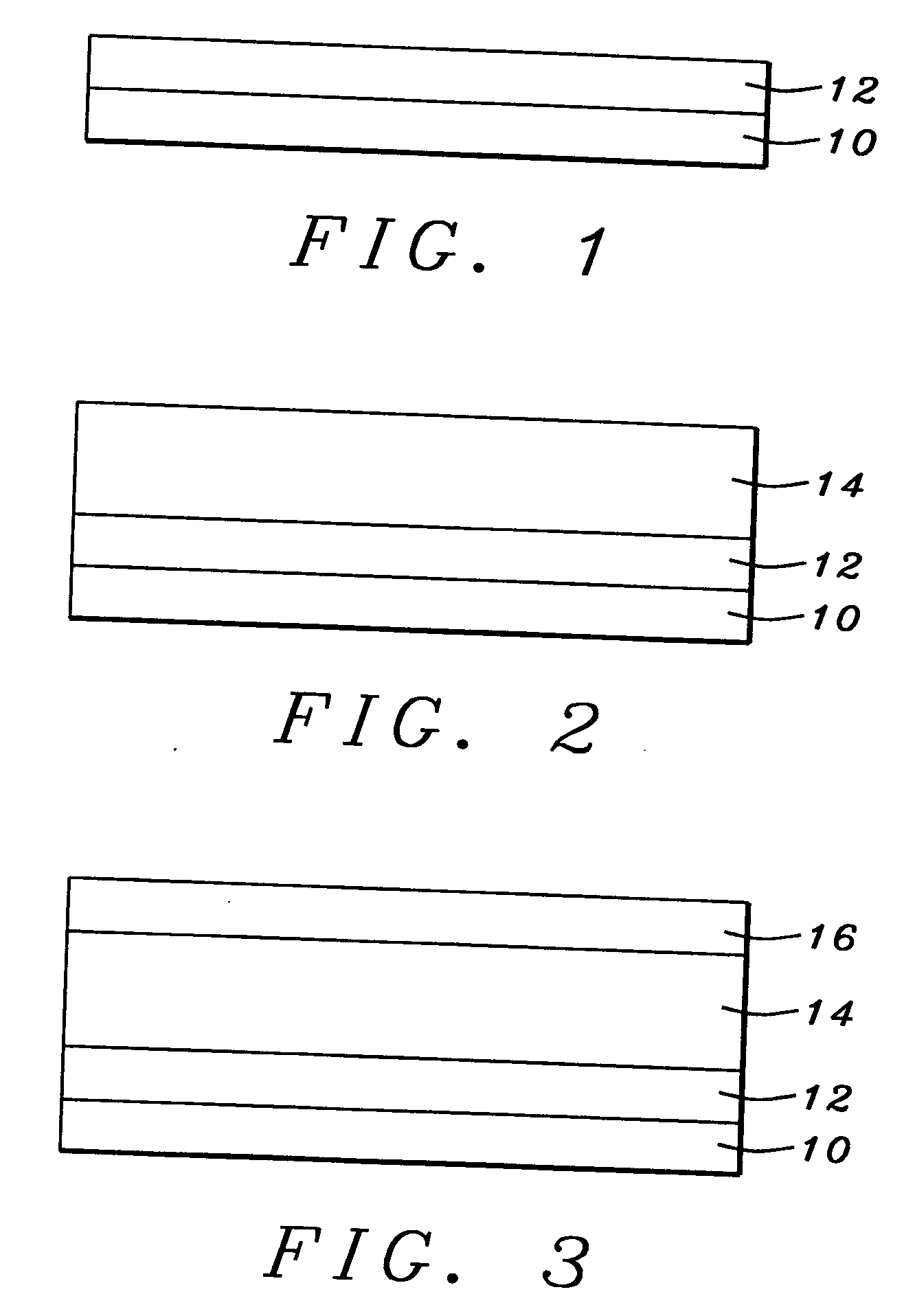

Initial Structure—FIG. 1

[0012] As shown in FIG. 1, structure 10 has a seed layer 12 formed thereover. Structure 10 is preferably an intermediate substrate and may be a silicon substrate and is understood to possibly include a semiconductor wafer or substrate, active and passive devices formed within the wafer, conductive layers and dielectric layers (e.g., inter-poly oxide (IPO), intermetal dielectric (IMD), etc.) formed over the wafer surface. The term “semiconductor structure” is meant to include devices formed within a semiconductor wafer and the layers overlying the wafer. Structure 10 may also include silicon oxide and / or polysilicon.

[0013] Seed layer 12 is preferably a doped Si—Ge layer having a thickness of preferably from about 10 to 400 Å and more preferably from about 20 to 200 Å. Doped Si—Ge seed layer 12 is preferably doped with boron (B), C, P or As and is more preferably doped with boron (B).

[0014] When doping with boron, B2H6 is introduced during the formation of S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com