Hydrogen-corrosion-resistant normalized low-alloy steel for mobile tanker and preparation method of hydrogen-corrosion-resistant normalized low-alloy steel

A low-alloy steel and mobile tank technology, which is applied in the field of high-strength, high-toughness hydrogen corrosion-resistant steel and its preparation, can solve problems such as poor low-temperature impact toughness, poor hydrogen corrosion resistance, and high yield ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

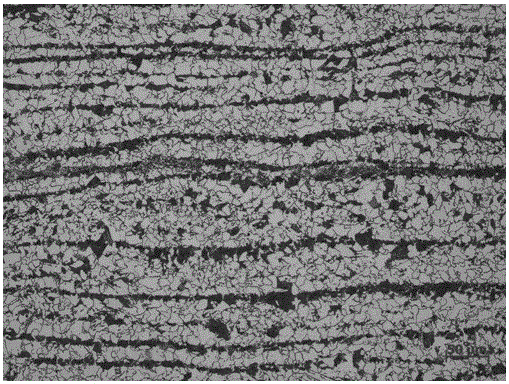

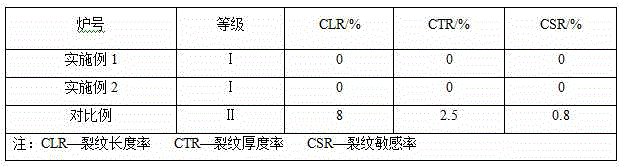

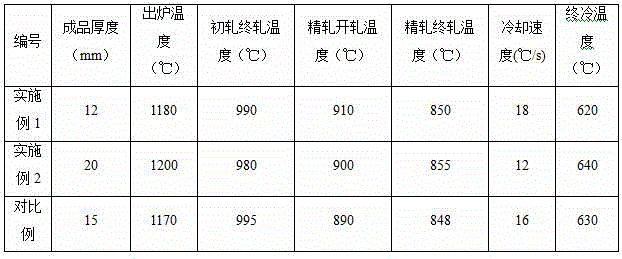

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0028] The chemical composition of the steel plate in the embodiment of the present invention satisfies: C: 0.13-0.20%, Si: 0.20-0.50%, Mn: 1.20-1.70%, P≤0.030%, S≤0.010%, Ni: 0.10-0.45%, Nb : 0.010~0.050%, V: 0.010~0.20%, 30ppm≤N≤50ppm, H≤2ppm, 8≤ w (V) / w (N) ≤ 15, the balance is Fe and unavoidable impurities.

[0029] The chemical compositions of specific examples and comparative examples are shown in Table 1.

[0030] Table 1 embodiment and comparative example chemical composition (wt%)

[0031]

[0032]The steel plate preparation process includes: molten iron pretreatment, converter steelmaking, RH vacuum degassing treatment after LF refining, and protective casting into a 150mm thick cast slab. Heat the slab with a thickness of 150mm to 1140-1240°C, and the furnace time is slab thickness (cm)×8-12min / cm. Then adopt two-stage roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com