High-strength and low-yield ratio easy-to-weld movable pressure vessel steel plate and manufacturing method thereof

A technology with low yield ratio and moving pressure, which is applied in the field of thin-gauge, high-strength, thin-gauge, low-yield ratio, and high-toughness steel plates. It can solve the problems of poor welding ability and high yield ratio, and achieve excellent performance, short production cycle and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

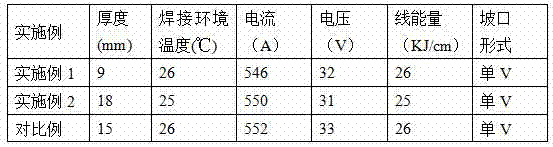

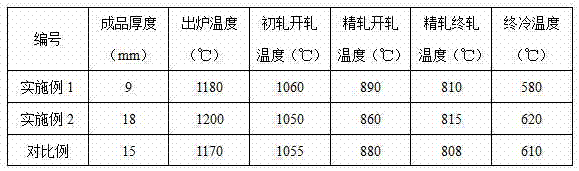

[0029] Below in conjunction with embodiment the present invention is described in further detail.

[0030] The chemical composition (by weight percentage) of the specific embodiment of the present invention is C: 0.14-0.20%, Si: 0.20-0.60%, Mn: 1.10-1.70%, P≤0.020%, S≤0.010%, Ni: 0.20~ 0.80%, Nb: 0.010~0.050%, V: 0.010~0.20%, 40ppm≤N≤80ppm, H≤2ppm, Pcm≤0.30, the balance is Fe and unavoidable impurities.

[0031] Embodiment of the present invention and comparative example chemical composition are shown in Table 1

[0032] Table 1 Chemical composition (wt%) of embodiment and comparative example

[0033] Numbering

C

Si

mn

P

S

Ni

Nb

V

N

H

Pcm

Example 1

0.18

0.28

1.52

0.007

0.001

0.55

0.020

0.120

0.0060

0.0001

0.286

Example 2

0.17

0.25

1.55

0.005

0.002

0.57

0.018

0.110

0.0070

0.0001

0.276

comparative example

0.15

0.38

1.48

0.015

0.01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com