Stirring type preparation process of stirring type active probiotic flavored fermented milk

A technology of active probiotics and preparation process, which is applied in the field of preparation of stirred-type active probiotic flavored fermented milk, can solve the problems of small number of probiotics and single function, achieve high efficiency, promote cell growth, and promote calcium absorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

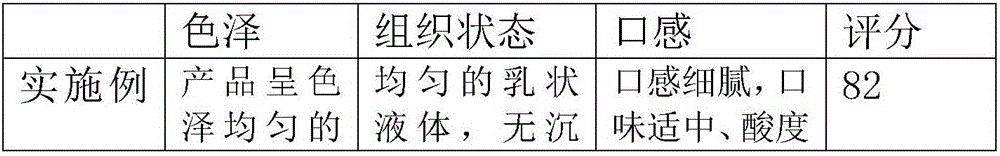

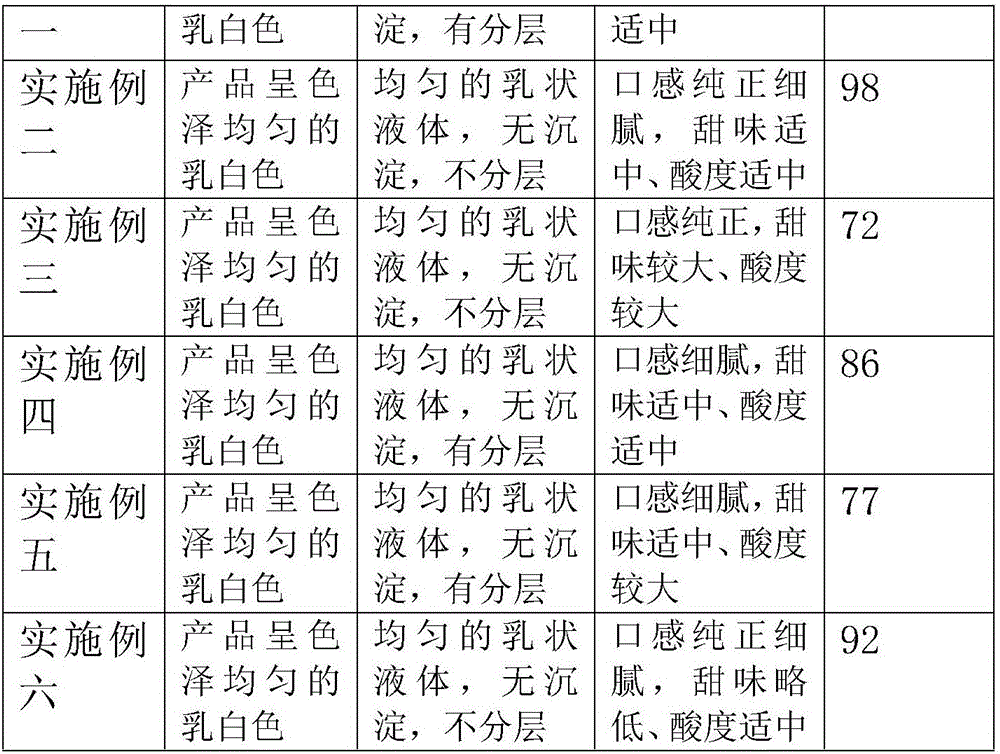

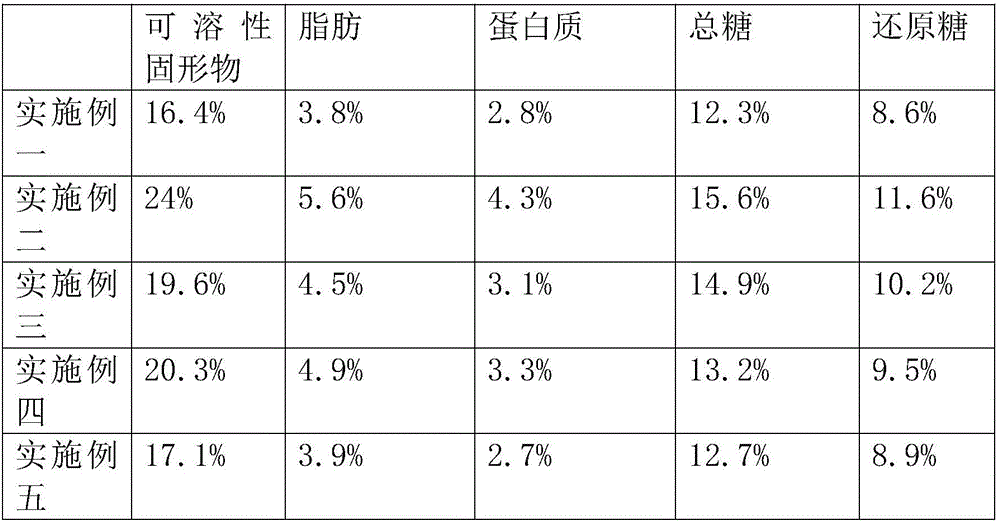

Examples

Embodiment 1

[0037] This example provides a preparation process for agitated active probiotic-flavored fermented milk, including raw materials and strains. The raw materials are made of the following materials in parts by weight: 83 parts of raw milk, 2 parts of white sugar, whey protein 0.15 parts of powder, 0.15 parts of isomaltooligosaccharide, 2 parts of barley syrup, 0.25 parts of compound stabilizer, 0.07 parts of anhydrous butter, 0.02 parts of sucralose, the strains include Streptococcus thermophilus, Lactobacillus bulgaricus, plant Lactobacillus and Lactobacillus rhamnosus, the preparation process is as follows:

[0038] 1) Raw milk inspection, clean milk, standardization, temporary storage;

[0039] 2) Heat raw milk to 65°C, then heat white sugar, whey protein powder, isomalto-oligosaccharide, barley syrup, compound stabilizer, anhydrous butter, and sucralose to 65°C and add to raw milk, Obtain mixed milk under high pressure homogenization at 20MPa;

[0040] 3) Warm up the mixe...

Embodiment 2

[0059] This example provides a preparation process for stirring active probiotic-flavored fermented milk, including raw materials and strains. The raw materials are made of the following materials in parts by weight: 85 parts of raw milk, 2.5 parts of white sugar, whey protein 0.2 parts of powder, 0.2 parts of isomaltooligosaccharide, 2.5 parts of barley syrup, 0.32 parts of compound stabilizer, 0.1 part of anhydrous butter, 0.03 parts of sucralose, and the strains include Streptococcus thermophilus, Lactobacillus bulgaricus, plant Lactobacillus and Lactobacillus rhamnosus, the preparation process is as follows:

[0060] 1) Raw milk inspection, clean milk, standardization, temporary storage;

[0061] 2) Heat raw milk to 65°C, then heat white sugar, whey protein powder, isomalto-oligosaccharide, barley syrup, compound stabilizer, anhydrous butter, and sucralose to 65°C and add to raw milk, Obtain mixed milk under high pressure homogenization at 20MPa;

[0062] 3) Warm up the ...

Embodiment 3

[0081] This example provides a preparation process for stirring active probiotic-flavored fermented milk, including raw materials and strains. The raw materials are made of the following materials in parts by weight: 87 parts of raw milk, 3 parts of white sugar, whey protein 0.25 parts of powder, 0.25 parts of isomaltooligosaccharide, 3 parts of barley syrup, 0.4 parts of compound stabilizer, 0.12 parts of anhydrous butter, 0.04 parts of sucralose, and the strains include Streptococcus thermophilus, Lactobacillus bulgaricus, plant Lactobacillus and Lactobacillus rhamnosus, the preparation process is as follows:

[0082] 1) Raw milk inspection, clean milk, standardization, temporary storage;

[0083] 2) Heat raw milk to 65°C, then heat white sugar, whey protein powder, isomalto-oligosaccharide, barley syrup, compound stabilizer, anhydrous butter, and sucralose to 65°C and add to raw milk, Obtain mixed milk under high pressure homogenization at 20MPa;

[0084] 3) Warm up the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com