Biomass feed extruder

An extruder, biomass technology, applied in feed, food science, application and other directions, can solve the problems of feeding rollers, hob, cutter easy to wear, uneven and stable feeding speed, reduce production efficiency and other problems, and achieve the puffing effect. Good, moderate advancing speed, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

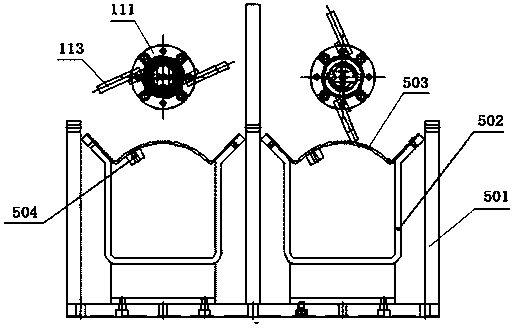

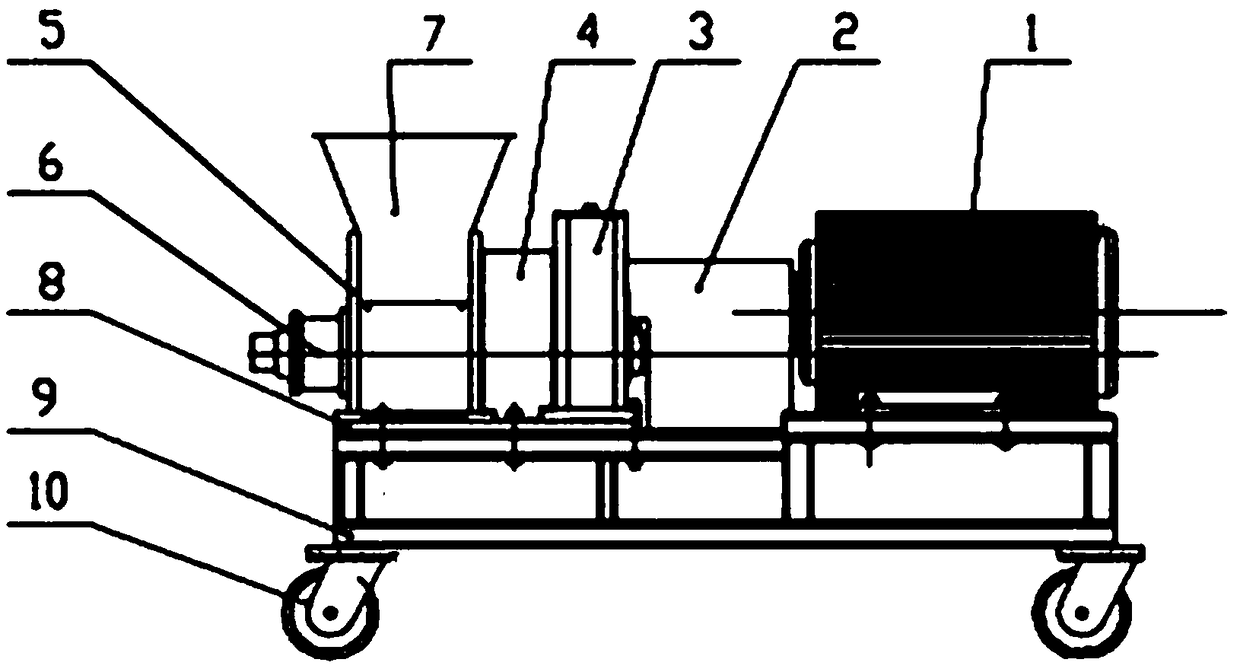

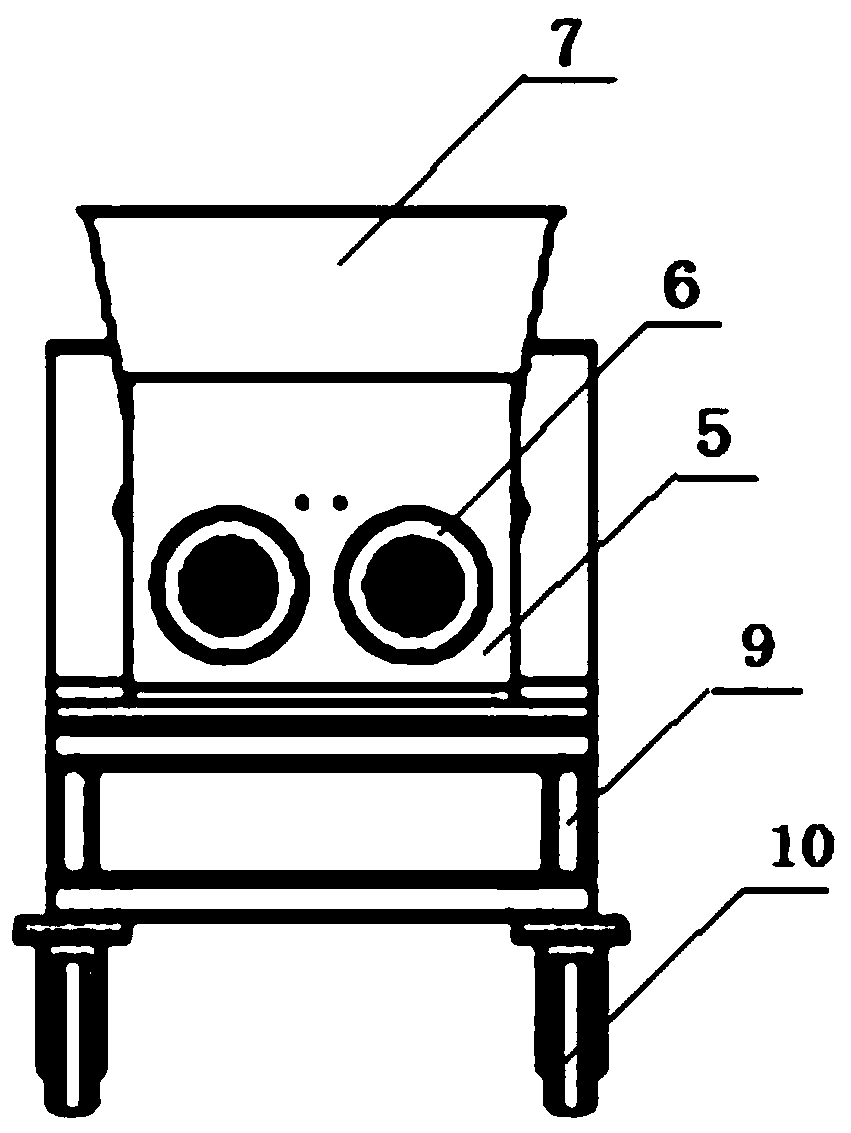

[0033] Such as figure 1 , 2 As shown, the biomass feed extruder of the present invention includes a power source 1, a first protective cover 2, a transmission mechanism 3, a second protective cover 4, an expansion tank assembly 5, an expansion propeller assembly 6, and a hopper weldment 7 , gearbox connecting plate 8, frame welding assembly 9, casters 10. The power source 1 is installed and fixed on the frame welding assembly 9 through bolts; the transmission mechanism 3 and the expansion box assembly 5 are installed and fixed on the frame welding assembly 9 through the gearbox connecting plate 8; the expansion propeller assembly Part of the 6 is located in the expansion tank assembly 5, and the other part is located in front of the expansion tank assembly 5, and the hopper welding part 7 is installed above the expansion tank assembly 5; multiple casters 10 are installed on the frame welding assembly 9; the first protective cover 2 is installed at the joint of the power sour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com