A method for preparing titanium-based spherical powder with fine particle size by gas atomization

A spherical powder, gas atomization technology, applied in the field of powder metallurgy, can solve the problem of high technical requirements, achieve the effect of improving the yield of fine powder, high yield of fine powder, and improving the problem of hollow ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The method of this embodiment is:

[0027] Step 1. Put the Ti6Al4V alloy ingot and tin block into a water-cooled copper crucible, and then place it in the melting chamber of the vacuum induction melting gas atomization equipment, and evacuate the melting chamber until the vacuum degree in the furnace is not greater than 5Pa. Vacuum induction melting is carried out at a temperature of 1700°C; the amount of the tin material is 2% of the total mass of the titanium alloy raw material and the tin material;

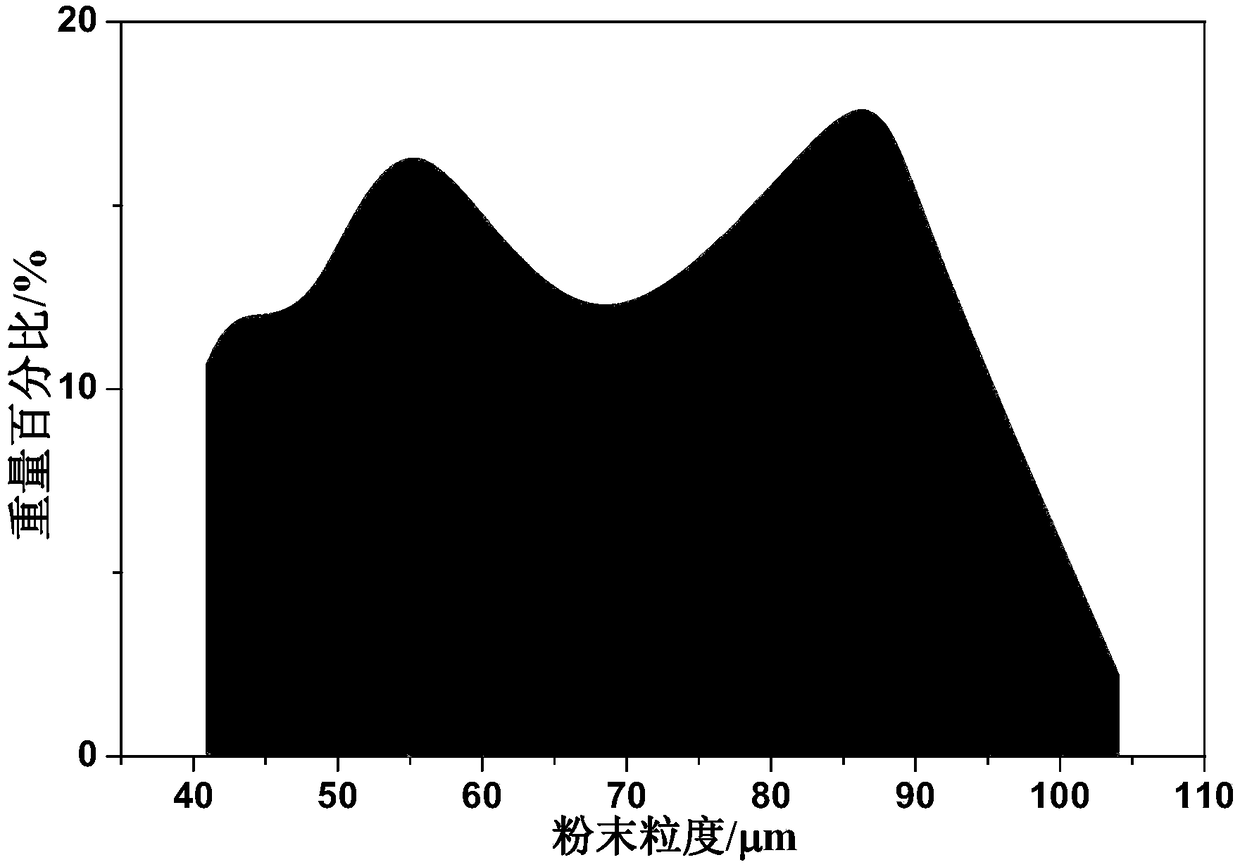

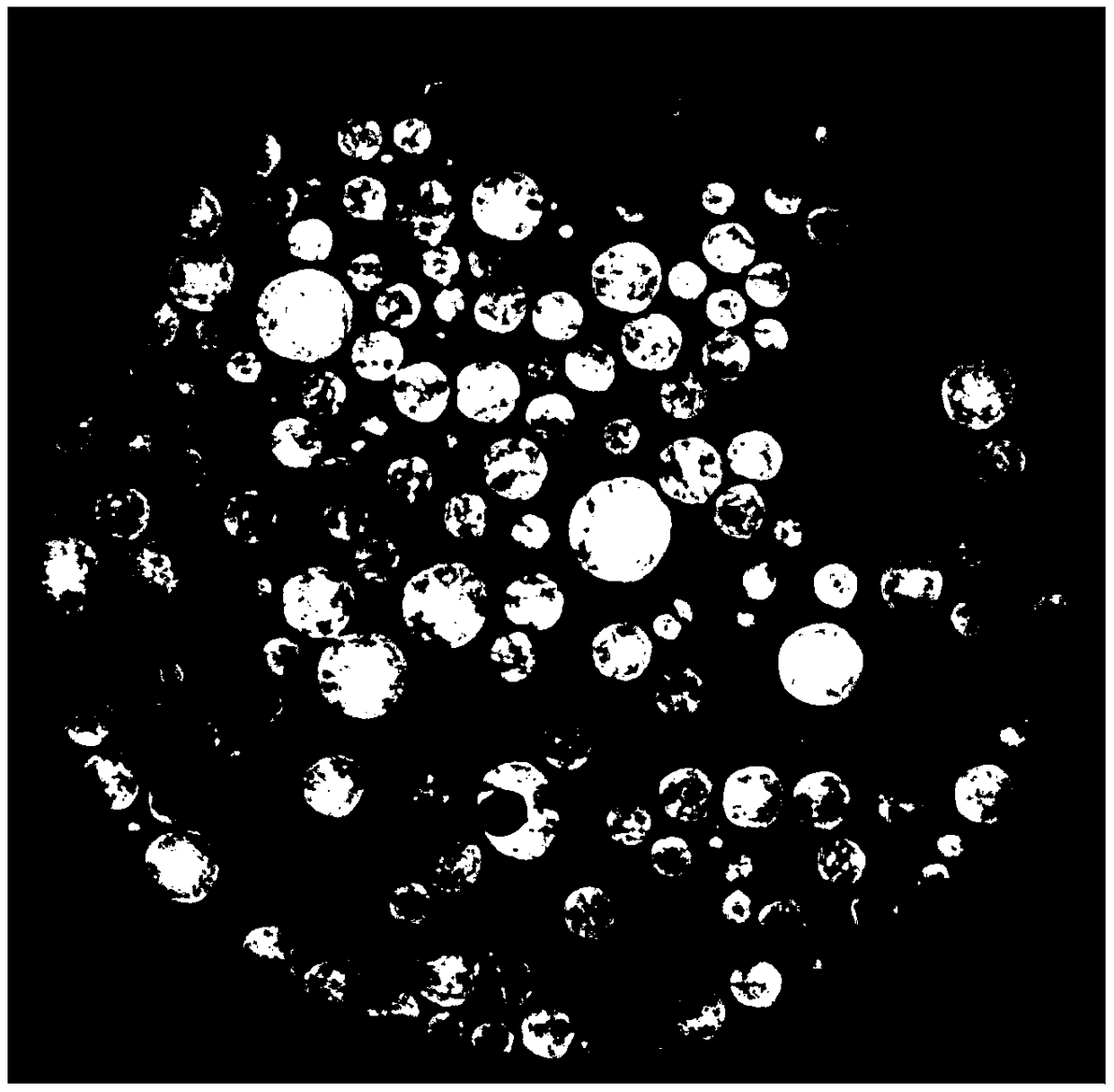

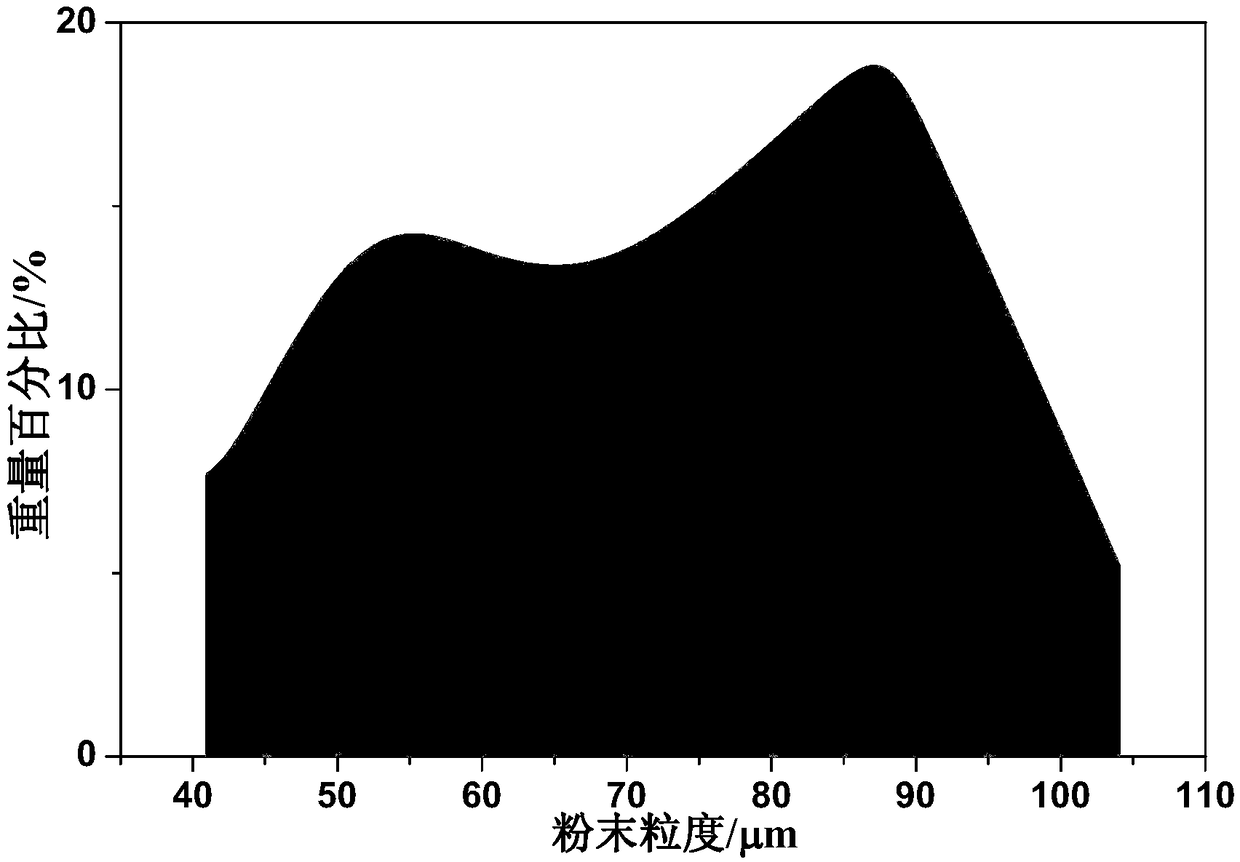

[0028] Step 2. After the Ti6Al4V alloy raw material and tin material described in step 1 are melted by vacuum induction melting, fill the melting chamber with argon gas for protection, and the pressure of the filled argon gas is 0.5 bar; The graphite guide tube is heated, and the Ti6Al4V alloy raw material and tin material are completely melted to produce a molten liquid with low viscosity. The molten liquid falls freely to the atomization chamber through the heated grap...

Embodiment 2

[0037] The method of this embodiment is:

[0038] Step 1. Put the Ti6Al4V alloy ingot and tin block into a water-cooled copper crucible, and then place it in the melting chamber of the vacuum induction melting gas atomization equipment, and evacuate the melting chamber until the vacuum degree in the furnace is not greater than 5Pa. Vacuum induction melting is carried out at a temperature of 1800°C; the amount of the tin material is 1% of the total mass of the titanium alloy raw material and the tin material;

[0039] Step 2. After the titanium alloy raw material and tin material described in step 1 are melted by vacuum induction melting, fill with argon gas for protection, and the pressure of filling argon gas is 0.1 bar; After heating, when the Ti6Al4V alloy raw material and tin material are completely melted, a low-viscosity molten liquid is produced. The molten liquid falls freely to the atomization chamber through the heated graphite guide tube for gas atomization treatmen...

Embodiment 3

[0042] The method of this embodiment is:

[0043] Step 1. Put the Ti6Al4V alloy ingot and tin block into a water-cooled copper crucible, and then place it in the melting chamber of the vacuum induction melting gas atomization equipment, and evacuate the melting chamber until the vacuum degree in the furnace is not greater than 5Pa. Vacuum induction melting is carried out at a temperature of 1600°C; the amount of the tin material is 3% of the total mass of the titanium alloy raw material and the tin material;

[0044] Step 2. After the Ti6Al4V alloy raw material and tin material described in step 1 are melted by vacuum induction melting, fill with argon gas for protection, and the pressure of filling argon gas is 0.5 bar; After heating, when the Ti6Al4V alloy raw material and tin material are completely melted, a low-viscosity molten liquid is produced. The molten liquid falls freely to the atomization chamber through the heated graphite guide tube for gas atomization treatment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com