Torsion type reciprocating extrusion device and process method thereof

A technology of reciprocating extrusion and processing methods, which is applied to the forming tools of metal extrusion, metal extrusion, metal processing equipment, etc., and can solve the problems of different deformation modes and degrees, uniformity defects of ultra-fine-grained materials, and uneven disassembly of molds. Convenience and other issues, to achieve the effect of sufficient grain refinement, improved mechanical properties, and light equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

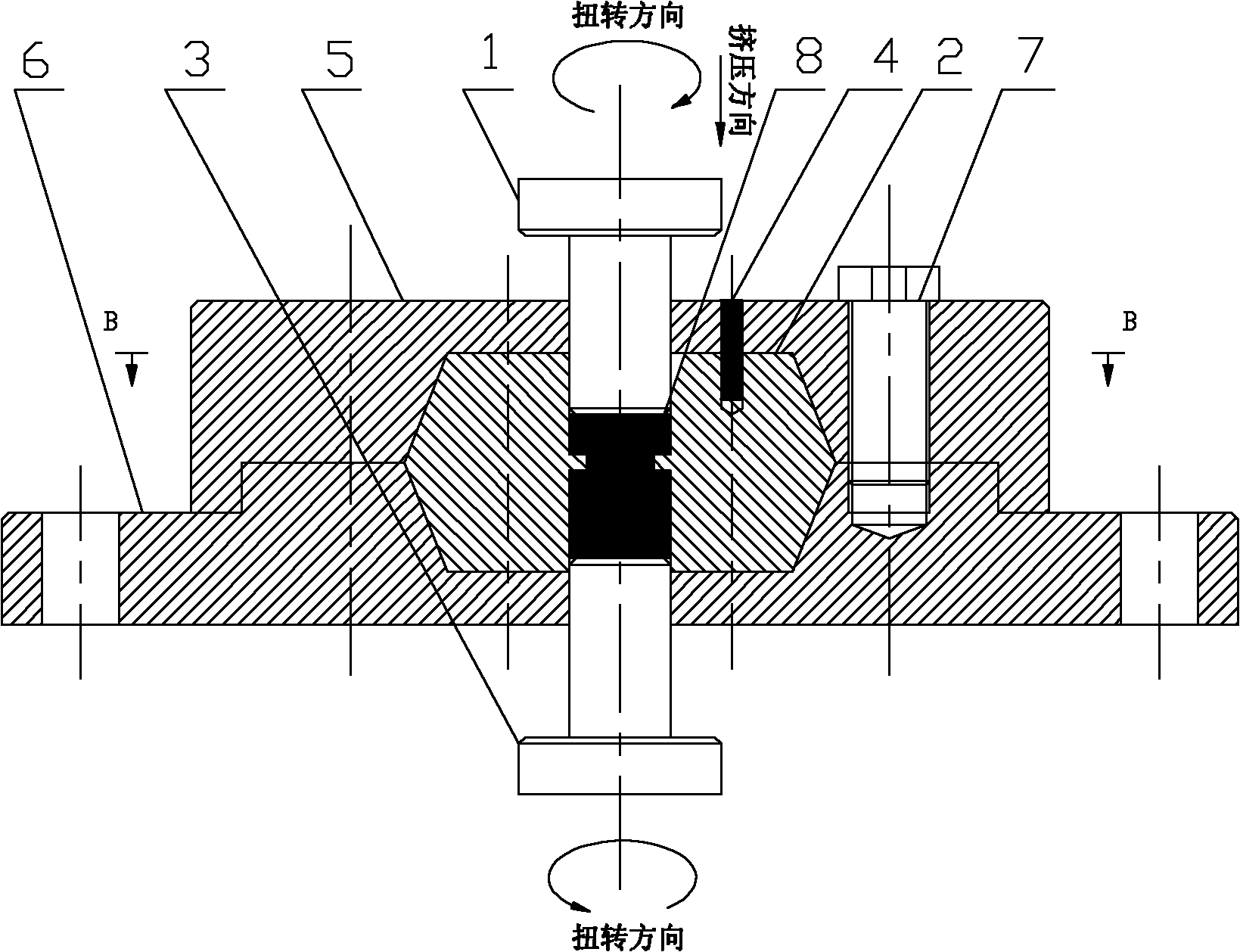

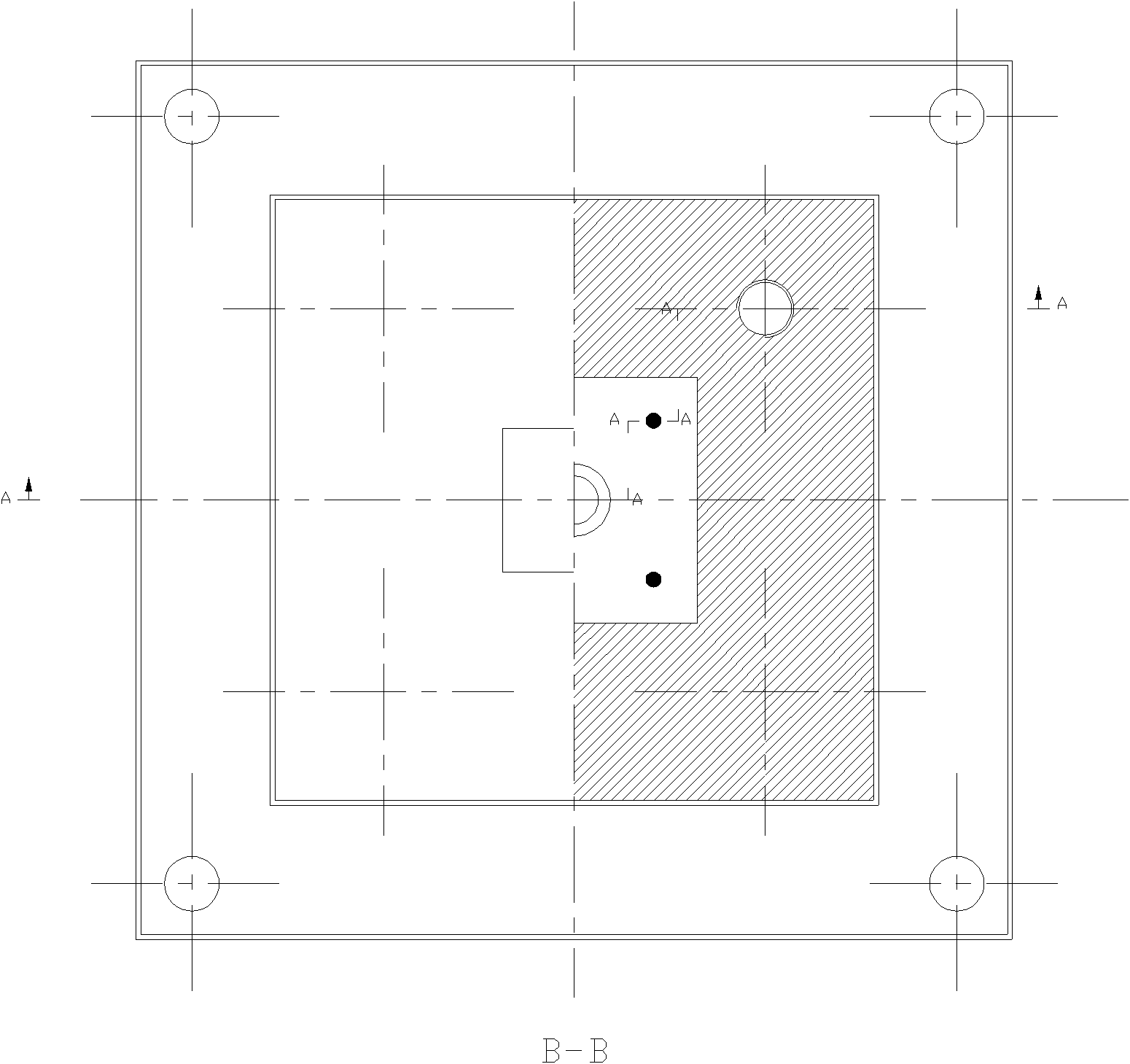

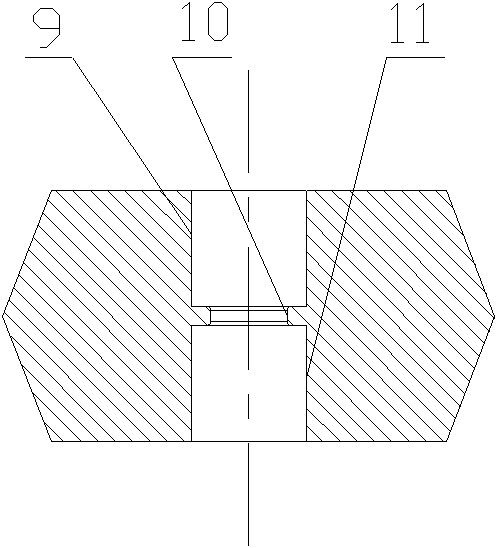

[0031] Such as figure 1 As shown, the extrusion device involved in this embodiment includes: an upper pressing head 1, a die 2, a lower pressing head 3, a positioning pin 4, a die cover plate 5, a die fixing plate 6, and a set plate fixing screw 7, wherein The die fixing plate 6 is fixed on the workbench, and the die 2 has a built-in linear variable cross-section circular extrusion channel. The profile of die 2 adopts a square structure with variable cross-section (see image 3 ), assembled between the die fixing plate 6 and the die cover plate 5. After being positioned by the positioning pin 4, it is connected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com