Colloid mill stator and rotor and colloid mill comprising stator and rotor

A technology for grinding stators and stators, applied in the field of colloid mills, can solve problems such as efficiency to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

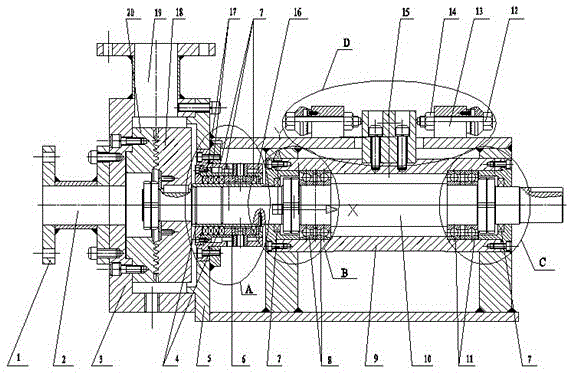

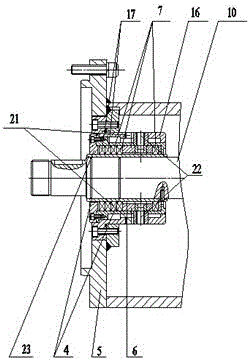

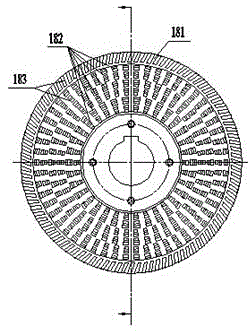

[0032] Such as Figure 1-7 As shown, the colloid mill includes a feed pipe 2, a stator case 3, a casing 5 and a discharge pipe 19, etc., and the left end of the colloid mill is provided with a flange 1 connected to the equipment used in the previous process. A bearing seat 9 is fixedly installed in the box body 5 , and the main shaft 10 is installed in the box body 5 through an angular contact ball bearing 8 (front bearing B) and a deep groove ball bearing 11 (rear bearing C) fixedly arranged on the bearing seat 9 . The main shaft 10 extends through the box body into the working chamber of the stator housing 3 , and the main shaft 10 is fixedly connected to the rotor 18 at the end of the working chamber. The box body 5 is provided with two installation holes of the bearing seat 9, and these two installation holes can ensure that the bearing seat 9 fixed with the main shaft 10 cannot move radially in the holes. The stator 20 is fixedly installed in the working chamber of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com