Co-precipitation preparation method of ZrO2/Gd203 composite ceramic material for nuclear power

A composite ceramic and co-precipitation technology is applied in the field of composite ceramic materials to achieve the effects of easy implementation, good internal uniformity and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

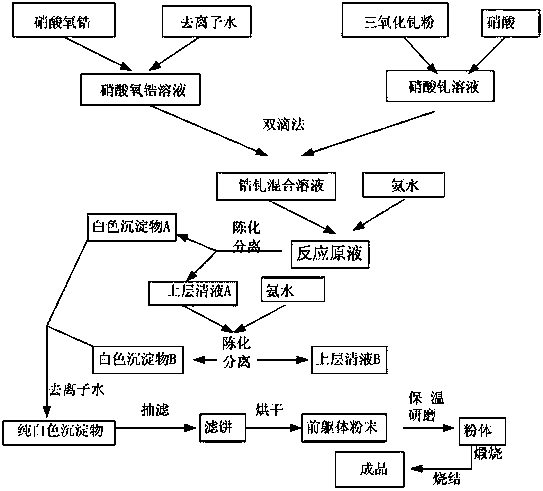

[0034] Such as figure 1 shown.

[0035] A kind of ZrO for nuclear power 2 / Gd 2 o 3 The co-precipitation preparation method of the composite ceramic material comprises a zirconium-gadolinium mixed solution pre-preparation process, and the zirconium-gadolinium mixed solution pre-preparation process includes a zirconium oxynitrate solution preparation step, a gadolinium nitrate solution preparation step and a zirconium-gadolinium mixed solution preparation step, and the specific steps are as follows:

[0036] Preparation steps of zirconyl nitrate solution: dissolving zirconyl nitrate in deionized water to obtain zirconyl nitrate solution;

[0037] Preparation steps of gadolinium nitrate solution: dissolving gadolinium trioxide powder in nitric acid solution to obtain gadolinium nitrate solution;

[0038] Preparation steps of the zirconium-gadolinium mixed solution: mixing the zirconyl nitrate solution and the gadolinium nitrate solution by a double-drop method to obtain the ...

Embodiment 2

[0059] Choose analytically pure zirconyl nitrate and gadolinium trioxide powder as raw materials. Weigh 261g of zirconyl nitrate (ZrO 2 Calculated as 100g) dissolved in an appropriate amount of deionized, weighed 10g of gadolinium trioxide powder and dissolved in an appropriate amount of analytically pure nitric acid solution. Mix the prepared gadolinium nitrate solution with the zirconyl nitrate solution by double drop method, and keep stirring for 25 minutes to form a uniform mixed solution. Add ammonia water dropwise to the mixed solution at a rate of 1.5ml / min, adjust the pH value of the mixed solution, keep the pH value at around 6-8, stir vigorously while adding dropwise to make it fully react, and white precipitates precipitate out. Continue to stir for 1.5-2.5h. The reaction stock solution was left still, aged for 10-15 hours, the supernatant was absorbed, and ammonia water was added dropwise to the clear solution to wash until no white precipitate was produced in th...

Embodiment 3

[0061] Get 261g analytically pure zirconyl nitrate (ZrO 2 calculated as 100g) was dissolved in deionized water to prepare a zirconium oxynitrate solution; 10 g of analytically pure gadolinium trioxide powder was dissolved in an appropriate amount of analytically pure nitric acid solution to prepare a gadolinium nitrate solution; the prepared gadolinium nitrate solution was mixed with double drops It is mixed with zirconyl nitrate solution and stirred continuously for 20 minutes to form a uniform mixed solution.

[0062] Use ammonia water to add dropwise to the mixed solution at a rate of 2ml / min, adjust the pH value of the mixed solution to keep it at about 7, stir vigorously while adding dropwise, make it fully react, white precipitates precipitate, continue to stir for 2h. Put the reaction stock solution still, carry out aging treatment for 10 hours, absorb the supernatant liquid, add ammonia water dropwise to the clear liquid to wash until no white precipitate is produced i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com