Polypropylene material with high melt strength and preparation method thereof

A technology of polypropylene material and high melt strength, which is applied in the field of polypropylene material and its preparation, can solve the problems of no obvious improvement in mechanical properties, unpleasant odor of products, etc., and achieve excellent mechanical properties, good mixing performance, long residence time long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

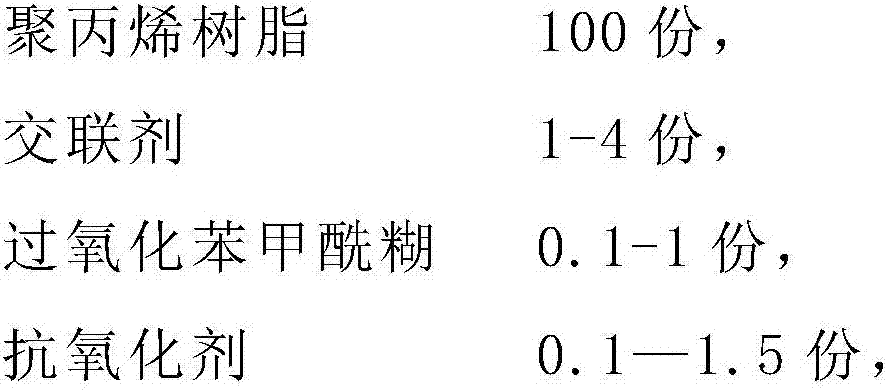

[0023] The present invention prepares high melt strength polypropylene material by following method:

[0024] (1) Get polypropylene resin, cross-linking agent, benzoyl peroxide paste, antioxidant; The mass content of benzoyl peroxide is 50-55%, and tetrakis{β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate}pentaerythritol ester can be used as an antioxidant.

[0025] (2) Add all components of polypropylene resin, benzoyl peroxide paste, and antioxidants to the high mixer in turn and mix at a speed of 450 rpm for 5 minutes, then add the crosslinking agent under the condition of not stopping the machine and not changing the speed. Mix for 10 minutes; during the mixing process, the temperature of the material in the high mixer is controlled at 40-60°C;

[0026] (3) The mixed material is extruded through a three-screw parallel rotating extruder, and the material undergoes cross-linking and grafting reactions during the extrusion process of the extruder to make a high-melt strength ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com