Preparation method of dispersible polypyrrole copolymer

A technology of polypyrrole copolymer and copolymer, which is applied in the direction of sustainable manufacturing/processing, climate sustainability, chemical industry, etc., can solve the problems of complex process and narrow applicable range, and achieve simple preparation process and simplified operation steps And experimental equipment, the effect of raw materials are easy to get

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Mix polyethylene glycol 600 (PEG 600) with water, stir for 15 minutes; add ferrous chloride and pyrrole monomer, and stir for 15 minutes to obtain a mixed solution; the concentration of PEG600 in the mixed solution is 15wt%, The concentration of pyrrole monomer is 0.15mmol / mL, and the concentration of ferrous chloride is 0.3mmol / mL;

[0041] (2) The mixed solution obtained above was irradiated in a cobalt-60 irradiation chamber at a dose rate of 2.94 kGy / hour at room temperature and in an air atmosphere. When the cumulative absorbed dose reaches 50kGy, take out the reaction solution sample;

[0042] (3) After the reaction solution was centrifuged for 5 minutes (10000 rpm) with a high-speed centrifuge, the lower precipitate was collected and redispersed in deionized water. Repeat above-mentioned centrifugation and wash 3 times, obtain polypyrrole-co-PEG600 copolymer through freeze-drying then.

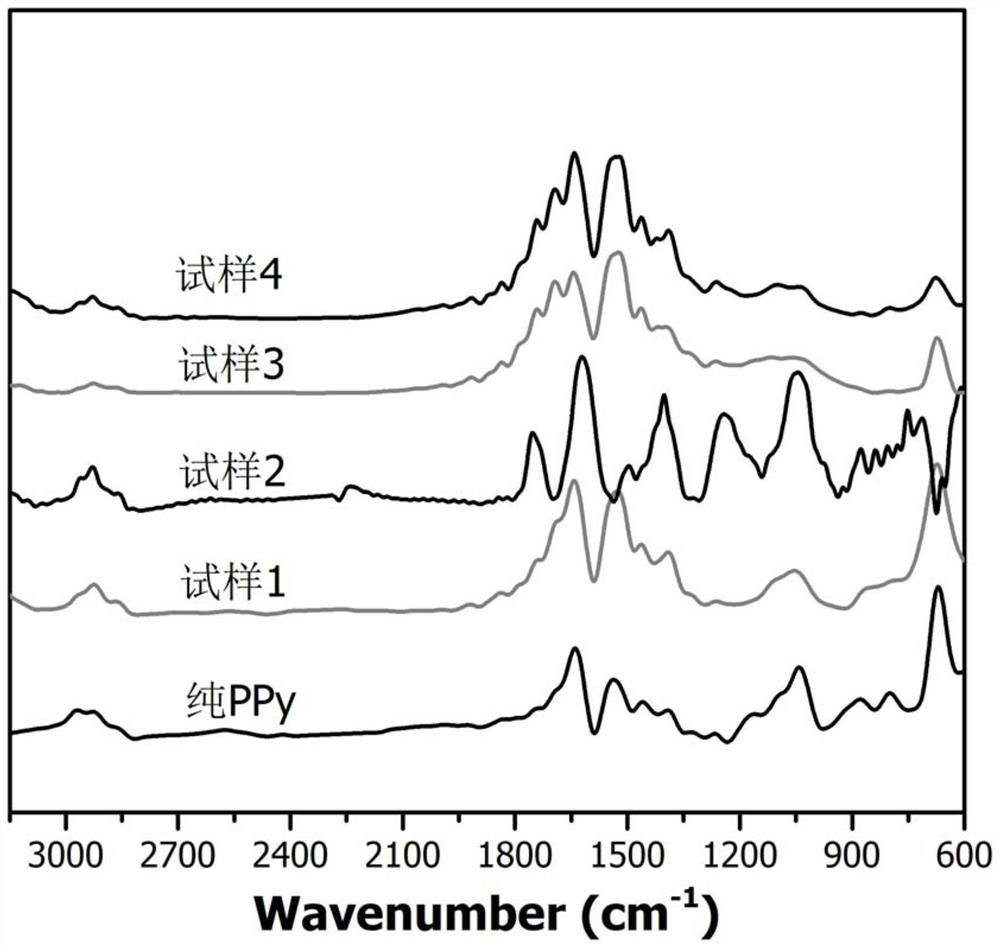

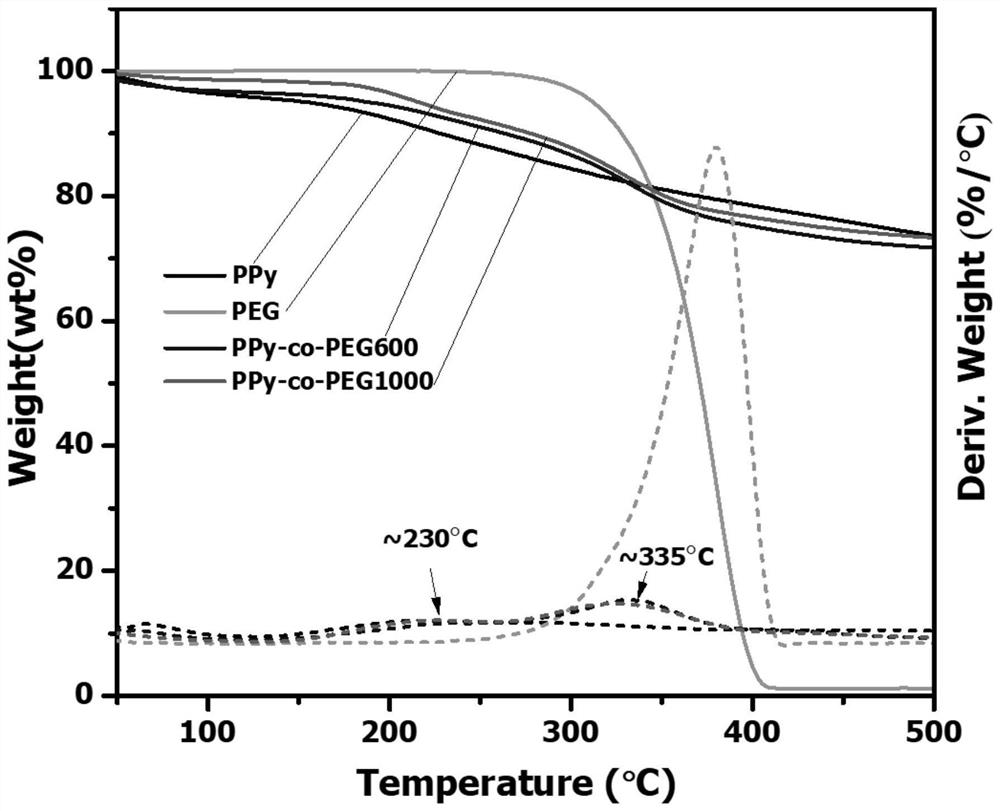

[0043] The polypyrrole-co-PEG600 copolymer in Example 1 was analyzed by ...

Embodiment 2

[0049] (1) Mix polyvinyl alcohol 1788 type (PVA-1788) with water, and obtain a clear PVA aqueous solution with conventional preparation operations; then add ferrous chloride and pyrrole monomer, and stir for 15 minutes to obtain a mixed solution; in the resulting mixed solution The concentration of PVA is 5wt%, the concentration of pyrrole monomer is 0.1mmol / mL, and the concentration of ferrous chloride is 0.2mmol / mL;

[0050] (2) The mixed solution obtained above was irradiated in a cobalt-60 irradiation chamber at a dose rate of 0.72 kGy / hour at room temperature and in an air atmosphere. When the accumulated absorbed dose reaches 16.7kGy, take out the reaction solution sample;

[0051] (3) After the reaction solution was centrifuged for 5 minutes (10000 rpm) with a high-speed centrifuge, the lower precipitate was collected and redispersed in deionized water. Repeat above-mentioned centrifugation and wash 3 times, then obtain polypyrrole-co-PVA copolymer through lyophilizati...

Embodiment 3

[0055] (1) Sodium carboxymethylcellulose (CMC) is stirred and mixed with water, and the CMC aqueous solution is prepared by conventional methods; Add cerium sulfate and pyrrole monomer subsequently, and stir to obtain mixed solution for 5 minutes; The concentration of CMC in this mixed solution is: 0.5wt%, the concentration of pyrrole monomer is 0.1mmol / mL, the concentration of cerium sulfate is 0.02 mmol / mL;

[0056] (2) The mixed solution obtained above was irradiated in a cobalt-60 irradiation chamber at a dose rate of 1.3 kGy / hour at room temperature and in an air atmosphere. When the accumulated absorbed dose reaches 30kGy, take out the reaction solution sample;

[0057] (3) After the reaction solution was centrifuged for 5 minutes (10000 rpm) with a high-speed centrifuge, the lower precipitate was collected and redispersed in DMAc. Repeat above-mentioned centrifugation and washing 3 times, obtain polypyrrole-co-CMC copolymer through lyophilization then.

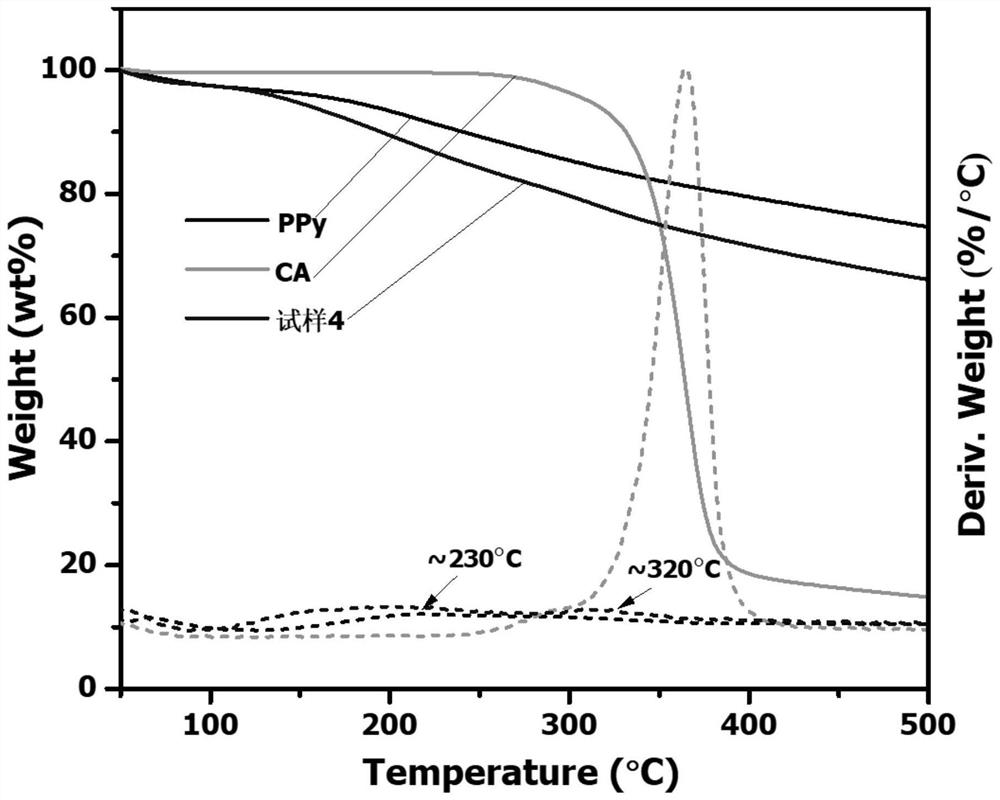

[0058] Utiliz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com