Efficient abrasive belt grinding special grinding apparatus for high surface integrity machining

An abrasive belt grinding and integrity technology, used in abrasive belt grinders, manufacturing tools, metal processing equipment, etc., can solve the problem that the longitudinal microscopic grain direction is not strong, and special tools for longitudinal abrasive belt grinding are not popularized, and processing efficiency Low and other problems, to achieve the effect of reliable abrasive belt fixation, good microstructure and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The core of the present invention is to provide a high-efficiency abrasive belt grinding special abrasive tool for high surface integrity processing, which has a simple structure, firm abrasive belt fixation, high processing efficiency and good mechanical properties.

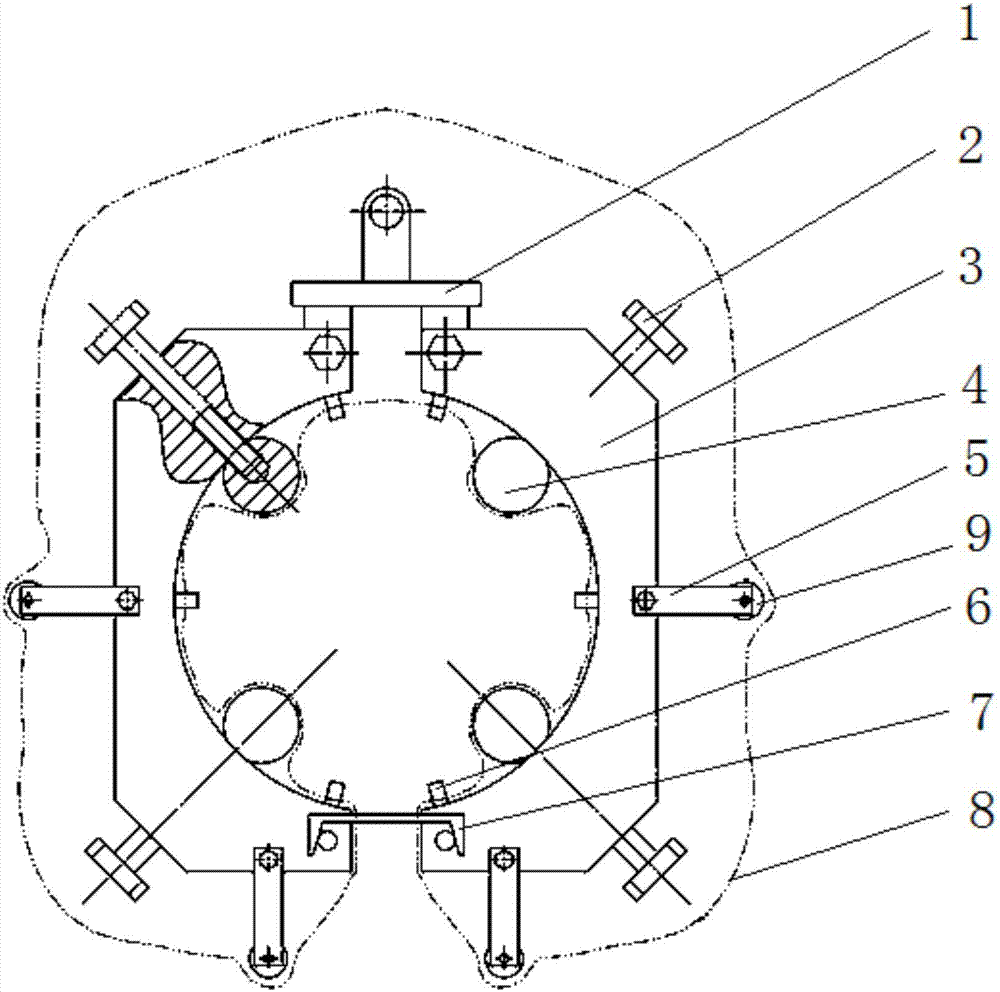

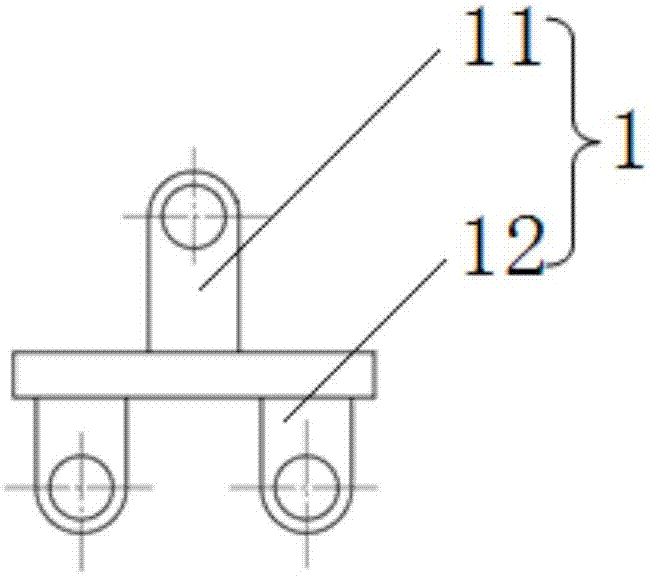

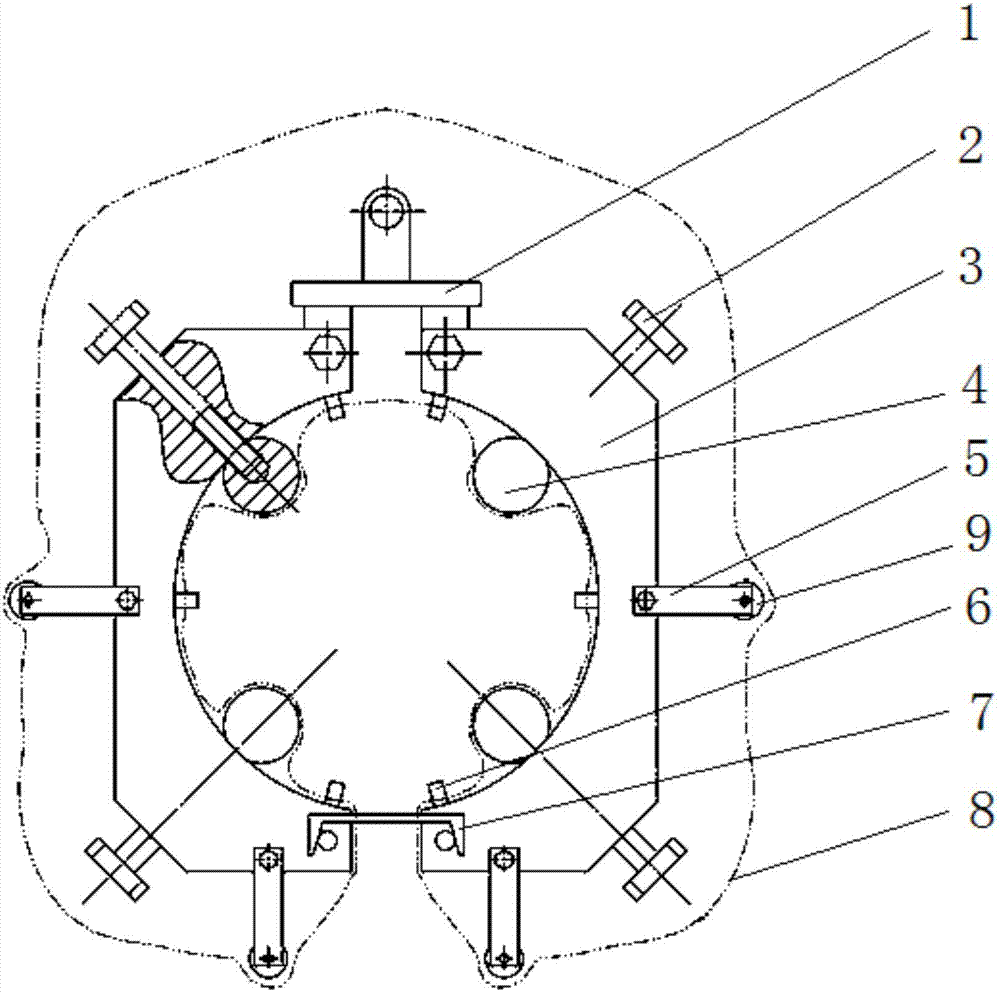

[0037] It should be noted that the orientation words "up, down, left, right" appearing in this article refer to figure 1 up, down, left, and right directions. "inside" means figure 1 The middle points to the direction of the inside of the polishing block, and "outside" refers to the figure 1 The middle points to the direction outside the polishing block; the orientation words appearing in this article are all based on the customary usage of those skilled in the art and the accompanying drawings of the description, and their appearance should not affect the protection scope of the present invention; in addition, the The "special abrasive belt" mentioned above is limited to the installation of the abrasiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com