Heat treatment technique of large-size GCr15 steel

A technology of large size and craftsmanship, applied in the field of steel heat treatment and metal processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] a) Coat the surface of GCr15 steel with a diameter of 60mm with carbon powder and put it into the electric furnace, or put the GCr15 steel into the electric furnace and cover it with charcoal.

[0018] b) Heat the electric furnace to 840°C and keep it warm for 40 minutes; after keeping it warm, place it in water at 20-50°C to water-quench the GCr15 steel.

[0019] c) Observe the color change of the steel during the water quenching process. When the color of the steel surface becomes dark and the red color disappears completely, quickly take the product out of the water pool and place it in oil at 20-40°C for oil quenching until the temperature of GCr15 steel Not higher than oil temperature.

[0020] d) After quenching, quickly temper the sample, the tempering temperature is 180°C, and the tempering time is 2 hours.

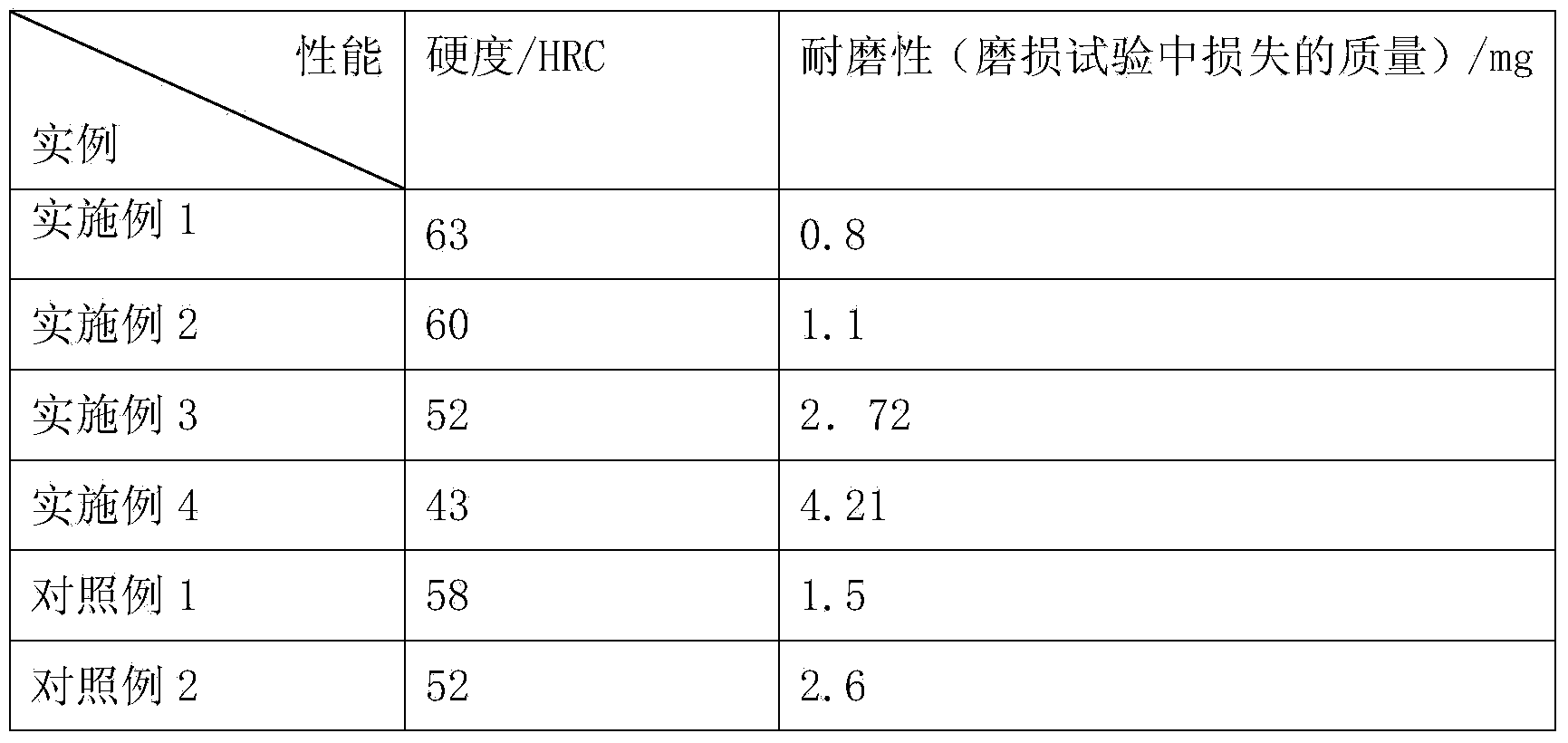

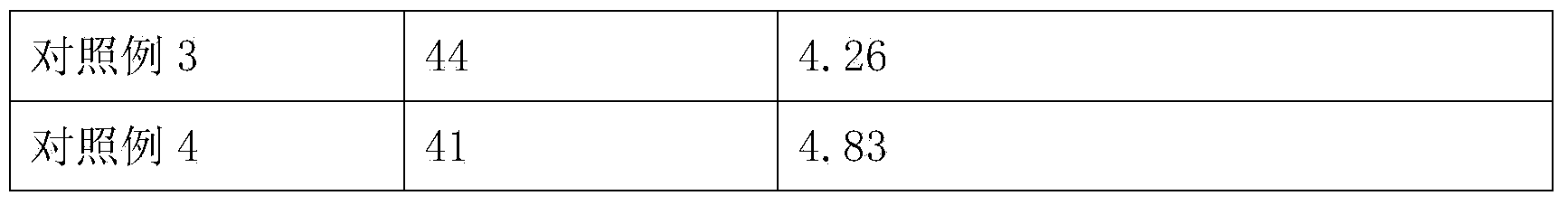

[0021] The product is sampled and tested for hardness and wear resistance. The test results are shown in Table 1

Embodiment 2

[0023] a) Coat the surface of GCr15 steel with a diameter of 60mm with carbon powder and put it into the electric furnace, or put the GCr15 steel into the electric furnace and cover it with charcoal,

[0024] b) Heat the electric furnace to 840°C and keep it warm for 40 minutes; after keeping it warm, place it in water at 20-50°C to quench the GCr15 steel.

[0025] c) Observe the color change of the steel during the water quenching process. When the color of the steel surface becomes dark and the red color disappears completely, quickly take the product out of the water pool and place it in oil at 20-40°C for oil quenching until the temperature of GCr15 steel Not higher than oil temperature.

[0026] d) Temper the sample quickly after quenching, the tempering temperature is 250°C, and the tempering time is 2 hours.

[0027] The product is sampled and tested for hardness and wear resistance. The test results are shown in Table 1

Embodiment 3

[0029] a) Coat the surface of GCr15 steel with a diameter of 60mm with carbon powder and put it into the electric furnace, or put the GCr15 steel into the electric furnace and cover it with charcoal.

[0030] b) Heat the electric furnace to 840°C and keep it warm for 40 minutes; after keeping it warm, place it in water at 20-50°C to quench the GCr15 steel.

[0031] c) Observe the color change of the steel during the water quenching process. When the color of the steel surface becomes dark and the red color disappears completely, quickly take the product out of the water pool and place it in oil at 20-40°C for oil quenching until the temperature of GCr15 steel Not higher than oil temperature.

[0032] d) After quenching, quickly temper the sample, the tempering temperature is 380°C, and the tempering time is 2 hours.

[0033] The product is sampled and tested for hardness and wear resistance. The test results are shown in Table 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com